Copper-coated multilayer graphene composite material and preparation method thereof

A multi-layer graphene and composite material technology, applied in conductive materials, conductive materials, nanotechnology for materials and surface science, etc., can solve the problems of high cost and difficult dispersion of carbon nanotubes and graphene, and achieve the The effect of electrical conductivity, good dispersion and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

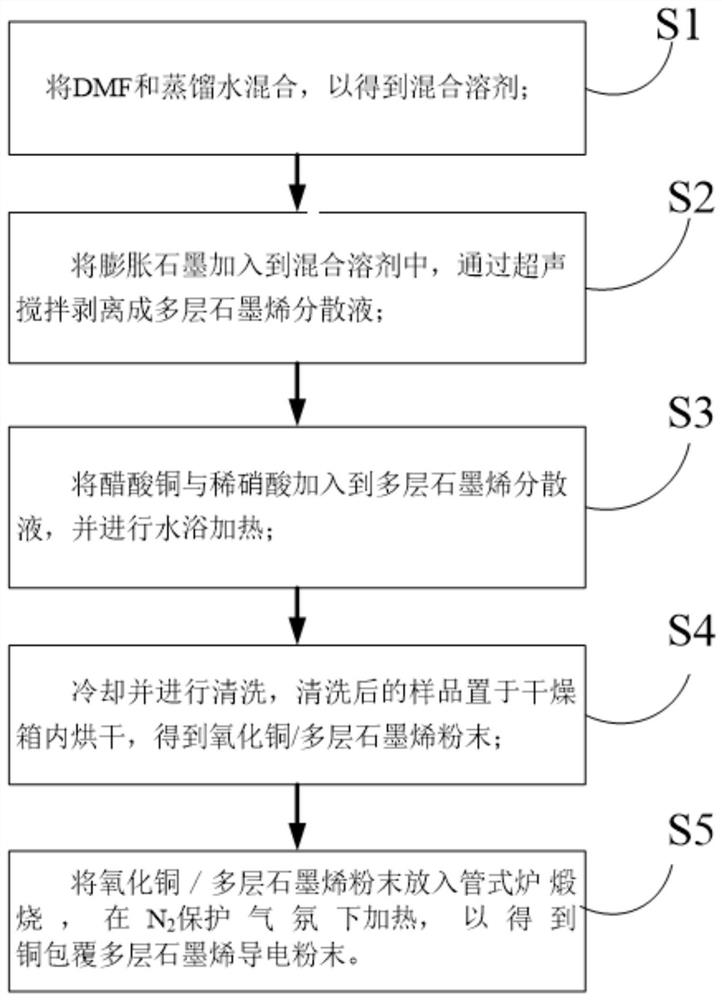

[0037] A kind of preparation method of copper clad multilayer graphene composite material of the present embodiment, comprises the following steps:

