Scatter coating type oil-containing sediment treatment method

A treatment method and coating technology, applied in dehydration/drying/concentrated sludge treatment, mining wastewater treatment, petroleum industry, etc., can solve problems such as low efficiency, waste of water resources, waste of resources, etc., to improve treatment efficiency, The effect of avoiding mutual interference and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

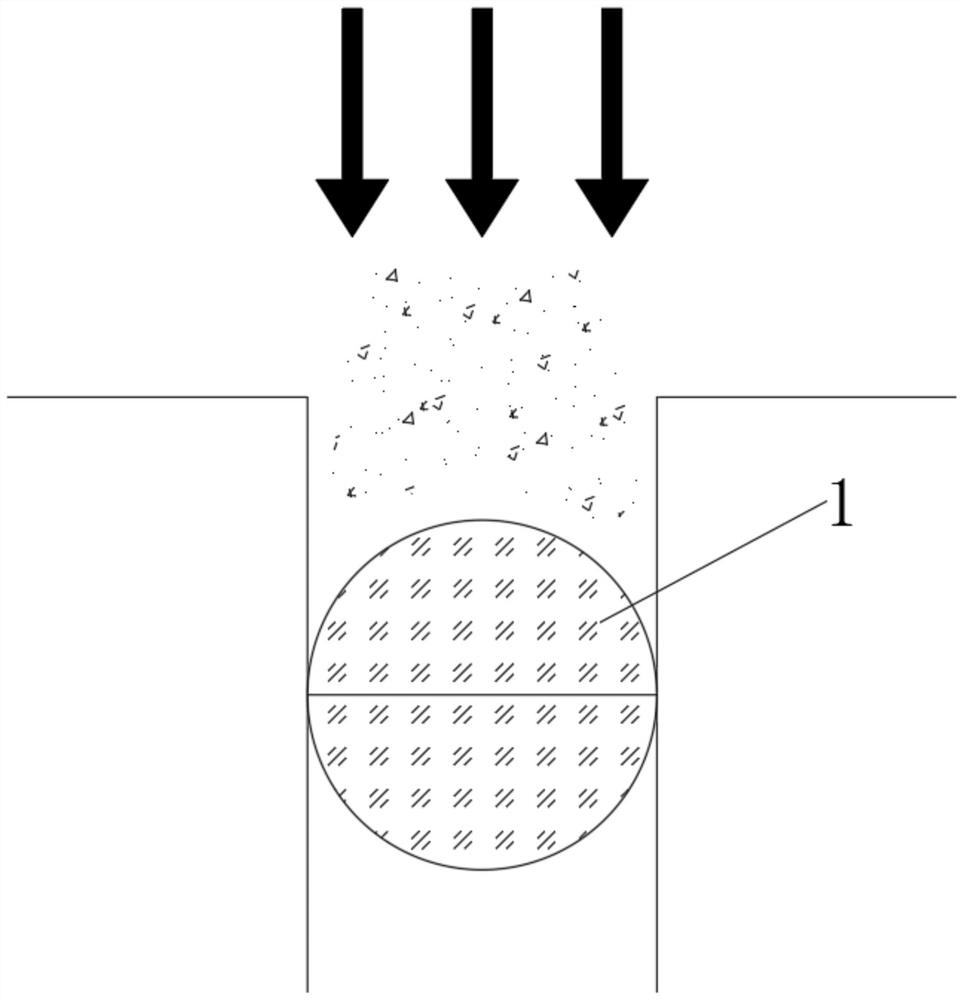

[0047] see figure 1 , a kind of scatter coating type oily sediment processing method, comprises the following steps:

[0048] S1. Disperse and pulverize the oily sediment to be treated, then sieve and disperse evenly, and start oil absorption treatment;

