Water purifying agent and preparation method thereof

A water purifying agent and ultrasonic treatment technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of weak adsorption capacity, inability to treat printing and dyeing wastewater, etc., and achieve good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

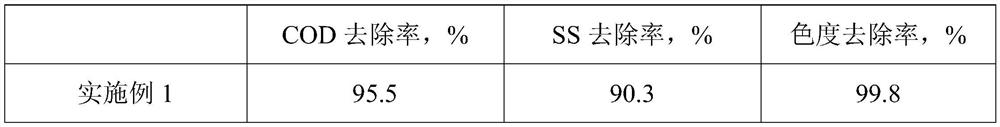

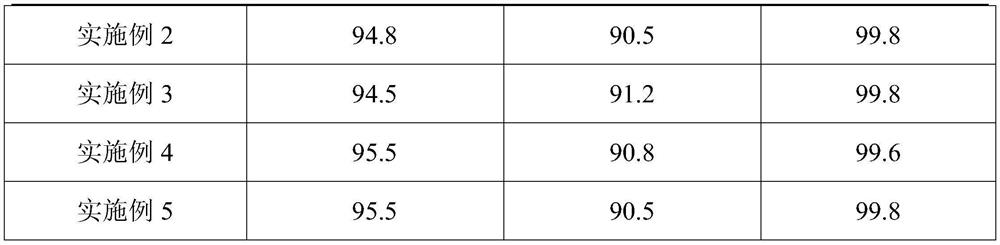

Examples

Embodiment 1

[0025] (1) Mix 10 g of zirconium isopropoxide and 50 ml of isopropanol and sonicate at 200 W for 0.5 h to prepare solution A;

[0026] (2) Mix ethanol and methanol at a volume ratio of 10:0.1 to prepare a mixed solution; add 3g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer to 30ml of the mixed solution In, ultrasonic treatment at 220W for 01h to prepare solution B;

[0027] (3) Slowly add 10ml of solution A to 5ml of solution B. After the addition, ultrasonicate at 200W for 1h; then age at room temperature for 8h, and finally dry; place the obtained solid in a muffle furnace Inside, first raise the temperature to 450°C at a heating rate of 1°C / min, hold for 2 hours, then raise the temperature to 850°C at a heating rate of 8°C / min for 0.5h, and prepare the carrier;

[0028] (4) After crushing and washing the pineapple peel, add it to deionized water and boil for 70 minutes; then cool to room temperature, filter, and collect the filtrate; It i...

Embodiment 2

[0030] (1) Mix 10g of zirconium isopropoxide and 100ml of isopropanol and ultrasonically treat at 300W for 1h to prepare solution A;

[0031] (2) Mix ethanol and methanol at a volume ratio of 10:0.1 to prepare a mixed solution; add 3g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer to 45ml of the mixed solution , sonicated at 200W for 1h to prepare solution B;

[0032] (3) Slowly add 10ml of solution A to 10ml of solution B, after the addition, ultrasonically treat at 350W for 1h; then aging at room temperature for 10h, and finally dry; place the obtained solid in a muffle furnace Inside, first raise the temperature to 500°C at a heating rate of 2°C / min, hold for 2 hours, then raise the temperature to 900°C at a heating rate of 9°C / min for 1 hour, and prepare the carrier;

[0033] (4) After crushing and washing the pineapple peel, add it to deionized water and boil for 80 minutes; then cool to room temperature, filter, and collect the filtrate;...

Embodiment 3

[0035] (1) Mix 10g of zirconium isopropoxide and 70ml of isopropanol and ultrasonically treat it at 40W for 2h to prepare solution A;

[0036] (2) Mix ethanol and methanol at a volume ratio of 10:0.3 to prepare a mixed solution; add 3g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer to 40ml of the mixed solution , sonicated at 400W for 2h to prepare solution B;

[0037] (3) Slowly add 10ml of solution A to 10ml of solution B. After the addition, ultrasonically treat at 300W for 2h; then aging at room temperature for 11h, and finally dry; place the obtained solid in a muffle furnace Inside, first raise the temperature to 500°C at a heating rate of 1°C / min, hold for 3 hours, and then raise the temperature to 900°C at a heating rate of 11°C / min for 0.5h to prepare the carrier;

[0038] (4) After crushing and washing the pineapple peel, add it to deionized water and boil for 70 minutes; then cool to room temperature, filter, and collect the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com