Preparation method of cannabis sativa protein zymolyte craft beer

A technology of proteolysis and hemp, which is applied in the field of fermented food, can solve problems such as retention and low competitiveness, and achieve the effect of white foam, promotion of development, and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

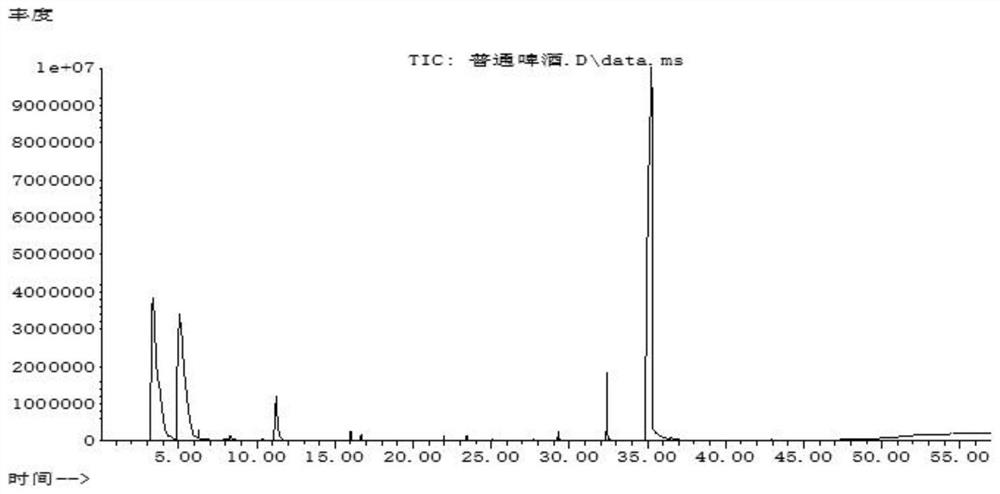

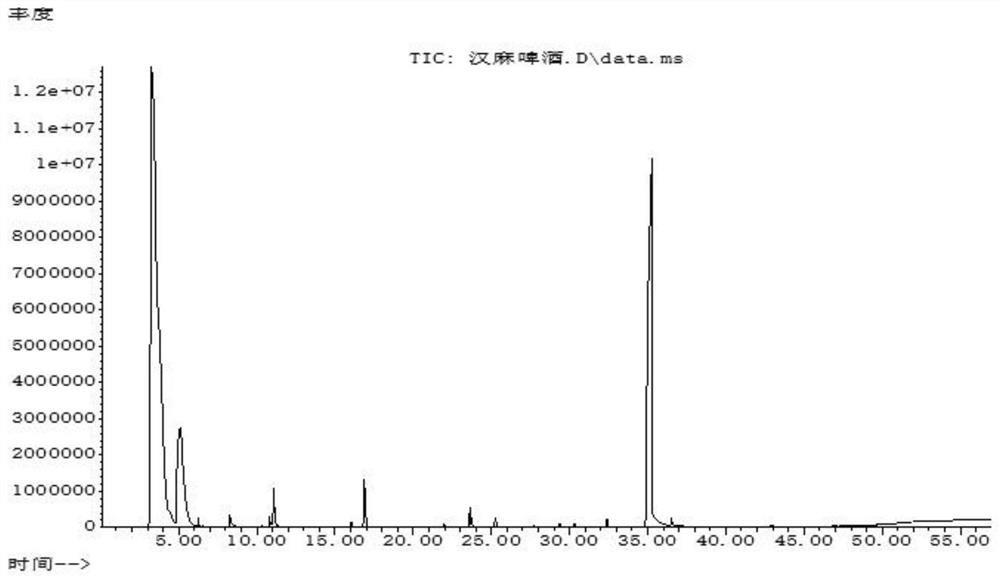

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: what this embodiment records is a kind of preparation method of hemp protein enzymatic hydrolyzate craft beer, described method is:

[0026] (1) Mix the hemp seed meal and distilled water according to the mass ratio of 1:10 to prepare the hemp seed meal mixture;

[0027] (2) Adjust the pH value of the hemp seed meal mixture to 5-6, add 0.5-0.8% papain, 2.5-3.5% neutral protease, and enzymolysis time 1-2 hours to obtain enzymatic hydrolysis solution; the amount of papain added 0.5-0.8% means that the quality of hemp seed meal is 100, then add 0.5-0.8 papain, 2.5-3.5% is the same;

[0028] (3) After centrifuging the enzymatic hydrolyzate in (2), take the supernatant, filter through a 3kd ultrafiltration membrane, and collect the hemp protein hydrolyzate <3kd;

[0029] (4) subjecting the hemp protein enzymatic hydrolyzate in (3) to vacuum low-temperature freeze-drying to obtain the hemp protein enzymatic hydrolyzate freeze-dried powder;

[0030] ...

specific Embodiment approach 2

[0036] Embodiment 2: In the method for preparing craft beer from hemp protein hydrolyzate described in Embodiment 1, in (4), the temperature of the low-temperature freeze-drying is -30-30° C., and the time is 24 hours.

specific Embodiment approach 3

[0037] Specific embodiment three: the preparation method of a kind of hemp protein enzymatic hydrolyzate craft beer described in specific embodiment one, in (4), the vacuum degree<10Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com