Screening and application of high-yield 2-phenylethanol microzyme strain

A phenethyl alcohol and yeast technology, applied in the field of fermentation engineering, can solve the problems of inability to meet industrial production, low 2-phenylethyl alcohol yield and the like, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

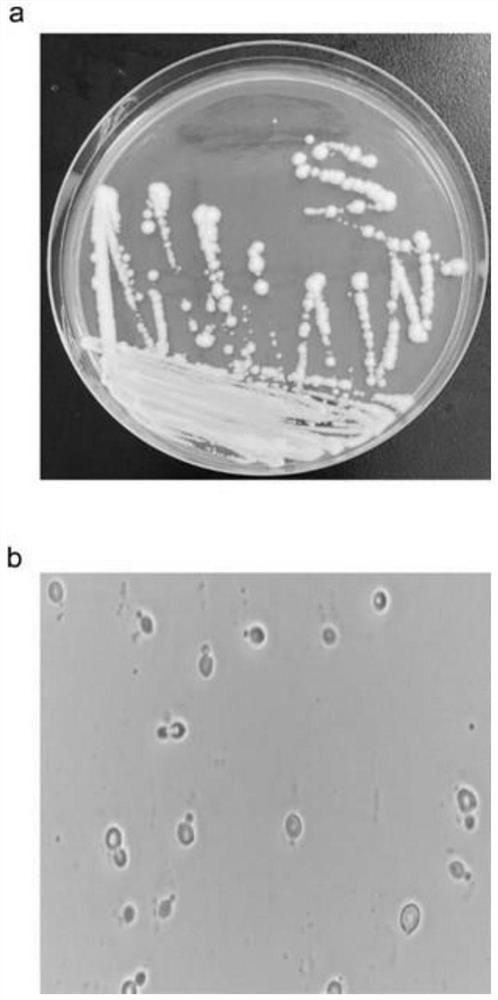

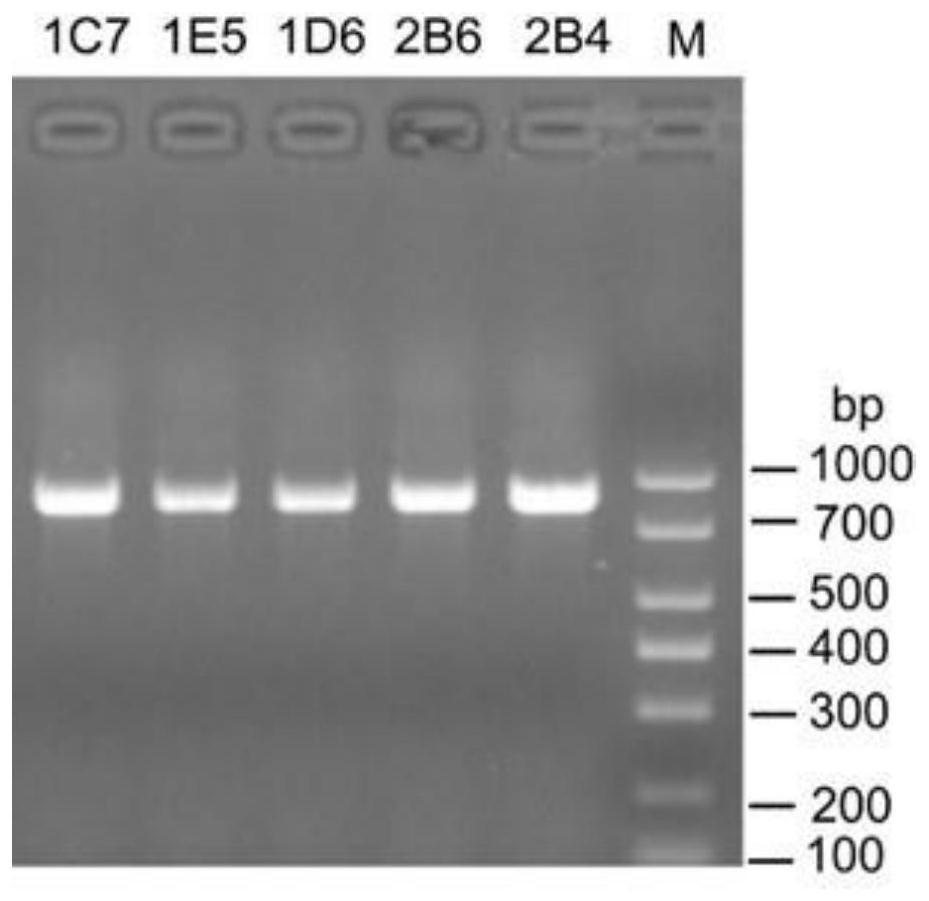

[0059]Example 1: Screening and isolation of strains

[0060](1) Weigh 1g of medicinal koji, add 9mL of sterile water, soak for 15 minutes and then shake well to make a bacterial suspension; under aseptic operating conditions, dilute to 10 with sterile water.-6, 10-5, 10-4, 10-3, 10-2, 10-1Gradient bacterial suspension; take 100μL of each gradient bacterial suspension and spread it on YPD plates, and make three parallel dilutions of each gradient; invert the medium plate in a 30℃ constant temperature incubator for 2 days, and select the protrusions on the surface of the plate. Single colony with milky white, irregular edges and opaque, streak on the YPD plate until a single colony grows, repeat the streak on the plate until each plate grows a single colony (that is, the colony form on each plate Consistent); Pick a single colony from each plate and store it on YPD slant medium.

