A high-efficiency plugging film-forming shield mud material for emergency rescue

A technology of film formation and shield tunneling, applied in the direction of landfill technology, etc., can solve problems such as plugging failure, engineering quality and safety accidents, and accurately describe the status of the stratum, so as to achieve the effect of ensuring stability and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of macromolecule wrapping material, it is made by following steps:

[0039] Step 1. Take quantitative biogel and add it to a 100ml Erlenmeyer flask. After adding N,N-dimethylformamide into the Erlenmeyer flask at a volume ratio of 1:20, place the Erlenmeyer flask at a constant temperature In a water bath environment, heat up and stir to completely dissolve the bio-glue;

[0040] Step 2, adding solid sodium hydroxide to the Erlenmeyer flask, adjusting the pH value of the mixed solution to 8, then heating and stirring for 30 minutes;

[0041] Step 3. After fully dissolving the modifier in N,N-dimethylformamide, drop the dissolved modifier into the Erlenmeyer flask using a constant pressure dropping funnel, and react at 65°C for 24h ;

[0042]Step 4, adding excess isopropanol to the solution after the reaction, and drying the precipitate after 1 hour of precipitation for subsequent use;

[0043] Step 5, fully dissolve the precipitate in distilled water, add calci...

Embodiment 2

[0048] A shield mud, calculated by weight percentage, comprises: 10% of a film-forming shield mud material for high-efficiency plugging and emergency rescue, and 90% of water.

[0049] The above-mentioned shield mud is prepared by the following steps: take a quantitative amount of the high-efficiency plugging film-forming shield mud material for emergency emergency use, add water and the high-efficiency plugging film-forming shield material for emergency emergency use in a container in proportion The mud material is stirred continuously to make it fully dissolved, and it is allowed to stand for 2 hours.

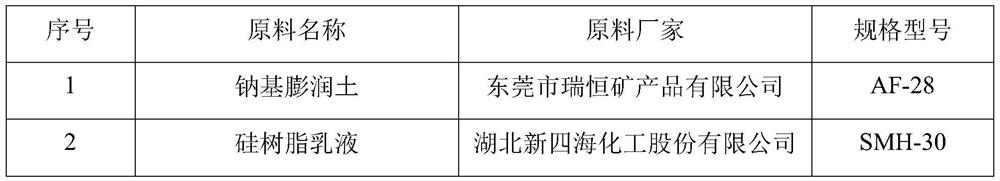

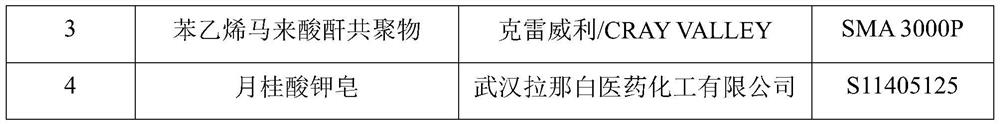

[0050] The high-efficiency plugging film-forming shield mud material for emergency rescue includes, by weight percentage: 72% of sodium bentonite, 15% of polymer wrapping material, 2% of styrene-maleic anhydride copolymer, and 10% of silicone resin emulsion. %, potassium laurate soap 1%.

[0051] The polymer wrapping material mentioned above is the polymer wrapping material ...

Embodiment 3

[0053] A shield mud, calculated by weight percentage, comprises: 10% of a film-forming shield mud material for high-efficiency plugging and emergency rescue, and 90% of water.

[0054] The preparation method of the above-mentioned shield mud is the same as that in Example 2.

[0055] The high-efficiency plugging film-forming shield mud material for emergency rescue includes, by weight percentage: 74% of sodium bentonite, 15% of polymer wrapping material, 1% of styrene-maleic anhydride copolymer, and 8% of silicone resin emulsion %, potassium laurate soap 2%.

[0056] The polymer wrapping material mentioned above is the polymer wrapping material prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com