Preparation method of phase change ink

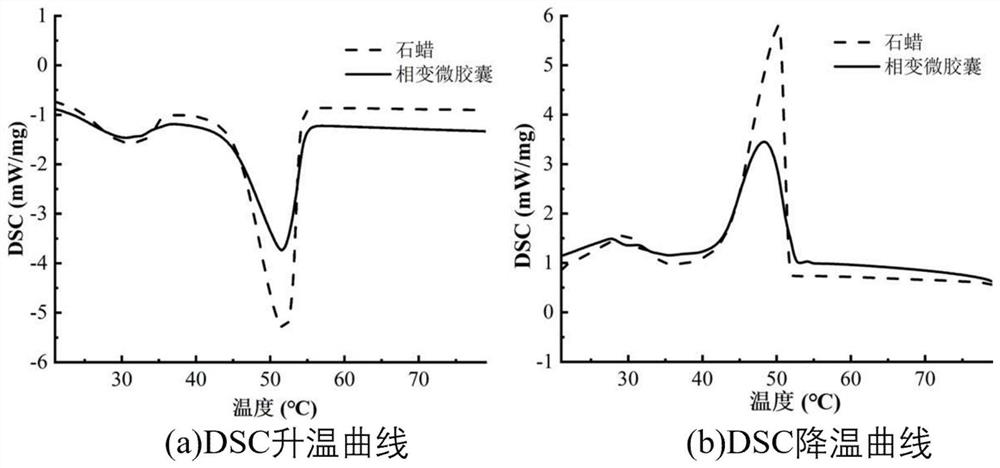

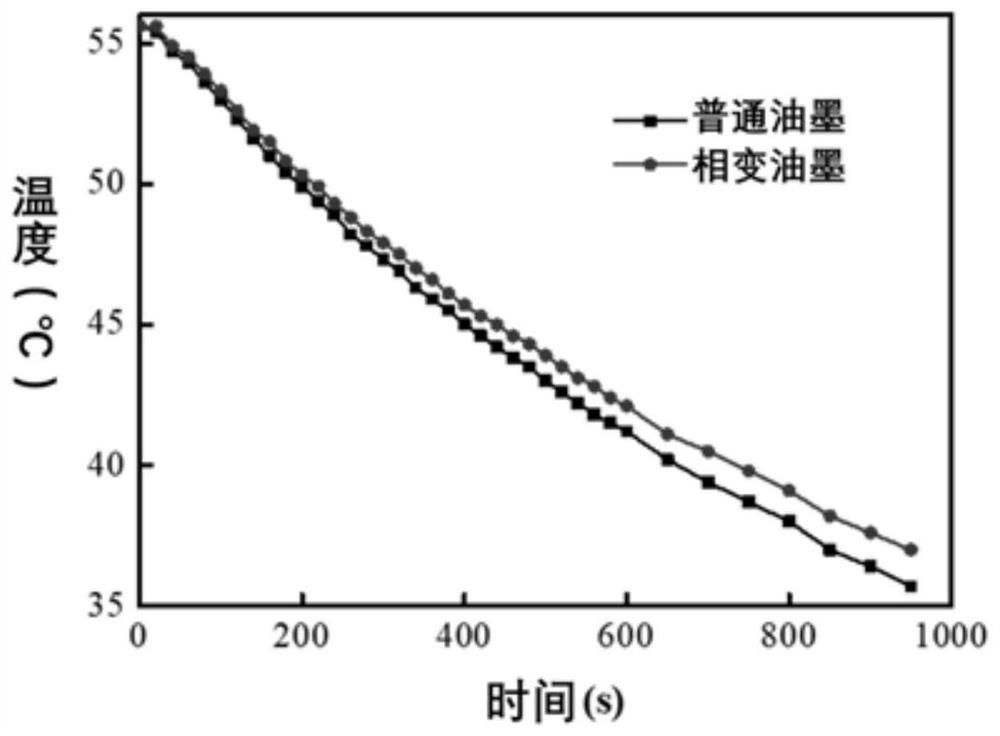

A technology of phase change ink and phase change microcapsules, applied in the directions of ink, chemical instruments and methods, heat exchange materials, etc., can solve the problems of weak adhesion, poor temperature control ability of phase change ink, etc., and save energy. , Improve the effect of heat preservation and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