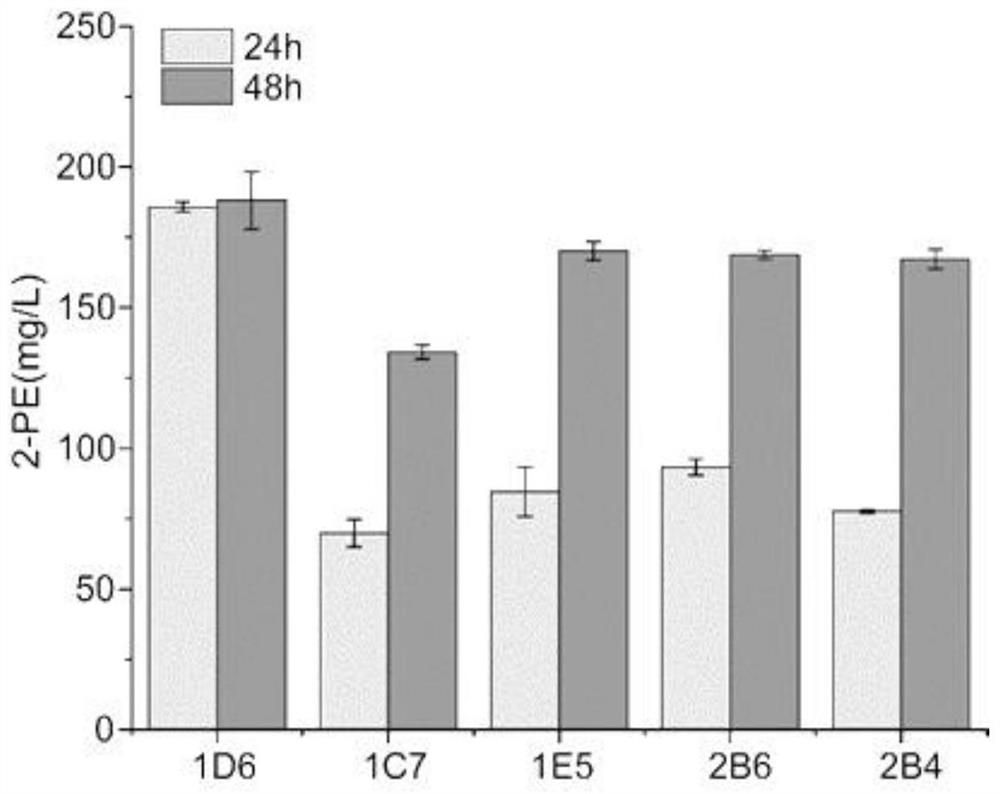

[0061](2) Preliminary screening of strains: Inoculate the strains obtained in step (1) into YPD medium, culture...

Embodiment 2

[0070]Example 2: Production of 2-Phenylethanol by Yeast Shaking Flask Culture

[0071](1) Fermentation culture of strains in SC medium

[0072]The screened abnormal Wickham's yeast 1D6 was activated in YPD liquid medium to the initial OD600The inoculum values of 0.1 and 30mL / 250mL were inoculated into SC medium, and the fermentation broth was taken every 8h and cultured for 56h at 30°C and rotating speed of 220r / min. The fermentation broth was centrifuged at 12000r / min for 10min at 4°C, filtered through a 0.22μm organic filter membrane, and analyzed by HPLC.

[0073]The results showed that after 24 hours of culture, the yield basically stabilized, and the yield of 2-PE was as high as 2274.73mg / L (Figure 5 ).

[0074](2) The effect of glucose concentration in SC medium on the production of 2-phenylethanol

[0075]The specific method is shown in step (1), the difference is that the glucose concentration in the SC medium is replaced, the fermentation is carried out for 48 hours, and the production ...

Embodiment 3

[0084]Example 3: Production of 2-Phenylethanol by Yeast Fermentation Tank Culture

[0085]The abnormal Wickham's yeast 1D6 was cultured at scale and cultured on YPD plates for 2-3 days. Then pick a single colony and inoculate it into a medium containing 100mL / 500ml YPD, culture it at 30°C, 220rpm / min shaker for 24h as seed solution. Both batch and fed-batch fermentation were carried out in a 5L fermentor equipped with 2.5L of fermentation medium (ie, optimized SC medium).

[0086]OD6004.0 is the seed liquid, inoculated into the fermentation medium at an inoculum of 10mL / 100mL, the stirring speed is 400rpm, and the aeration rate is 2.0vvm. Use sterile 4mol / L NaOH solution and 4mol / L HCl solution to control the pH of the fermentation medium to 4.5. All cultures were performed at 30°C. The content of 2-phenylethanol in the fermentation broth was measured every 12 hours, and the results are shown in Table 3. At 24h of fermentation, L-phenylalanine with a final concentration of 5g / L was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com