Efficient environment-friendly coal-fired power generation device

A power generation device, an environment-friendly technology, applied in the field of high-efficiency and environment-friendly coal-fired power generation devices, can solve problems such as insufficient fuel combustion, sulfide, nitride and dust pollutants that have not been effectively resolved, and the formation of dust pollutants. Achieve the effect of small volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

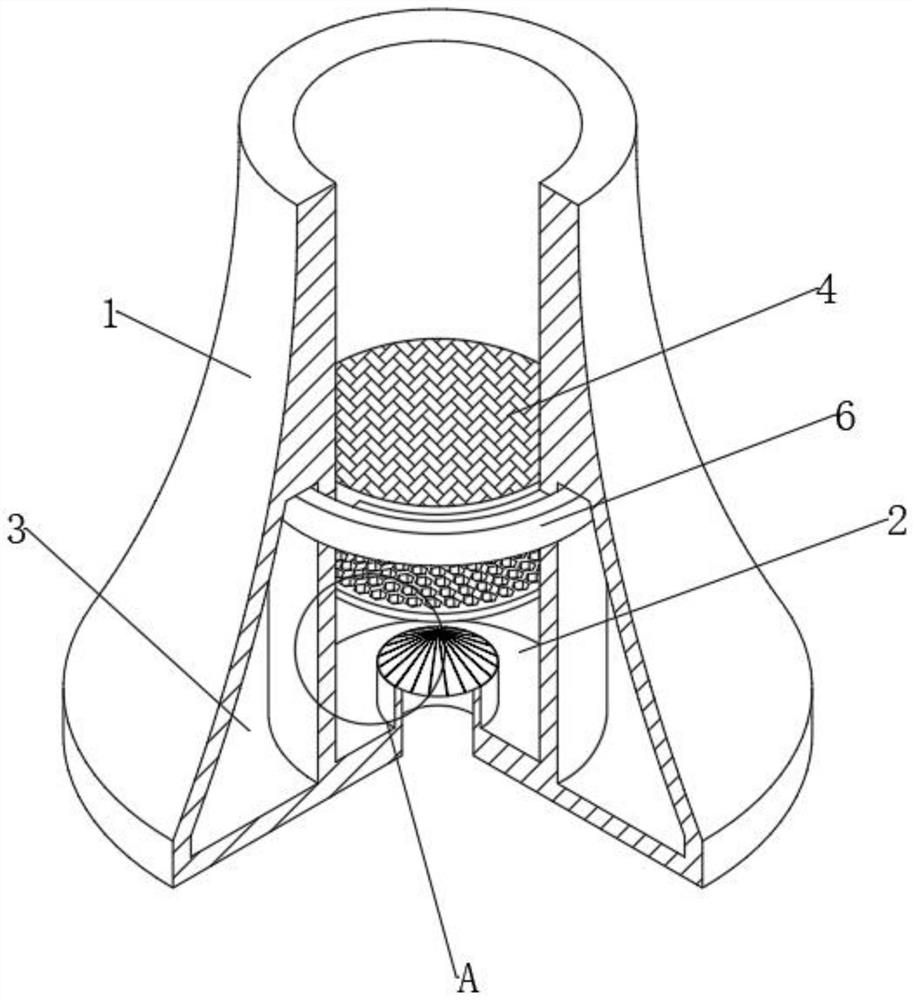

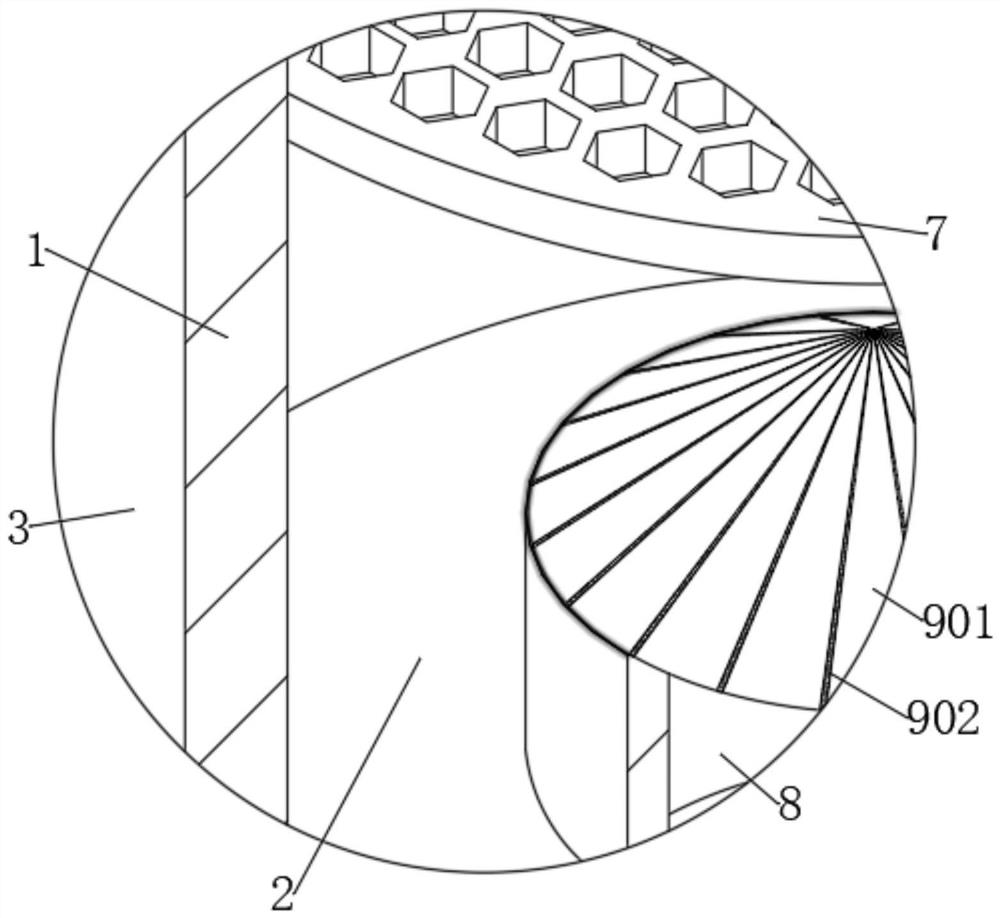

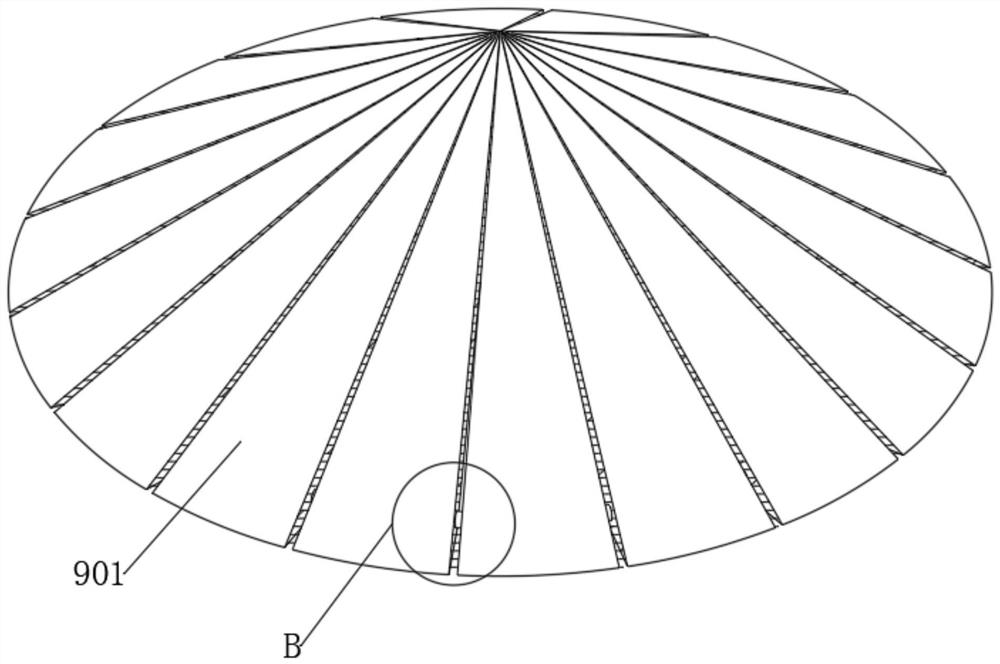

[0036] see Figure 1-6 , a high-efficiency and environment-friendly coal-fired power generation device, comprising a main body 1 of the coal-fired power generation device and a chain fuel, the main body 1 of the coal-fired power generation device is provided with a dustproof plate 4 matching itself, and the dustproof plate 4 includes a plate body 401 , a plurality of capillary pores 402 are drilled in the plate body 401, and the plurality of capillary micropores 402 are connected to each other to form a flue gas channel. The flue gas channel completely penetrates the plate body 401 and connects the coal combustion chamber 2 and the exhaust gas outlet 10. The dustproof plate 4 Divide the internal space of the main body 1 of the coal-fired power generation device into two parts: the coal-fired chamber 2 and the exhaust gas outlet 10, and the waste gas outlet 10 is located on the upper side of the coal-fired chamber 2, and a steam chamber 3 is excavated in the main body 1 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com