Triple-clad silica fiber with inner cladding doped with alkali metal

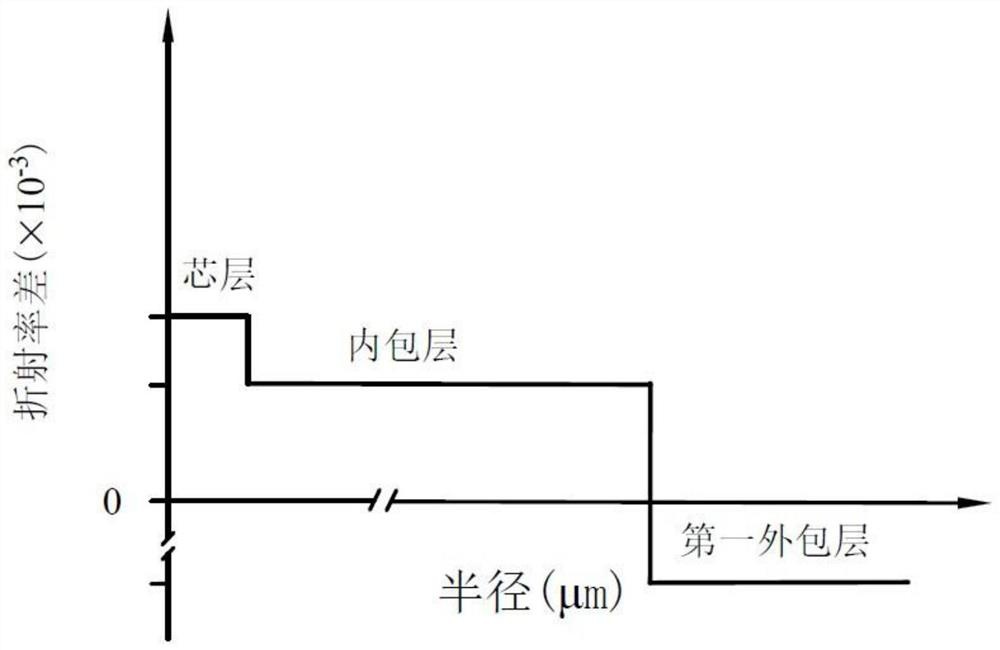

A silica fiber and inner cladding technology, which is applied in the field of rare earth doped fibers and lasers, can solve the problems of high concentration doping difficulty, limited range of refractive index drop, reduced pump source coupling efficiency, etc. The effect of reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

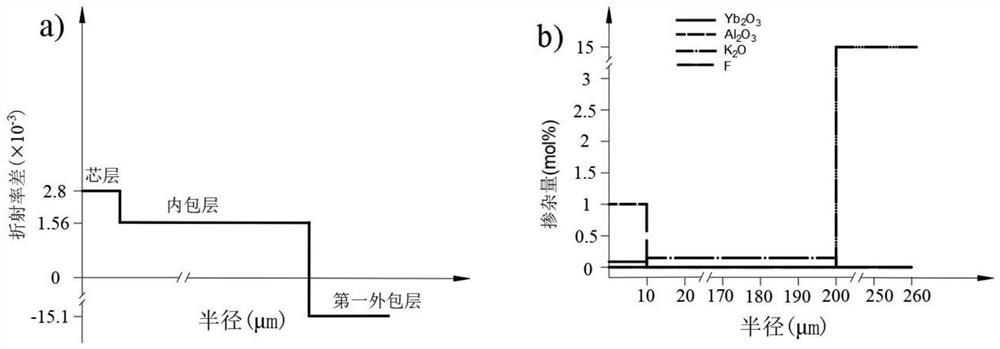

Embodiment 1

[0030] In the triple-clad optical fiber of this embodiment, the radii of the core layer, the inner cladding layer and the outer cladding layer are 10 μm, 200 μm and 260 μm, respectively. The core layer composition of the triple-clad fiber is 1Al 2 o 3 +0.1Yb 2 o 3 , and the rest are quartz (SiO 2 ), and the refractive index difference with pure quartz is +2.8×10 -3 ;Inner cladding composition is 0.15K 2 O, the rest is SiO 2 , the refractive index difference with pure quartz is +1.56×10 -3 ; The outer cladding component is 14F, and the rest is SiO 2 , the refractive index difference with pure quartz is -1.37×10 -2 . Therefore, the numerical aperture of the core layer is 0.06, and the numerical aperture of the inner cladding layer is 0.22.

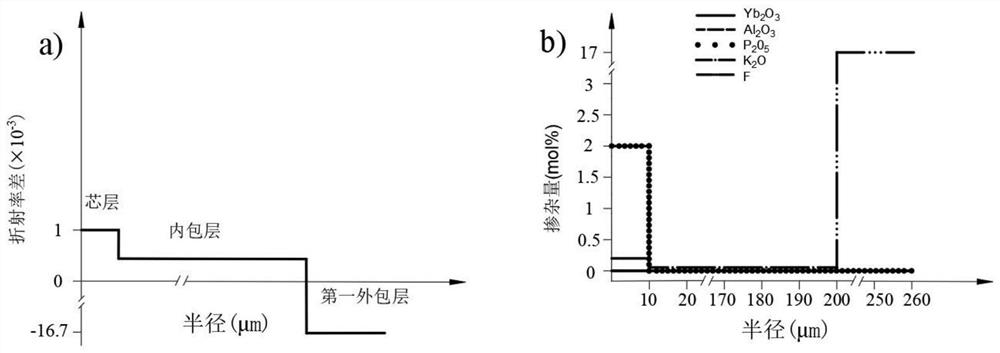

Embodiment 2

[0032] In the triple-clad optical fiber of this embodiment, the radii of the core layer, the inner cladding layer and the outer cladding layer are 10 μm, 200 μm and 260 μm, respectively. The core layer composition of triple-clad fiber is 2Al 2 o 3 +2P 2 o 5 +0.2Yb 2 o 3 , and the rest are quartz (SiO 2 ), the refractive index difference with pure quartz is +1×10 -3 ;Inner cladding composition is 0.025K 2 O, the rest is SiO 2 , the refractive index difference with pure quartz is +0.45×10 -3 ; The outer cladding component is 17F, and the rest is SiO 2 , the refractive index difference with pure quartz is -1.67×10 -2 . Therefore, the numerical aperture of the core layer is 0.04, and the numerical aperture of the inner cladding layer is 0.22.

Embodiment 3

[0034] In the triple-clad optical fiber of this embodiment, the radii of the core layer, the inner cladding layer and the outer cladding layer are 10 μm, 200 μm and 260 μm, respectively. The core layer composition of triple-clad fiber is 2Al 2 o 3 +0.2Yb 2 o 3 +2.8F, the rest are quartz (SiO 2 ), and the refractive index difference with pure quartz is +2.8×10 -3 ;Inner cladding composition is 0.084K 2 O, the rest is SiO 2 , the refractive index difference with pure quartz is +1.56×10 -3 ; The outer cladding component is 14.9F, and the rest is SiO 2 , the refractive index difference with pure quartz is -1.51×10 -2 . Therefore, the numerical aperture of the core layer is 0.06, and the numerical aperture of the inner cladding layer is 0.22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com