Automatic dosing control system and method suitable for electric furnace water system

A control system and automatic dosing technology, applied in the direction of non-electric variable control, water treatment parameter control, multiple fluid ratio control, etc., can solve the problem of inability to accurately grasp the amount of water or dosing, and achieve convenient maintenance, Small water consumption and capacity maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

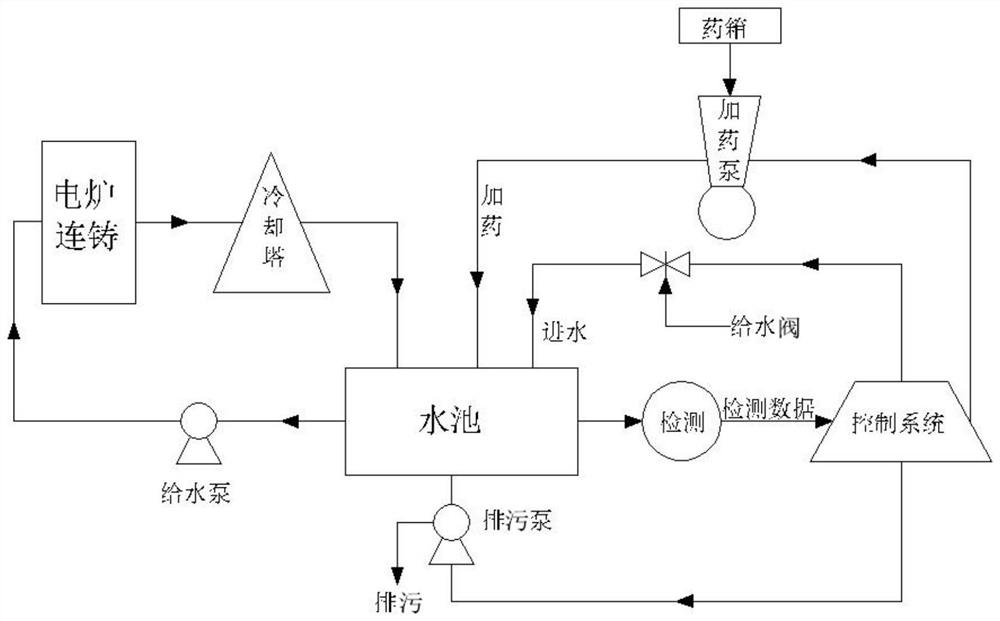

[0018] Such as figure 1 As shown, an automatic dosing control system suitable for the electric furnace water system, including a pool, a dosing pump, a sewage pump, a water supply valve, a control system and an index detection system. connection, the dosing pump, water supply pump, and sewage pump are all connected to the control system signal; Under the control of the system, a certain amount of liquid medicine is added to the pool; the feed pump provides cooling water to the electric furnace or continuous casting through the pipeline, and the cooling water of the electric furnace or continuous casting also flows through the cooling tower and finally flows back to the pool; the sewage pump is connected to the dirt collection device , under the control of the control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com