Porous organic framework material and preparation method thereof, and application in selective separation of perrhenate radicals

A technology of organic skeleton and perrhenate, applied in organic anion exchangers, organic cation exchangers, separation methods, etc., can solve problems such as unsatisfactory selective separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

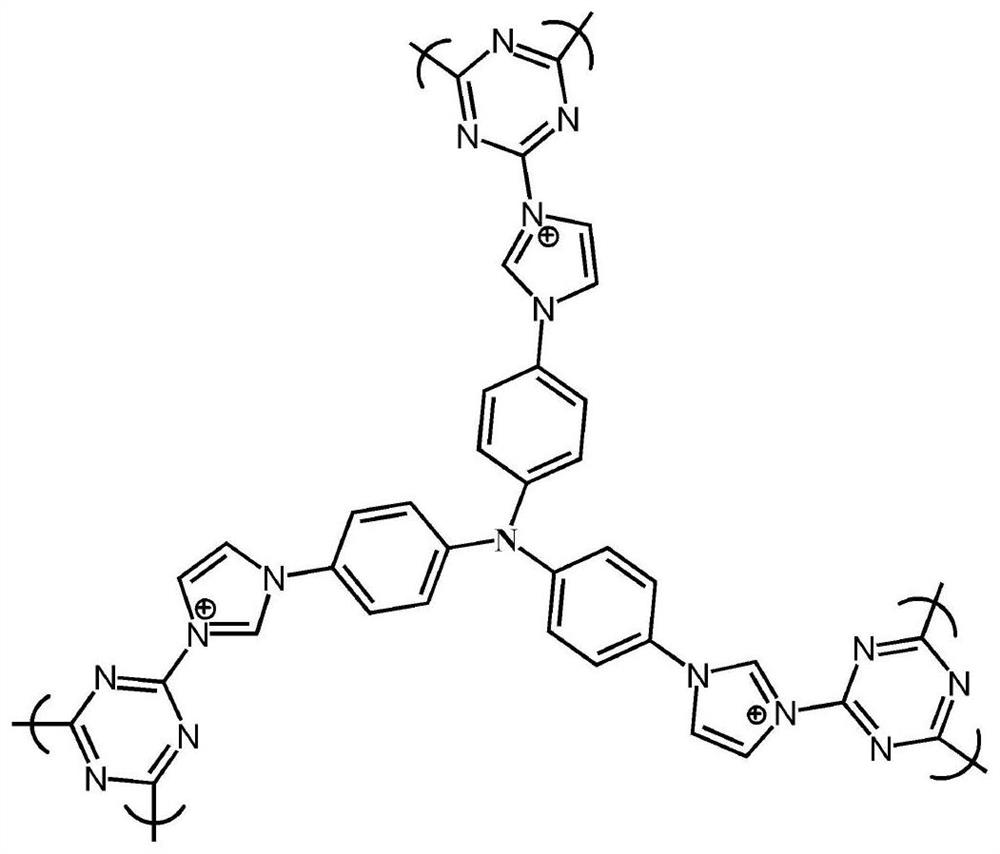

[0024]The present invention provides a method for preparing porous organic framework material, which includes the following steps:

[0025]Tris(4-imidazolylphenyl)amine, cyanuric chloride and an organic solvent are mixed to carry out a quaternization reaction to obtain a porous organic framework material.

[0026]In the present invention, the ratio of the amounts of the tris(4-imidazolylphenyl)amine and cyanuric chloride is preferably (0.6 to 1.2): (0.4 to 0.8), more preferably 1:1. In the present invention, the ratio of the amount of tris(4-imidazolylphenyl)amine and cyanuric chloride within the above-mentioned range enables sufficient quaternization reaction.

[0027]In the present invention, the organic solvent is preferably N,N'-dimethylformamide, N,N'-dimethylacetamide or N-methylpyrrolidone. In the present invention, the amount of the organic solvent is not particularly limited, as long as the raw material can be dissolved.

[0028]In the present invention, the operation of mixing the tri...

Embodiment 1

[0046]Weigh 0.355 g of tris(4-imidazolylphenyl)amine and dissolve it in 20mL of N,N'-dimethylformamide solvent to obtain the first solution; weigh 0.148 g of cyanuric chloride and dissolve in 20mL of N,N'-dimethylformamide The second solution is obtained in the base formamide solvent; the ratio of the amount of the tris(4-imidazolylphenyl)amine and cyanuric chloride is 1:1; then the above two solutions are mixed at 100°C Oil bath reaction for 24h, add 0.0016mol benzyl bromide, the ratio of the amount of the benzyl bromide to the tris(4-imidazolylphenyl)amine is 1:2, continue the oil bath reaction at 80°C for 24h ; And then separately with N,N'-dimethylformamide, acetonitrile and ether to wash the product obtained by the reaction, 60 ℃ vacuum drying for 12h, the yellow powder is a porous organic framework material, the yield is 60%.

