Method for removing welding slags on multi-phase cold expansion type workbench

A workbench and cold-expanding technology, applied in cleaning methods and utensils, chemical instruments and methods, manufacturing tools, etc., can solve problems such as irregular human operations, damage to the workbench, and the impact of re-welding work, etc., to improve the wiping effect , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] see Figure 1-3 , a method for removing welding slag on a multi-phase cold-expanding workbench, comprising the following steps:

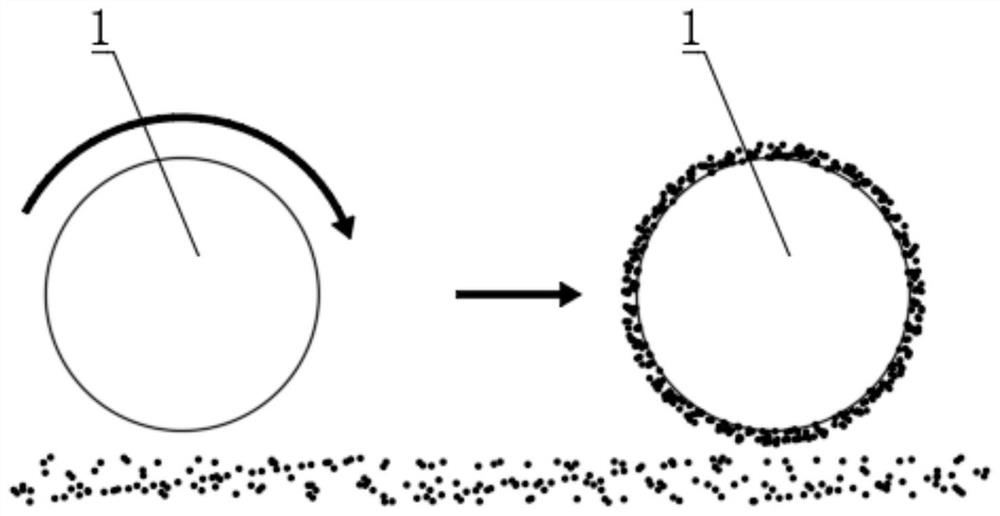

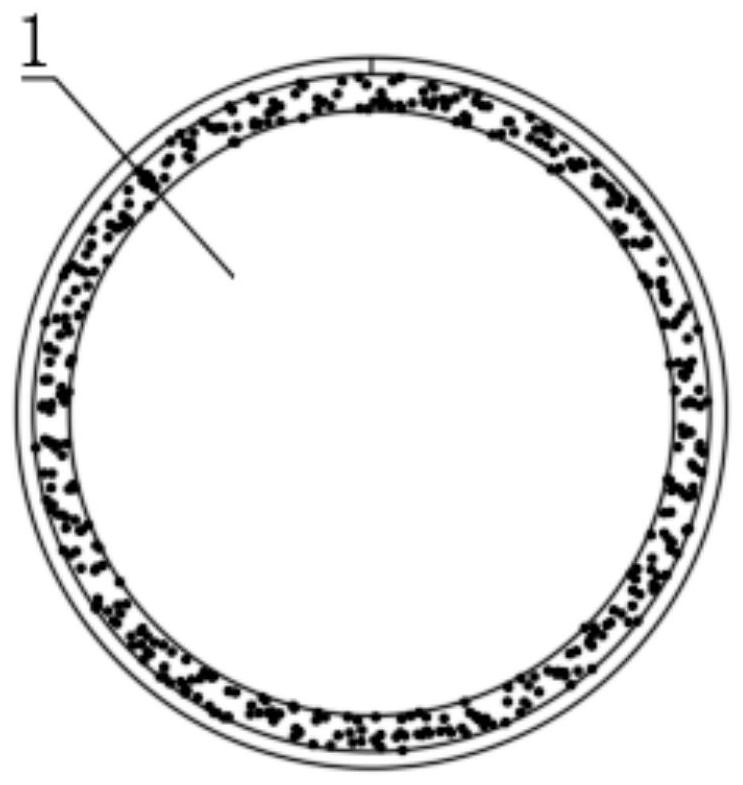

[0045] S1. Place the multiphase deformed ball 1 on the refrigeration powder and roll freely until the surface of the multiphase deformed ball 1 is covered with a layer of refrigerant powder, and put a protective sleeve on the outside to complete the multiphase cold seal ball. preparation;

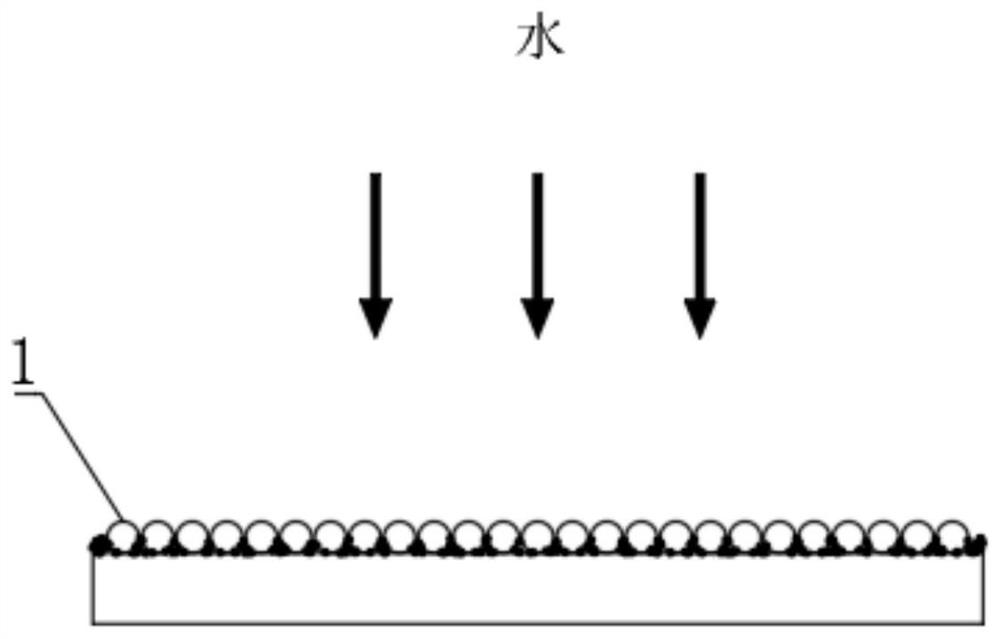

[0046] S2. Place the multi-phase cold sealing ball on the workbench where welding slag needs to be removed, and evenly sprinkle water on the entire workbench surface. With the help of the temperature drop, a layer of ice layer is formed on the workbench surface to complete the welding Cold sealing of workbench;

[0047] S3. With the help of the upper top of the multi-phase deformation ball, separate the ice layer from the workbench, and lift up the welding slag on the workbench, so as to complete the removal of welding slag, and finally simply wipe the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com