Kiwi fruit beer and preparation method thereof

A technology of kiwi fruit and fruit beer, which is applied in the field of kiwi fruit beer and its preparation, which can solve the problems of discounted nutritional value, unstable beer, and easy precipitation, etc., and achieve the effects of improving quality, preserving flavor, taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

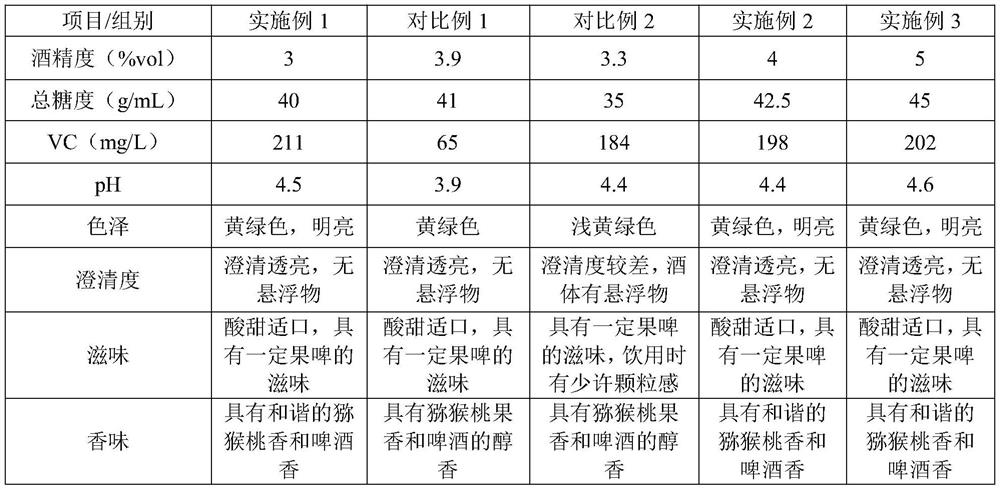

Examples

Embodiment 1

[0046] A preparation method of kiwi fruit beer, comprising the following steps:

[0047] S1. Prepare 3L of kiwi fruit juice with a sugar content of 225g / L, add 150mg of potassium metabisulfite to obtain SO 2 A mixed solution with a content of 25mg / L;

[0048] S2. Inoculate R-HST type Saccharomyces cerevisiae into the mixed solution, the inoculum amount is 300mg / L, carry out temperature-controlled fermentation at 15°C, intermittently circulate or stir during the period, the frequency is 2 times / d (1 time each in the morning and evening), After 14 days, measure its sugar content to be 0g / L, stop circulation or stirring, and obtain fermented liquid;

[0049] S3. The fermented liquid is filled with water and sealed, and after standing for 7 days, the wine lees is separated to obtain SO 2 Clarified liquor with a content of 25mg / L;

[0050] S4. aging the clarified wine liquid at 2°C for 150 days to obtain fruit wine liquid;

[0051] S5. Add 1g / L bentonite to the fruit wine liqui...

Embodiment 2

[0056] A preparation method of kiwi fruit beer, comprising the following steps:

[0057] S1. modulation obtains the kiwi fruit juice that 2.5L sugar content is 240g / L, adds 112.5mg potassium metabisulfite, obtains SO Content is the mixed liquor of 22.5mg / L;

[0058] S2. Inoculate R-HST type Saccharomyces cerevisiae into the mixed solution, the inoculum amount is 300mg / L, carry out temperature-controlled fermentation at 20°C, intermittently circulate or stir during the period, the frequency is 2 times / d (1 time each in the morning and evening), After 10 days, measure its sugar content to be 0.5g / L, stop circulation or stirring, and obtain fermented liquid;

[0059] S3. The fermented liquid is filled with water and sealed, and after standing for 9 days, the wine lees is separated to obtain SO 2 Clarified liquor with a content of 22.5mg / L;

[0060] S4. aging the clarified wine at 4°C for 90 days to obtain fruit wine;

[0061] S5. Add 1g / L bentonite to the fruit wine liquid and...

Embodiment 3

[0066] A preparation method of kiwi fruit beer, comprising the following steps:

[0067] S1. Prepare 2L of kiwi fruit juice with a sugar content of 260g / L, add 80mg of potassium metabisulfite to obtain SO 2 A mixture with a content of 20mg / L;

[0068] S2. Inoculate R-HST type Saccharomyces cerevisiae into the mixed solution, the inoculum amount is 300mg / L, carry out temperature-controlled fermentation at 25°C, intermittently circulate or stir during the period, the frequency is 2 times / d (1 time each in the morning and evening), After 12 days, measure its sugar content to be 1g / L, stop circulation or stirring, and obtain fermented liquid;

[0069] S3. The fermented liquid is filled with water and sealed, and after standing for 8 days, the wine lees is separated to obtain SO 2 Clarified liquor with a content of 20mg / L;

[0070] S4. aging the clarified wine liquid at 3°C for 120 days to obtain fruit wine liquid;

[0071] S5. Add 1g / L bentonite to the fruit wine liquid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com