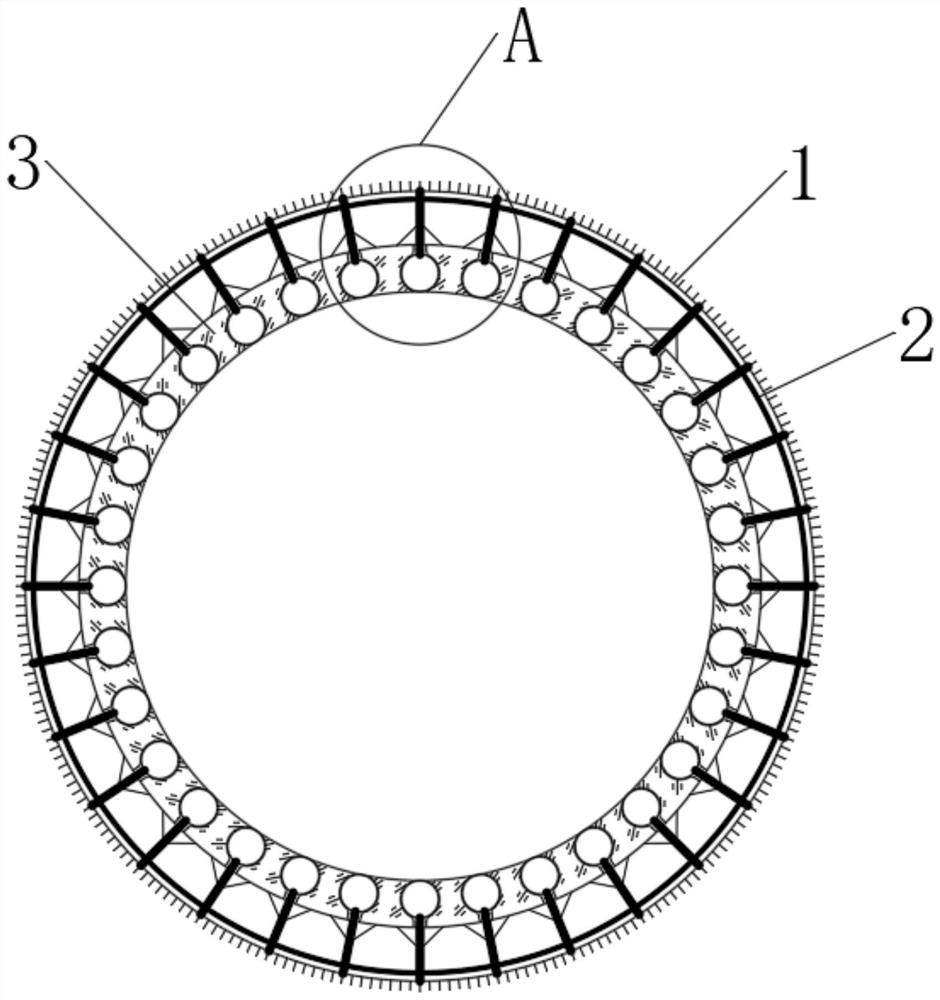

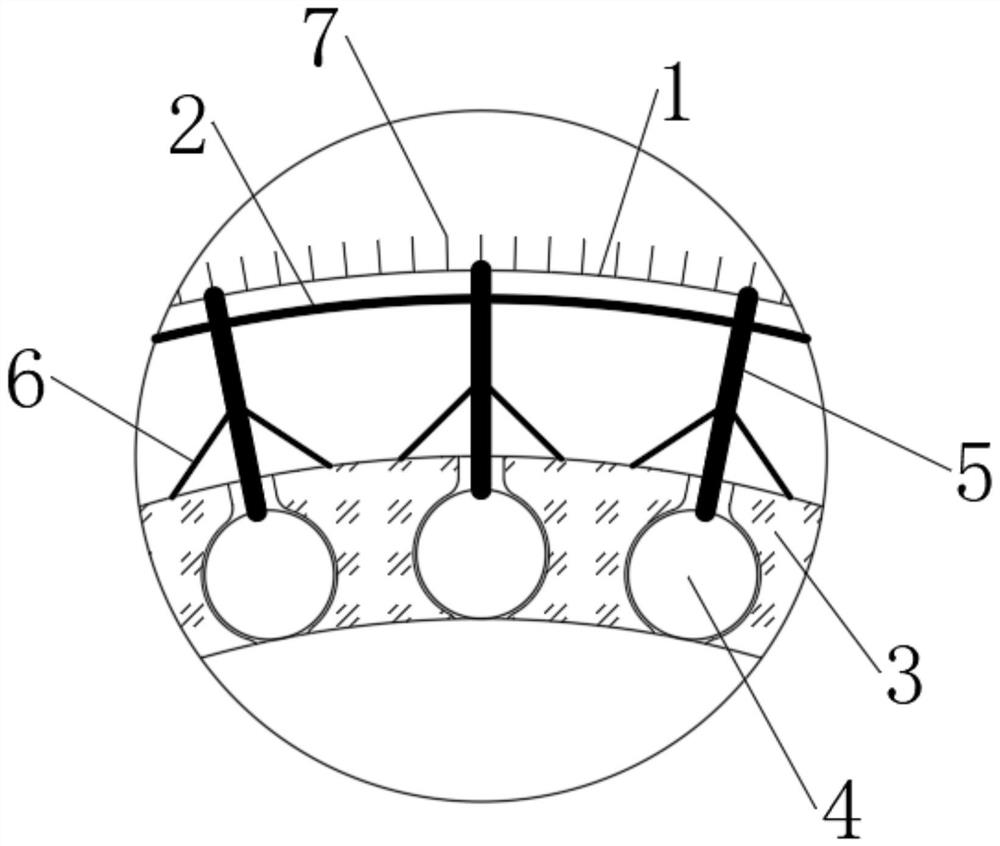

[0049] S2. After sieving, the oily sediment is evenly sprinkled onto the pre-oil-absorbing coating ball 1 from top to bottom, and the pre-oil-absorbing coating ball 1 coats the oily sediment and spits out the treated sediment;

[0050] S3. The sediment slides down on the pre-oil-absorbing coated ball 1 and enters the cleaning pool, and the oil is forced to concentrate on the water surface by means of ultrasonic cleaning and steam stripping;

[0051] S4, using an oil-water separator to extract crude oil, and then using a cyclone separator to separate the sediment;

[0052] S5. After the crude oil adsorbed on the pre-oil-absorbing coated ball 1 is desorbed, the pre-oil-coated ball 1 can be put into use repeatedly.

[0053] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com