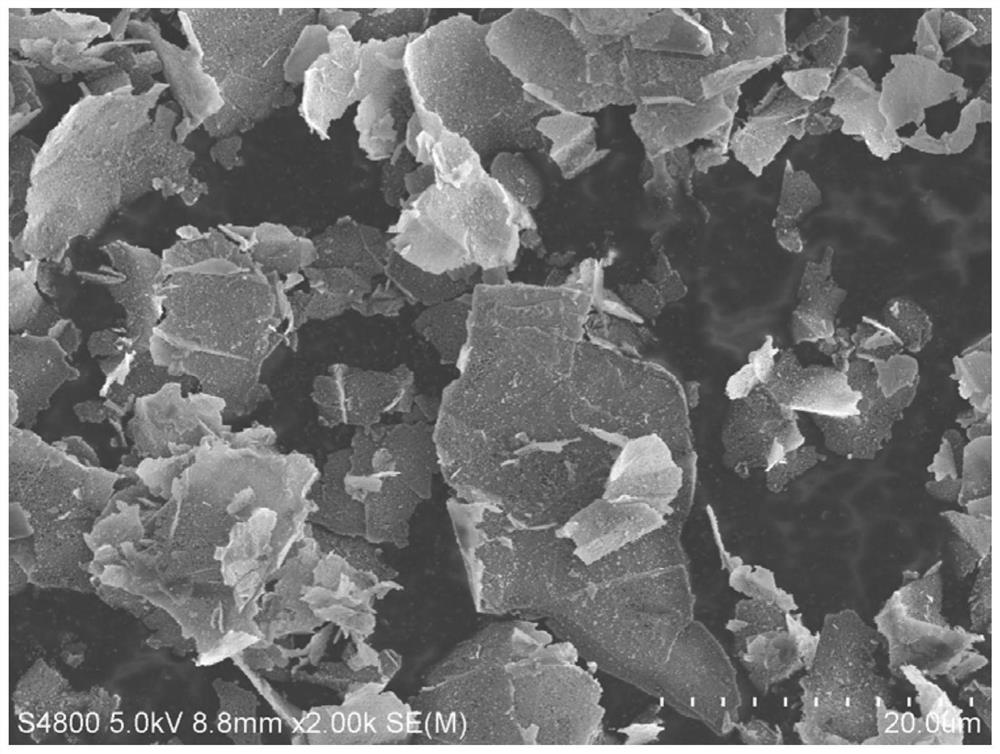

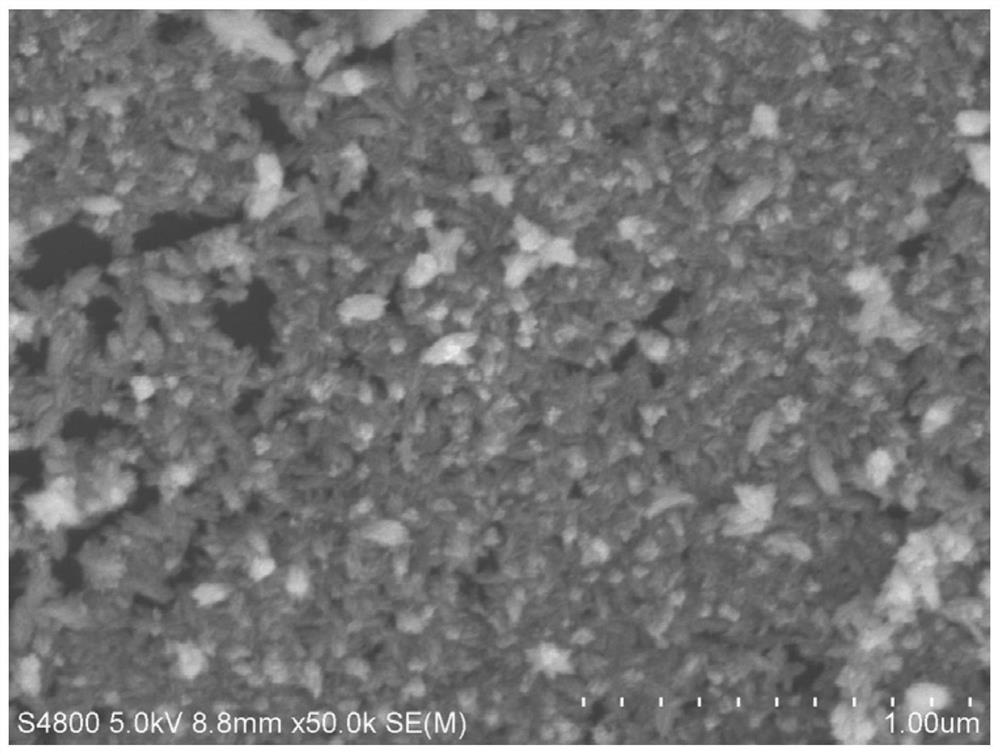

[0038] Measure 8mL of DMF and 2mL of distilled water and mix them together to form a homogeneous mixed solvent. Weigh 20 mg of expanded graphite, add a mixed solvent, perform mechanical exfoliation on an ultrasonic machine for 5 hours, and exfoliate the expanded graphite into a multilayer graphene dispersion with a thickness of 1-10 nm. Weigh 200 mg of copper acetate and 0.4 μL of 10 wt % dilute nitric acid, and pour the two into the graphene dispersion solution successively. Dilute nitric acid is added to uniformly deposit copper oxide on the surface of multilayer graphene to form a nano-copper oxide film. Put the solution into a water bath at a temperature of 90° C., stir it with magnetic force for 2 hours, and take it out to cool at room temperature. The samples were cleaned with a centrifuge, three times each with water and...

Embodiment 2

[0041] A kind of preparation method of copper clad multilayer graphene composite material of the present embodiment, comprises the following steps:

[0042] Measure 8mL of DMF and 2mL of distilled water and mix them together to form a homogeneous mixed solvent. Weigh 20 mg of expanded graphite, add a mixed solvent, perform mechanical exfoliation on an ultrasonic machine for 9 hours, and exfoliate the expanded graphite into a multilayer graphene dispersion with a thickness of 1-10 nm. Weigh 200 mg of copper acetate and 0.4 μL of 10 wt % dilute nitric acid, and pour the two into the graphene dispersion solution successively. Dilute nitric acid is added to uniformly deposit copper oxide on the surface of multilayer graphene to form a nano-copper oxide film. Put the solution into a water bath with a temperature of 95° C., stir it with magnetic force for 2 hours, and take it out to cool at room temperature. The samples were cleaned with a centrifuge, three times each with water a...

Embodiment 3

[0044] A kind of preparation method of copper clad multilayer graphene composite material of the present embodiment, comprises the following steps:

[0045] Measure 16mL of DMF and 4mL of distilled water and mix them together to form a uniform mixed solvent. Weigh 40 mg of expanded graphite, add a mixed solvent, perform mechanical exfoliation on an ultrasonic machine for 8 hours, and exfoliate the expanded graphite into a multilayer graphene dispersion with a thickness of 1-10 nm. Weigh 400 mg of copper acetate and 0.8 μL of 10 wt % dilute nitric acid, and pour the two into the graphene dispersion solution successively. Dilute nitric acid is added to uniformly deposit copper oxide on the surface of multilayer graphene to form a nano-copper oxide film. Put the solution into a water bath with a temperature of 85° C., stir it with a magnetic force for 2 hours, and take it out to cool at room temperature. The samples were cleaned with a centrifuge, three times each with water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com