Preparation method of rhamnose

A rhamnose and sugar solution technology, applied in the field of separation and purification of rhamnose, can solve the problems of low yield, large amount of organic solvent, and low purity of rhamnose finished products, achieve high separation and purification efficiency, and avoid production costs High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

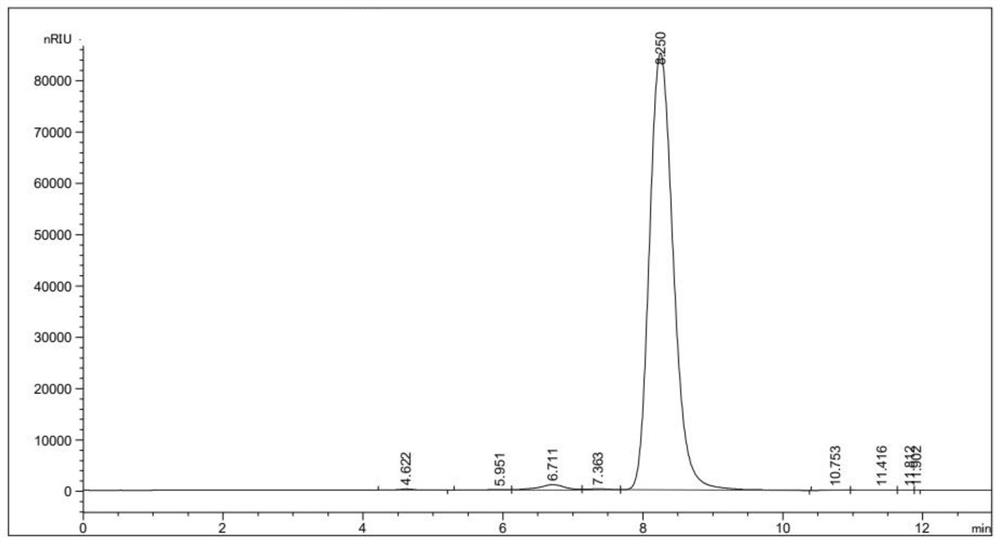

Embodiment 1

[0033] The present embodiment provides a kind of processing method of purifying rhamnose from glucose-containing sugar liquid, and specific processing method is as follows:

[0034] (1) Weigh 446g of pure water, heat it to 100°C and keep it warm for 30min. Weigh 358g of sugar solution, and when the pure water is naturally cooled to 52°C, dissolve the sugar solution in pure water and stir evenly to completely dissolve the sugar solution to form a reaction sugar solution. The mass percentage of glucose in the reaction sugar solution is 16 %, the sum of the mass percentages of glucose and rhamnose is 35%.

[0035] (2) Adjust the pH value of the reaction sugar solution to 5.5 with calcium hydroxide, then place the reaction sugar solution in a water bath at 52° C. and aerate the reaction sugar solution with oxygen at a rate of 1 L / min.

[0036] (3) Add 20mL of glucose oxidase (1.00g / mL, 20°C) and 20mL of catalase (1.06g / mL, 20°C) to the reaction sugar solution to obtain a reaction...

Embodiment 2

[0040] The present embodiment provides a kind of processing method of purifying rhamnose from glucose-containing sugar liquid, and specific processing method is as follows:

[0041] (1) Weigh 446g of pure water, heat it to 100°C and keep it warm for 30min. Weigh 206g of sugar solution, and when the pure water is naturally cooled to 52°C, dissolve the sugar solution in pure water and stir evenly to completely dissolve the sugar solution to form a reaction sugar solution. The mass percentage of glucose in the reaction sugar solution is 11.4 %, the sum of the mass percentages of glucose and rhamnose is 25%.

[0042] (2) Adjust the pH value of the reaction sugar solution to 5.5 with calcium hydroxide, then place the reaction sugar solution in a water bath at 52° C. and aerate the reaction sugar solution with oxygen at a rate of 1 L / min.

[0043](3) Add 16mL of glucose oxidase (1.00g / mL, 20°C) and 16mL of catalase (1.06g / mL, 20°C) to the reaction sugar solution to obtain a reactio...

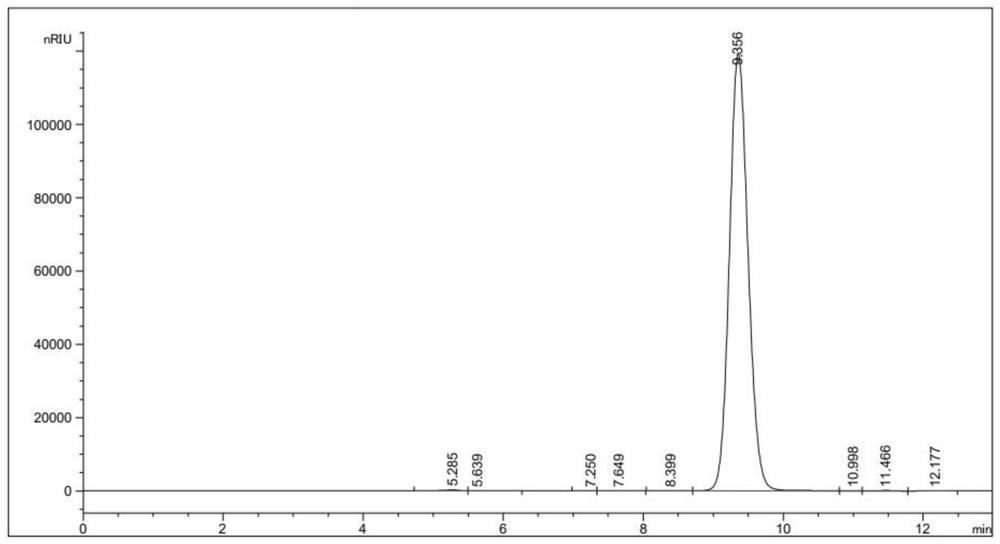

Embodiment 3

[0047] The present embodiment provides a kind of processing method of purifying rhamnose from glucose-containing sugar liquid, and specific processing method is as follows:

[0048] (1) Weigh 446g of pure water, heat it to 100°C and keep it warm for 30min. Weigh 304g of sugar solution, and when the pure water is naturally cooled to 52°C, dissolve the sugar solution in pure water and stir evenly to completely dissolve the sugar solution to form a reaction sugar solution. The mass percentage of glucose in the reaction sugar solution is 14.6 %, the sum of the mass percentages of glucose and rhamnose is 32%.

[0049] (2) Adjust the pH value of the reaction sugar solution to 5.5 with calcium hydroxide, then place the reaction sugar solution in a water bath at 52° C. and aerate the reaction sugar solution with oxygen at a rate of 1 L / min.

[0050] (3) Add 19mL of glucose oxidase (1.00g / mL, 20°C) and 19mL of catalase (1.06g / mL, 20°C) to the reaction sugar solution to obtain a reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com