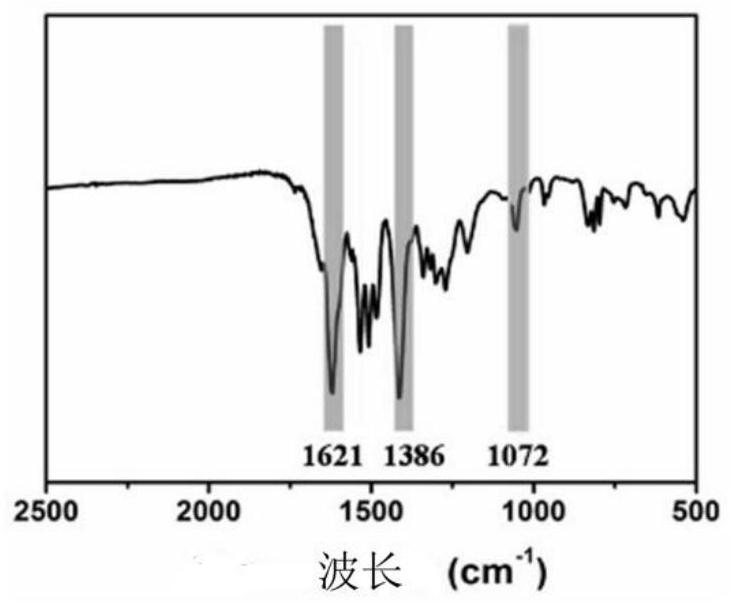

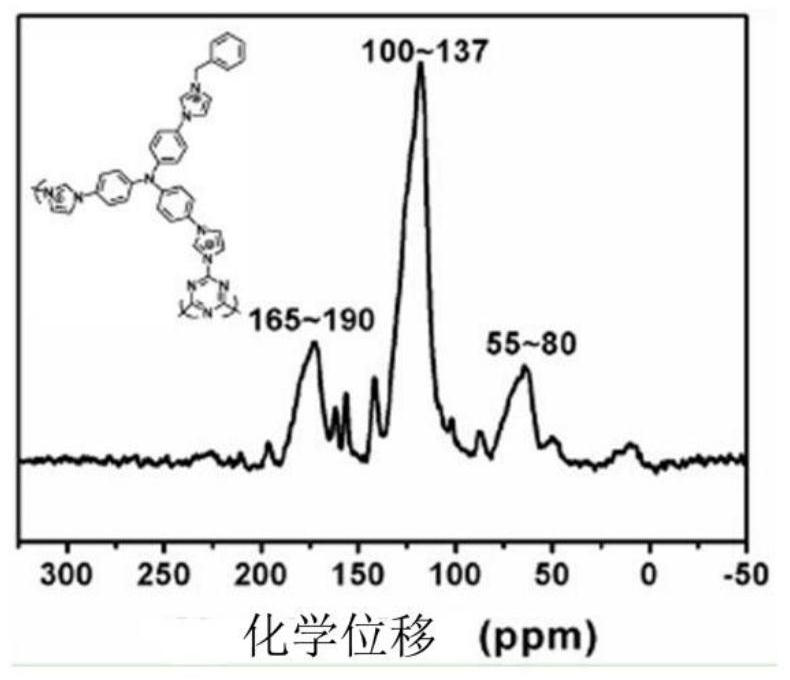

[0047]The red light spectrum test is performed on the porous organic framework material prepared in this embodiment, such asfigure 2 As shown,figure 2 Is ...

Embodiment 2

[0051]Weigh 0.355 g of tris(4-imidazolylphenyl)amine and dissolve it in 20mL of N,N'-dimethylformamide solvent to obtain the first solution; weigh 0.148 g of cyanuric chloride and dissolve in 20mL of N,N'-dimethylformamide The second solution is obtained in the base formamide solvent; the ratio of the amount of the tris(4-imidazolylphenyl)amine and cyanuric chloride is 1:1; then the above two solutions are mixed at 100°C Oil bath reaction for 24h, add 0.0016mol benzyl bromide, the ratio of the amount of the benzyl bromide to the tris(4-imidazolylphenyl)amine is 1:2, continue the oil bath reaction at 80°C for 24h ; The product obtained by the reaction was washed with N,N'-dimethylformamide, acetonitrile and ether, and dried in vacuum at 60°C for 12h to obtain a yellow powder that is a porous organic framework material with a yield of 52%.

[0052]The red light spectrum test was performed on the porous organic framework material prepared in this embodiment, and it was proved that the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com