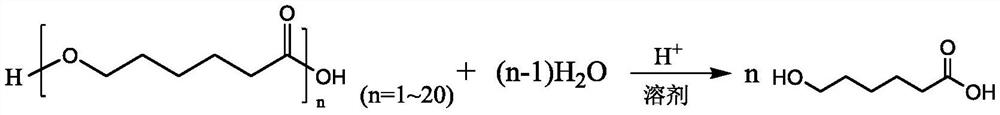

Production process of 6-hydroxyhexanoic acid

A technology of hydroxycaproic acid and production process, applied in the field of chemical industry, can solve the problems of complex process and low yield, and achieve the effects of simple process conditions, high yield and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

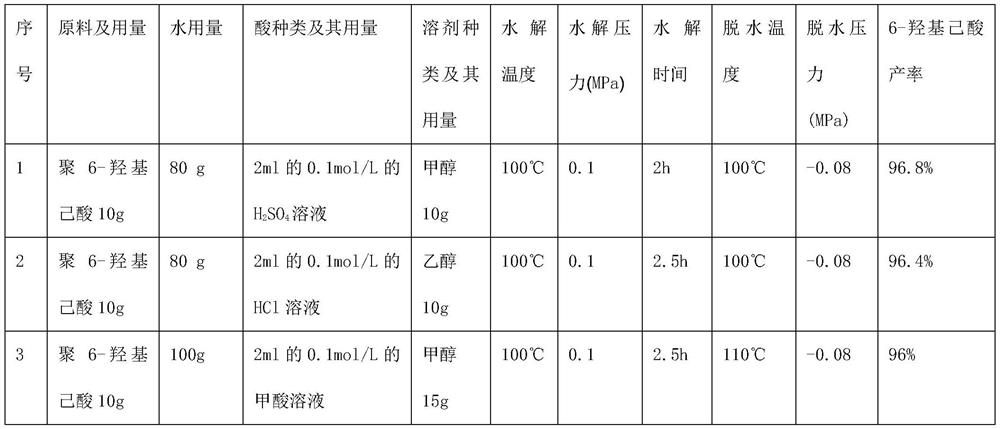

Embodiment 1

[0025] 10g of poly-6-hydroxycaproic acid, 80g of water, 2ml of 0.1mol / L H 2 SO 4 Put the solution and 10g of methanol into a 250ml distillation flask at one time, put the flask into an oil bath, stir and heat to 100°C with a DF-101S collector type constant temperature heating magnetic stirrer, and react at a constant temperature under a pressure of 0.1MPa for 2h , followed by distillation and dehydration at a temperature of 100°C and a condition of -0.08MPa. The yield of 6-hydroxycaproic acid was 96.8%.

Embodiment 2

[0027] Put 10g of poly-6-hydroxycaproic acid, 80g of water, 2ml of 0.1mol / L HCl solution, and 10g of ethanol into a 250ml distillation flask at one time, put the flask into an oil bath, and use the DF-101S thermal collector Constant temperature heating, stirring and heating with a magnetic stirrer to 100°C, constant temperature reaction under a pressure of 0.1MPa for 2.5h, followed by distillation and dehydration at a temperature of 100°C and a condition of -0.08MPa. The yield of 6-hydroxycaproic acid was 96.4%.

Embodiment 3

[0029] Put 10g of poly-6-hydroxycaproic acid, 100g of water, 2ml of 0.1mol / L formic acid solution, and 15g of methanol into a 250ml distillation flask at one time, put the flask into an oil bath, and use the DF-101S thermal collector Stir and heat with a magnetic stirrer at a constant temperature and heat to 100°C, react at a constant temperature under a pressure of 0.1MPa for 2.5h, and then distill and dehydrate at a temperature of 110°C and a condition of -0.08MPa. The yield of 6-hydroxycaproic acid was 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com