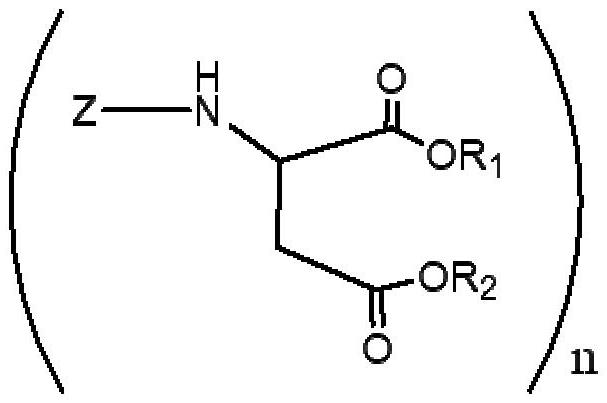

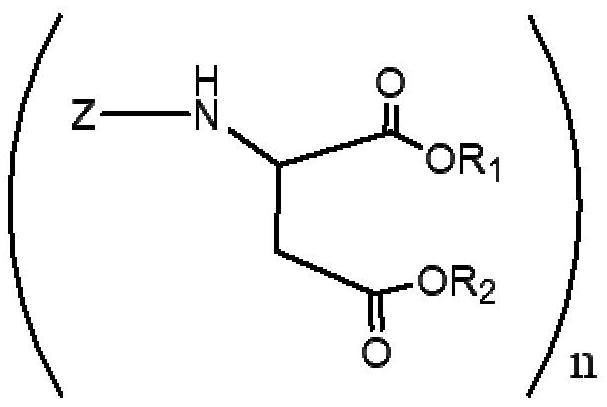

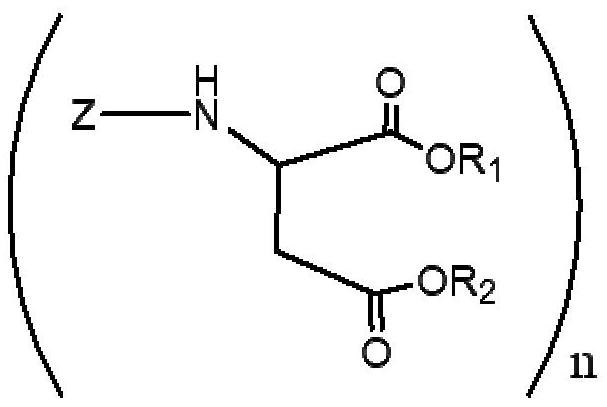

Polyurea compositions from polyaspartic esters and secondary heterocyclic amines derived aspartic esters

A technology of aspartic acid ester and composition, applied in the field of polyurea coating composition, can solve the problems of premature gelation of polyurea coating, application of mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1. Preparation of a polyaspartate / aspartate mixture from diethyl maleate, 4,4'-diaminodicyclohexylmethane (PACM) and piperidine.

[0068] When equipped with N 2 A 2-liter glass reactor with gas inlet tube, thermocouple and addition funnel was charged with 4,4'-diaminodicyclohexylmethane (PACM) (470.72 g, 2.0 moles) and heated to 80°C. Diethyl maleate (688.8 g, 4 moles) was added slowly while maintaining the temperature at 80-85°C. The mixture was kept at this temperature for 6 hours. An oliquot sample analyzed by gas chromatography showed the presence of 5% by weight (0.32 moles) of diethyl fumarate. Piperidine (27.48 g, 0.32 mol) was added and the mixture was allowed to reach ambient temperature. After 3 days, no diethyl fumarate was detected by gas chromatography.

Embodiment 2

[0069] Example 2. Preparation of a polyaspartate / aspartate mixture from diethyl maleate, 4,4'-diaminodicyclohexylmethane (PACM) and pyrrolidine.

[0070] When equipped with N 2 A 2-liter glass reactor with gas inlet tube, thermocouple and addition funnel was charged with 4,4'-diaminodicyclohexylmethane (PACM) (470.72 g, 2.0 moles) and heated to 80°C. Diethyl maleate (688.8 g, 4 moles) was added slowly while maintaining the temperature at 80-85°C. The mixture was kept at this temperature for 6 hours. A sample analyzed by gas chromatography showed the presence of 5% by weight (0.32 moles) of diethyl fumarate. Pyrrolidine (22.90 g, 0.32 mol) was added and the mixture was allowed to reach ambient temperature. After 3 days, no diethyl fumarate was detected by gas chromatography.

Embodiment 3

[0071] Example 3. Preparation of a polyaspartate / aspartate mixture from diethyl maleate, 4,4'-diaminodicyclohexylmethane (PACM) and piperazine.

[0072] When equipped with N 2 A 2-liter glass reactor with gas inlet tube, thermocouple and addition funnel was charged with 4,4'-diaminodicyclohexylmethane (PACM) (470.72 g, 2.0 moles) and heated to 80°C. Diethyl maleate (688.8 g, 4 moles) was added slowly while maintaining the temperature at 80-85°C. The mixture was kept at this temperature for 6 hours. A sample analyzed by gas chromatography showed the presence of 5% by weight (0.32 moles) of diethyl fumarate. Piperazine (27.69 g, 0.32 mol) was added and the mixture was allowed to reach ambient temperature. After 7 days, no diethyl fumarate was detected by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com