Method for copolymerizing sulfur-free soap-free in-situ RAFT emulsion to synthesize polymer/pigment hybrid latex

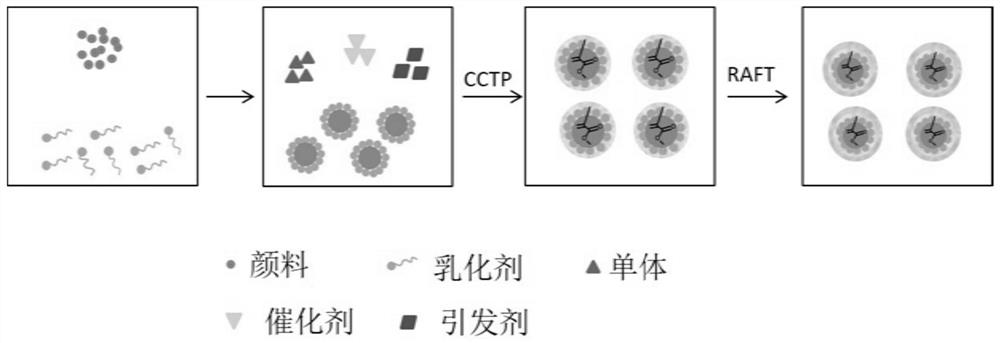

A polymer and copolymerization technology, applied in the field of sulfur-free and soap-free in-situ RAFT emulsion copolymerization into polymer/pigment hybrid latex, which can solve the problem of low coating rate of coated pigments, difficult control of color light, and uncontrollable molecular structure and other problems, to achieve the effect of high pigment coating rate, high dispersion stability and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