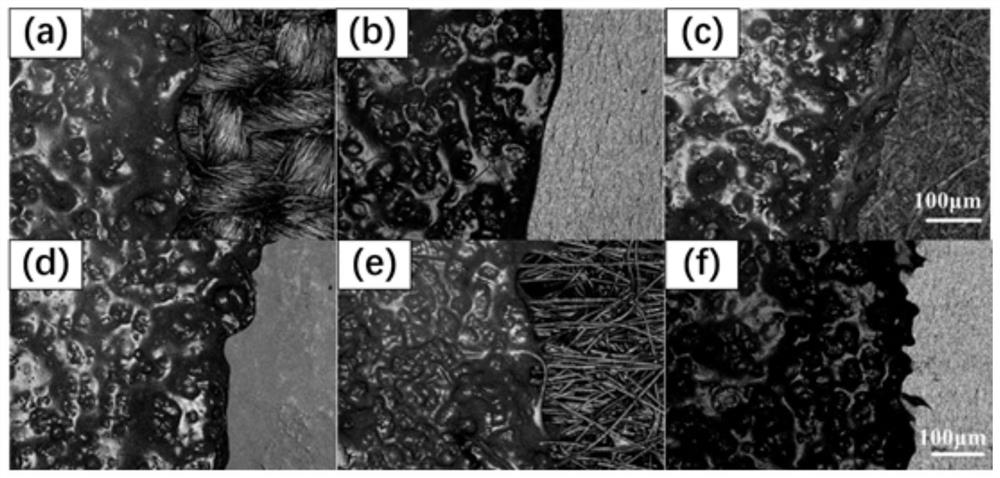

Examples

Embodiment 1

[0029] (1) Preparation of phase change microcapsules:

[0030] (1-1) Preparation of styrene maleic anhydride copolymer sodium salt (SMAHNa) emulsifier: 15g of SMA powder, 4.2g of sodium hydroxide and 130.6g of deionized water were added to a three-necked round-bottomed flask and placed in a constant temperature water bath Stir mechanically at 50° C. for 5 h to obtain a styrene-maleic anhydride copolymer sodium salt emulsifier (SMAHNa emulsifier) with a mass fraction of 10%, which is put in a beaker for subsequent use;

[0031] (1-2) Preparation of core material: Add 10g of SMAHNa emulsifier, 12g of n-octadecane and 100ml of deionized water into another three-neck round bottom flask, melt it in a water bath at a temperature of 70°C, and then rotate at 900rpm Emulsify for 2 hours under the condition of / min to obtain a stable O / W emulsion, keep the O / W emulsion in a stirring state for use;

[0032] (1-3) Preparation of resin aqueous solution: put 9g of gelatin in room tempera...

Embodiment 2

[0036] (1) Preparation of phase change microcapsules:

[0037] (1-1) Preparation of styrene-maleic anhydride copolymer sodium salt (SMAHNa) emulsifier: 18g of SMA powder, 5g of sodium hydroxide and 133g of deionized water were added to a three-necked round-bottomed flask and placed in a constant temperature water bath at 45°C Under mechanical stirring for 4h, the styrene-maleic anhydride copolymer sodium salt emulsifier (SMAHNa emulsifier) with a mass fraction of 10% was obtained, which was put in a beaker for subsequent use;

[0038] (1-2) Preparation of core material: Add 13g of SMAHNa emulsifier, 10g of liquid paraffin and 100ml of deionized water into another three-neck round bottom flask, melt it in a water bath at a temperature of 60°C, and then rotate at 500rpm / min Under emulsification for 2.2 hours, a stable O / W emulsion was obtained, and the O / W emulsion was kept under stirring for use;

[0039] (1-3) Preparation of resin aqueous solution: put 8.4g of gelatin in ro...

Embodiment 3

[0043] (1) Preparation of phase change microcapsules:

[0044] (1-1) Preparation of styrene-maleic anhydride copolymer sodium salt (SMAHNa) emulsifier: 14g of SMA powder, 4g of sodium hydroxide and 128g of deionized water were added to a three-neck round-bottomed flask and placed in a constant temperature water bath at 55°C Under mechanical stirring for 5.5 hours, the styrene-maleic anhydride copolymer sodium salt emulsifier with a mass fraction of 10% was obtained, which was put in a beaker for subsequent use;

[0045] (1-2) Preparation of core material: Add 9g of SMAHNa emulsifier, 11g of n-eicosane and 100ml of deionized water into another three-necked round-bottomed flask, melt at a water bath temperature of 80°C, and then rotate at 550rpm / Emulsify for 2.2 hours under the condition of min to obtain a stable O / W emulsion, keep the O / W emulsion in a stirring state for use;

[0046] (1-3) Preparation of resin aqueous solution: put 10g of gelatin in normal temperature water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com