Method for evaluating photoresist photoetching efficiency based on quartz crystal microbalance

A technology of quartz crystal and photoresist, applied in the direction of using optical devices, using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, instruments, etc., can solve problems such as expensive, time-consuming, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

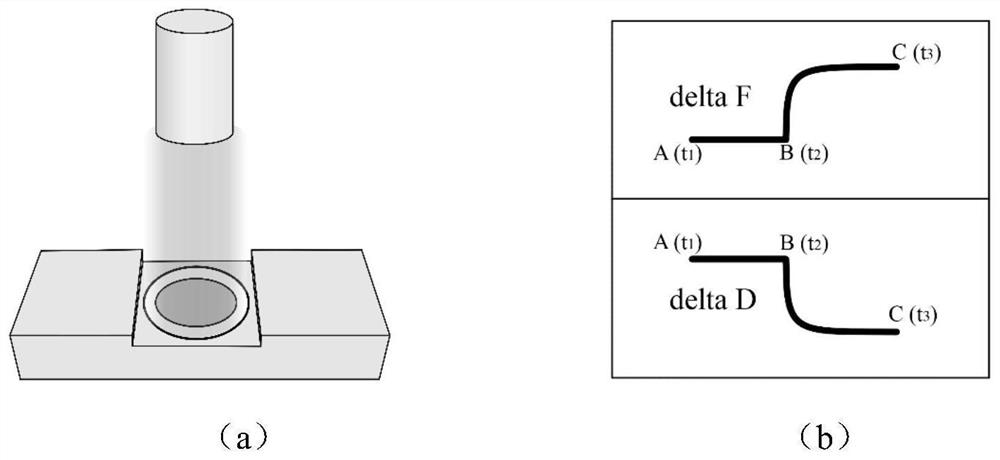

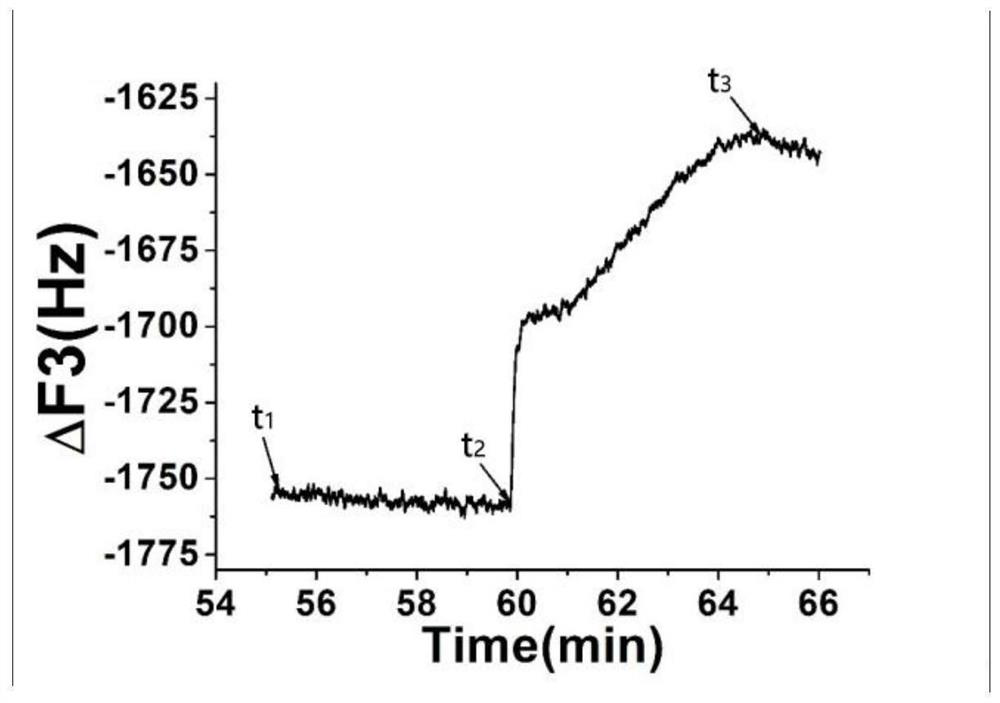

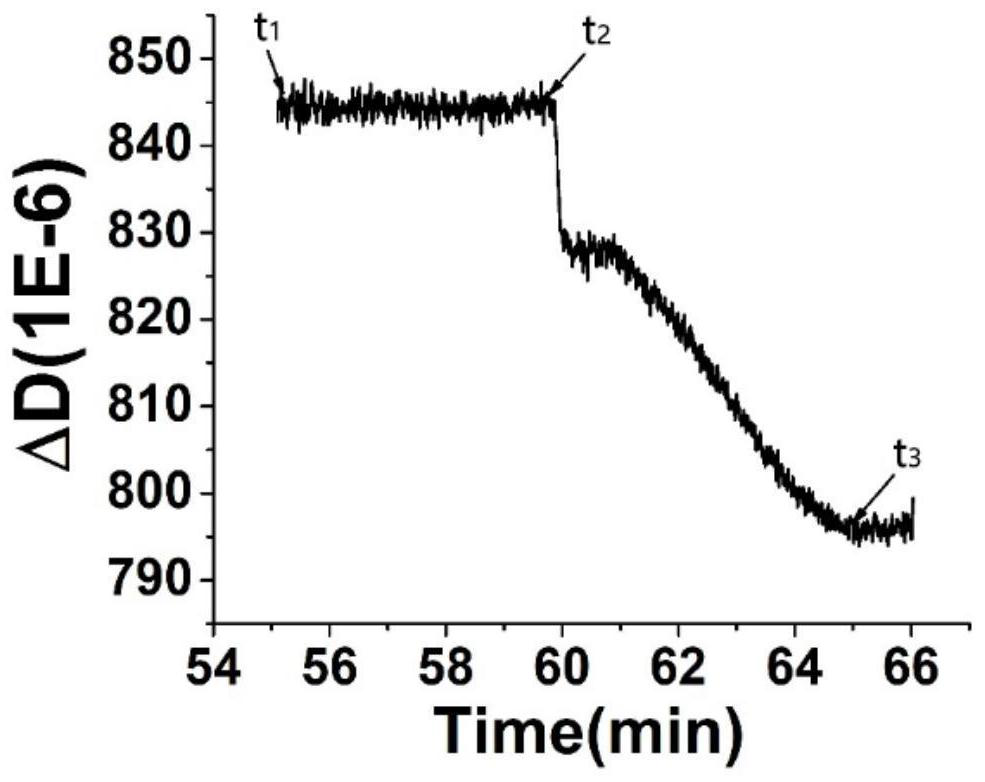

[0027]Fix the photoresist on the chip and use 365nm ultraviolet light for photodegradation treatment, so that the positive photoresist AZ1518 cured on the chip is dissolved and separated from the chip surface, such asfigure 1 Shown in (a). The changes of resonance frequency (△F) and energy dissipation (△D) in QCM are collected, and the degradation efficiency of photoresist by ultraviolet light is dynamically monitored in real time, so as to effectively evaluate the sensitivity and contrast of photoresist.

[0028]Specific steps are as follows:

[0029]Step 1: Put the QCM chip in a UV-ozone cleaner for 30 minutes, then clean it with deionized water and ethanol, and then dry it with nitrogen; the QCM with a sunroof is cleaned with deionized water and ethanol and then dry it with nitrogen.

[0030]Step 2: Fix the photoresist; pass the photoresist AZ1518 on the QCM chip under dark conditions, and the photoresist adheres to the surface of the chip to form a thin layer of colloid; then the fixed Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com