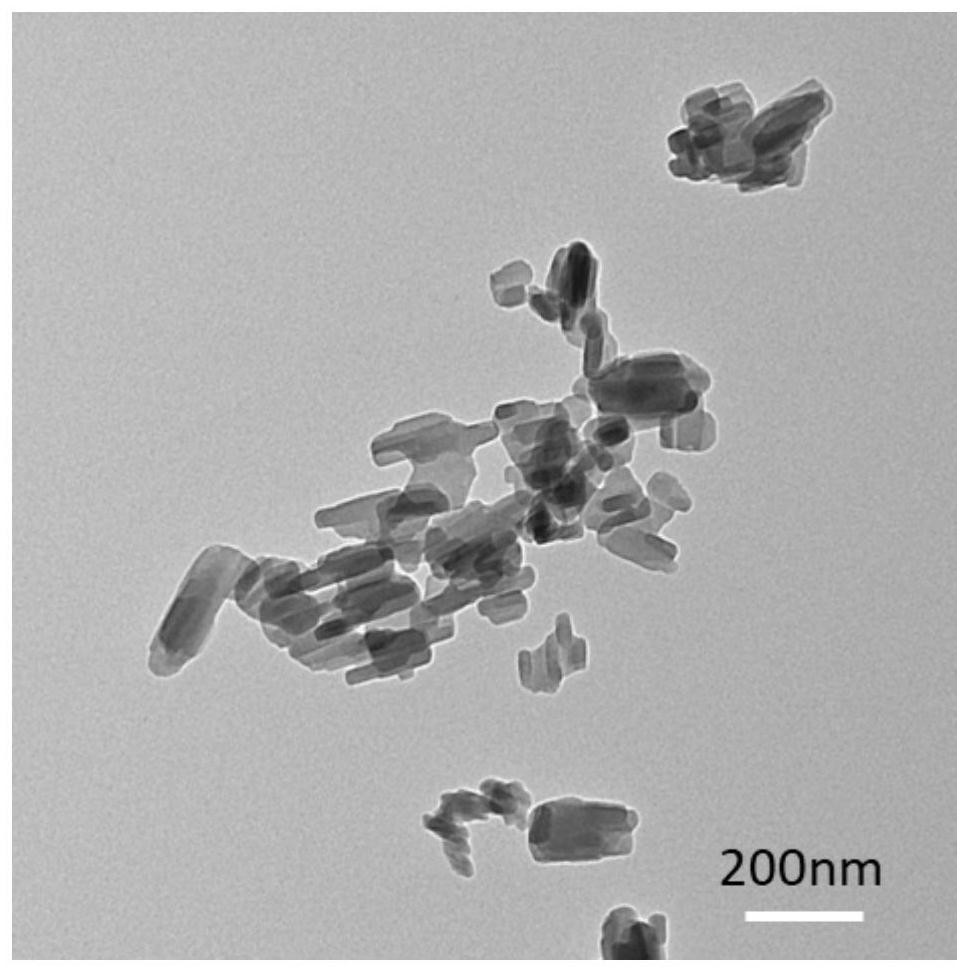

[0050] According to table 1, feed ratio and condition shown in table 2, prepare polymer / organic pigment hybrid latex, the steps are as follows:

[0051] 1. Dissolve the reactive emulsifier in water, add the pigment, and homogenize it by ultrasonic to obtain the pigment dispersion liquid. The amount of the reactive emulsifier accounts for 5%-10% of the monomer. The ultrasonic homogenization temperature is -5-10°C, and the ultrasonic time is 5-60 minutes.

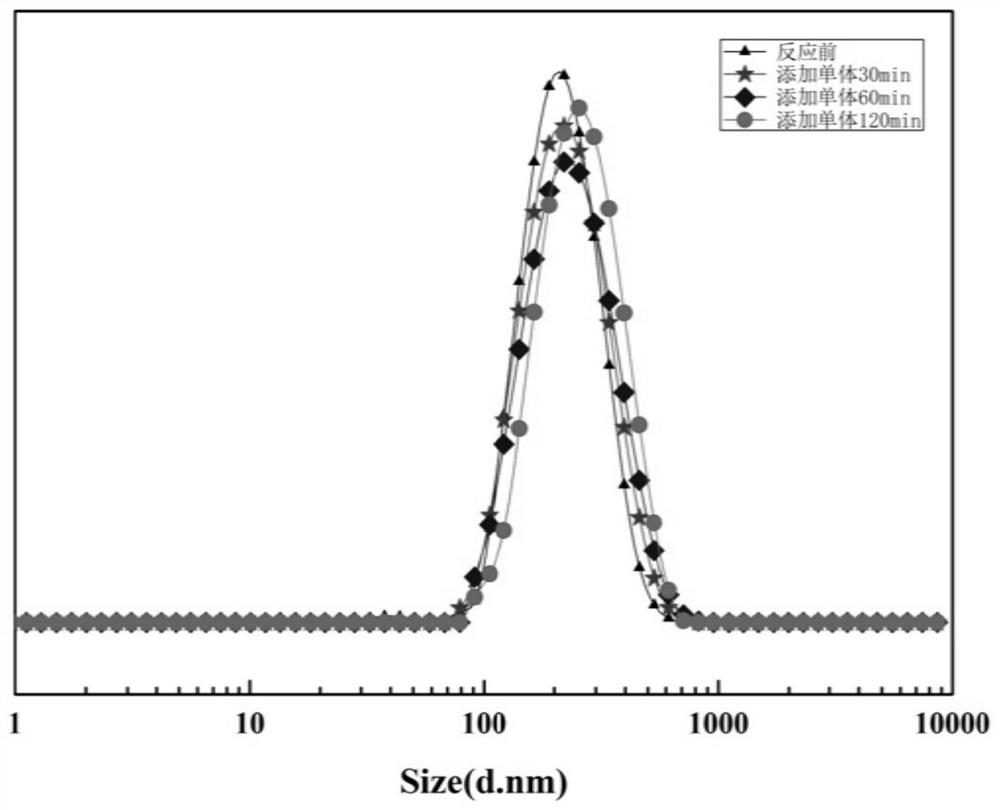

[0052] 2. Using the catalytic chain transfer polymerization (CCTP) method to in-situ synthesize the amphiphilic sulfur-free ω-vinyl methacrylate macromolecular RAFT reagent on the surface of the pigment particles, the specific experimental steps are as follows: the catalytic chain transfer reagent and formazan methacrylate monomer was added to a 100 mL round bottom flask with a stir bar (80-120 ppm catalyst based on methacrylate monomer) and nitrogen was purged for at least 1 hour, allowing the mixture to stir under nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com