Preparation method of high-taste soaking-free whole-grain coarse cereal rice

A technology of miscellaneous grains and rice, which is applied in the field of food processing, can solve the problems of high blood sugar index of products, damage to the integrity of miscellaneous grains, and decrease of active substances, etc., to achieve anti-oxidation and inhibition of α-amylase activity, improve taste value, and reduce hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the preparation method of multigrain rice

[0045] (1) The miscellaneous grains are subjected to high-temperature fluidization treatment to obtain non-foaming miscellaneous grains; the high-temperature fluidization treatment conditions of each miscellaneous grain are: red bean 185°C, mung bean 165°C, black rice 145°C, highland barley rice 165°C, and the fluidization time is 15s , to obtain non-foaming miscellaneous grains.

[0046] (2) Weigh 40 grams of non-soaked red bean, 10 grams of non-soaked mung bean, 10 grams of non-soaked black rice, 10 grams of non-soaked highland barley rice, 10 grams of oat germ rice, 10 grams of tartary buckwheat, blood 10 grams of glutinous rice, a total of 100 grams, add 100 grams of polished rice, mix it evenly, wash it twice, do not soak, add water, the mass ratio of water to miscellaneous grains is 1.9:1, cook at normal pressure for 40 minutes, keep warm for 25 minutes, A total of 65 minutes, you can get multigrain rice. ...

Embodiment 2

[0047] Embodiment 2: Optimization of fluidization treatment conditions

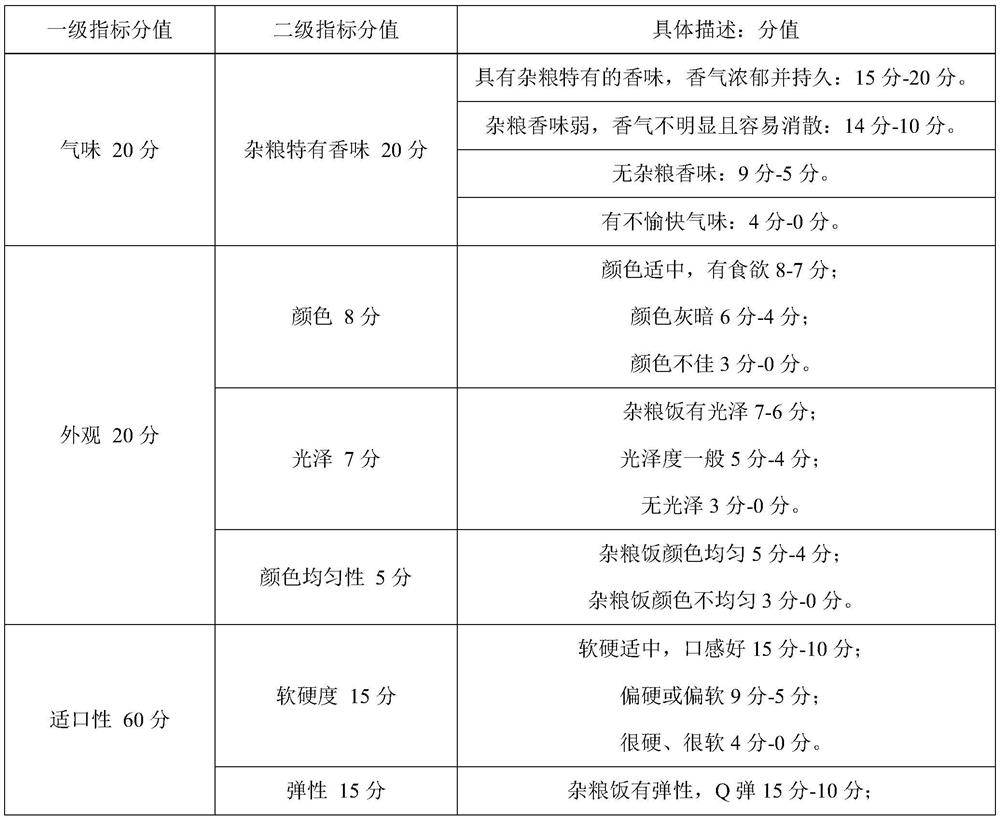

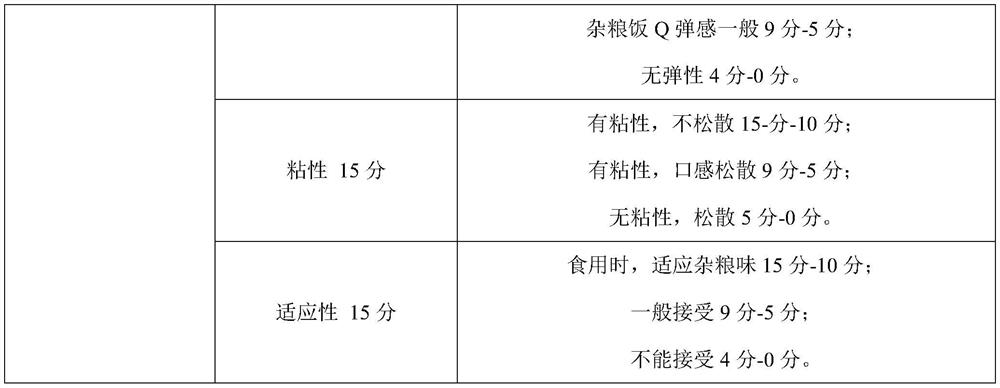

[0048] Selecting non-foaming miscellaneous grain raw materials is an important factor to improve the taste value. It can not only avoid the loss of active substances and aromatic substances in the soaking process of miscellaneous grains before cooking, but also reduce the hardness of miscellaneous grains in rice, ensuring the hardness of miscellaneous grains and rice It can better blend together and improve the taste value of multigrain rice.

[0049] The miscellaneous grains were subjected to high-temperature fluidization treatment to obtain non-foaming miscellaneous grains; the high-temperature fluidization treatment conditions of each miscellaneous grains were: red bean 185°C, mung bean 165°C, black rice 145°C, highland barley rice 165°C, and the fluidization time was 15s. Soak miscellaneous grains, the results are shown in Table 2. The non-foaming miscellaneous grains can be greatly reduced after coo...

Embodiment 3

[0052] Embodiment 3: the selection of raw material

[0053] The proportion of mixed grains is also the key to determine the taste of grains and rice. Different grains have different textures, colors and active ingredients. By referring to the GI values of different grains (see Table 3), select red beans and mung beans , oat germ rice, highland barley rice, tartary buckwheat, black rice and blood glutinous rice are used as raw materials for miscellaneous grain rice. Among them, although the GI value of chickpea is low, it has a clear sense of difference from white rice because of its obvious bean flavor in rice and serious particle expansion after cooking. The non-foaming technology is not suitable for green beans, and the effect of cooking and cooking at the same time cannot be achieved; after adding corn flakes, because the taste of corn is stronger, the taste of multigrain rice is similar to that of corn rice, covering the aroma of other miscellaneous grains; During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com