A kind of electromagnetic shielding concrete and preparation method thereof

An electromagnetic shielding and concrete technology, which is applied in the field of concrete materials, can solve problems such as poor compatibility, uneven distribution of graphite and coke, and inconvenient concrete electromagnetic shielding function, so as to improve the electromagnetic shielding effect, improve electromagnetic shielding performance, and improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

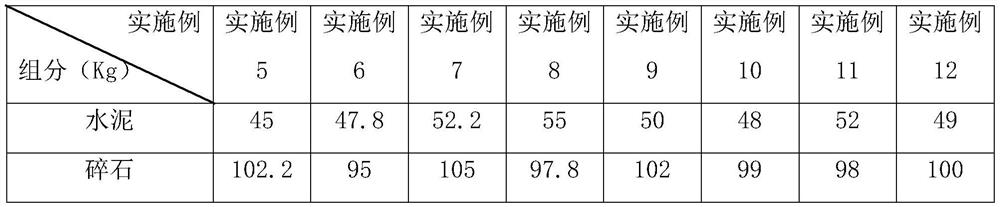

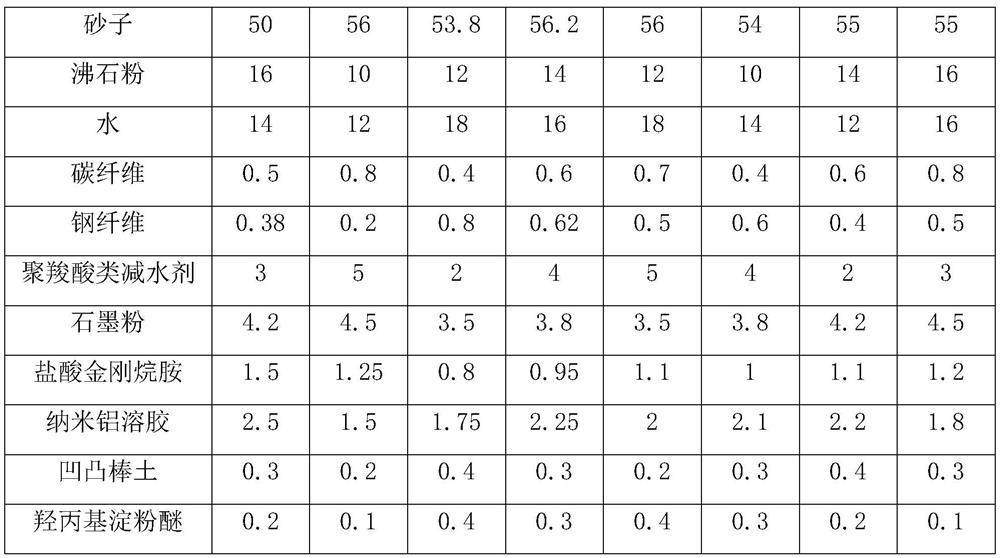

Examples

Embodiment 1

[0038] Embodiment 1: a kind of electromagnetic shielding concrete preparation method, comprises the following steps:

[0039]S1 Additive preparation: Weigh 0.6kg of carbon fiber, add 0.5kg of steel fiber, 4kg of polycarboxylate water reducer, 0.3kg of attapulgite and 0.2kg of hydroxypropyl starch ether, and mix well to prepare the additive.

[0040] Preparation of S2 conditioner: sieve graphite powder with a sieve with a pore size of 50 μm, and pulverize particles with a particle size greater than 50 μm with a pulverizer until the particle size is not greater than 50 μm, and select graphite powder with a particle size not greater than 50 μm. Weigh 4 kg of graphite powder with a particle size not greater than 50 μm, add 1.1 kg of amantadine hydrochloride and 2 kg of aluminum sol (Hangzhou Jiupeng New Material Co., Ltd., model CY-L10A, median particle size D50 is 10 nm, solid content 20 %, the median particle size is the particle size corresponding to when the cumulative particl...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that the specifications of the aluminum sol used in Example 2 are different. Example 2 uses an aluminum sol with a median particle size of 30 nm and a solid content of 15%. Others are consistent with Example 1.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is that attapulgite is not added in embodiment 3, and the others are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com