Copper electroplating solution for heterojunction solar cell and preparation method of copper electroplating solution

A technology for solar cells and copper electroplating solution, which is applied in the field of metal surface treatment, can solve the problems of brittle coating, unsatisfactory coating quality, large coating stress, etc., and achieves the effects of small deposition stress, easy cracking, and improvement of cathode polarization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

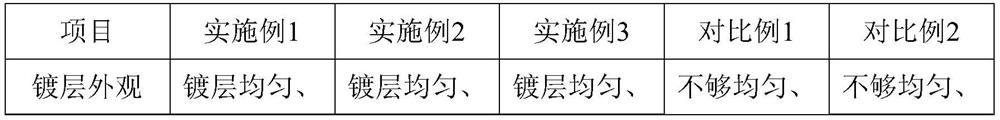

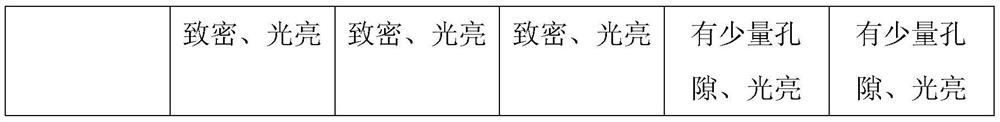

Embodiment 1

[0031] Embodiment 1. A copper electroplating solution for heterojunction solar cells

[0032] The copper electroplating solution for heterojunction solar cells includes copper salt, complexing agent, conductive salt, crystal refiner, stress reliever, brightener and pH stabilizer; the content of the copper salt is 28g / L, so The content of the complexing agent is 52g / L, the content of the conductive salt is 40g / L, the content of the crystal refiner is 2g / L, the content of the stress relief agent is 1g / L, the bright The content of the agent is 0.4g / L, and the content of the pH stabilizer is 35g / L; the copper salt is copper sulfate; the complexing agent is potassium citrate; the conductive salt is sodium chloride; The crystal refiner consists of saccharin, sodium propynyl sulfonate and polyvinyl alcohol in a mass ratio of 8:6:2; the stress reliever consists of 2-amino-6-mercaptopurine, 1,4-butynediol and The polyethyleneimine is composed of a mass ratio of 11:7:1; the brightener ...

Embodiment 2

[0039] Embodiment 2. A copper electroplating solution for heterojunction solar cells

[0040] The copper electroplating solution for heterojunction solar cells includes copper salt, complexing agent, conductive salt, crystal refiner, stress reliever, brightener and pH stabilizer; the content of the copper salt is 35g / L, so The content of the complexing agent is 60g / L, the content of the conductive salt is 46g / L, the content of the crystal refiner is 4g / L, the content of the stress relief agent is 3g / L, the bright The content of agent is 1g / L, and the content of described pH stabilizer is 45g / L; Described copper salt is cupric chloride; Described complexing agent is made up of citric acid and potassium tartrate by mass ratio 1:4; Described The conductive salt is sodium chloride; the crystal refiner is composed of saccharin, sodium propynyl sulfonate and polyvinyl alcohol in a mass ratio of 10:4:1; the stress relief agent is composed of 2-amino-6-mercaptopurine , 1,4-butynediol...

Embodiment 3

[0047] Embodiment 3. A copper electroplating solution for heterojunction solar cells

[0048] The copper electroplating solution for heterojunction solar cells includes copper salt, complexing agent, conductive salt, crystal refiner, stress reliever, brightener and pH stabilizer; the content of the copper salt is 33g / L, so The content of the complexing agent is 54g / L, the content of the conductive salt is 45g / L, the content of the crystal refiner is 3g / L, the content of the stress relief agent is 2g / L, the bright The content of agent is 0.7g / L, and the content of described pH stabilizer is 38g / L; Described copper salt is copper citrate; Described complexing agent is made up of citric acid and tartaric acid by mass ratio 2:7; Described The conductive salt is sodium chloride; the crystal refiner is composed of saccharin, sodium propynyl sulfonate and polyvinyl alcohol in a mass ratio of 10:5:1; the brightener is composed of nicotinic acid and phenyl dithiopropane sulfonate Sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com