Low-chlorine chlorinated polypropylene with excellent solution stability at low temperature and preparation method oflow-chlorine chlorinated polypropylene

A technology of chlorinated polypropylene and solution stability, applied in the field of polypropylene resin, can solve problems such as increasing production cost, and achieve the effects of good fluidity and excellent low temperature dissolution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of maleic anhydride grafted polypropylene raw material:

[0055] (1) Equipment manufacturer: Coperion, model: CTE20 PLUS, nine-section barrel, screw diameter 20mm, aspect ratio 26.

[0056] (2) Operating parameters: 2000g polypropylene versify 4200, 60g maleic anhydride, 40g cumene hydroperoxide, 10g N,N-dimethylformamide (DMF) within the particle size range of 10-100 mesh Mix well and feed to CTE20 PLUS twin-screw extruder with a residence time of 10 minutes. The barrel temperature is set at 190°C (the first barrel - the eighth barrel) to react, and the eighth barrel is exhausted to remove unreacted maleic anhydride and DMF to obtain maleic anhydride modified propylene-based standard copolymer. The reaction material used in Example 5.

[0057] (3) The mensuration of maleic anhydride grafting ratio: get a certain amount of above-mentioned grafts and pelletize, in a certain amount of xylene, after heating to reflux and dissolving, precipitate wi...

Embodiment 1

[0067] The present embodiment synthesizes chlorinated polypropylene according to the following method:

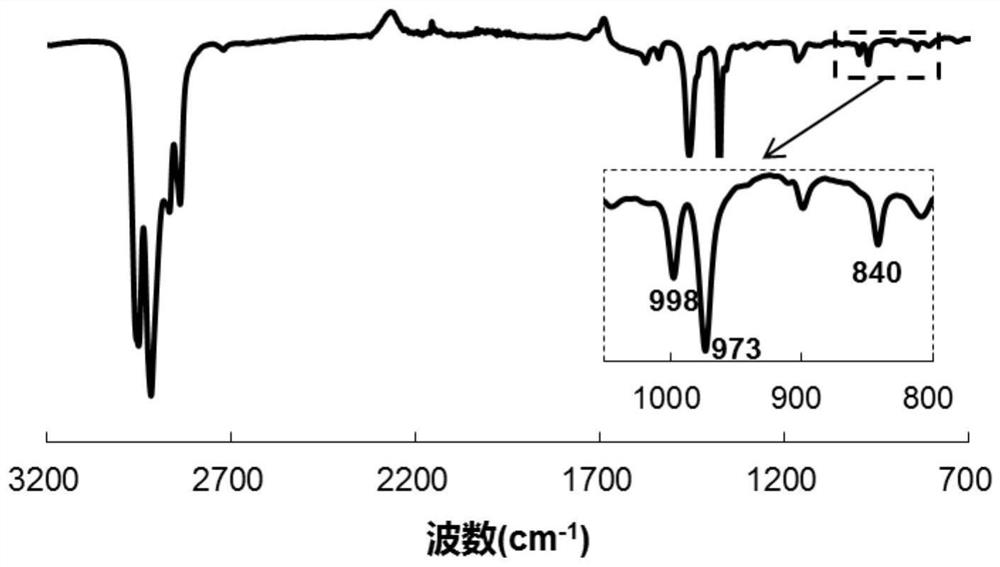

[0068] (1) Vistamaxx 6502, a commercially available grade of ExxonMobil grade random copolymerized polypropylene, is used. 6502 uses ethylene as a comonomer, and the propylene structure accounts for 87%. Characterized by infrared, the peak wave number is 998cm -1 / 973cm -1 The peak area ratio is 37%, and the peak wave number is 840cm -1 / 973cm -1 The peak area ratio was 26%. Its infrared spectrum is as figure 1 shown.

[0069] In a 20L enamel reaction kettle, add 10kg chlorobenzene and 1.5kg Vistamaxx 6502 (melt index 45g / 10min, weight average molecular weight 150,000, molecular weight distribution 2.2), heat up to 120°C, keep warm for 20min to completely dissolve the polypropylene, and then Cool down to 70°C and purge with nitrogen for 20 minutes;

[0070](2) Add 2.5g of azobisisobutyronitrile AIBN, continue purging with nitrogen for 10 minutes, turn off the nitroge...

Embodiment 2

[0079] The present embodiment synthesizes chlorinated polypropylene according to the following method:

[0080] (1) Use Japan's Idemitsu brand low-grade polypropylene, and the commercially available brand product L-MODU TM S600 is a homopolypropylene with an isotacticity of about 76%. Characterized by infrared, the peak wave number is 998cm -1 / 973cm -1 The peak area ratio is 55%, and the peak wave number is 840cm -1 / 973cm -1 The peak area ratio is 40%.

[0081] In a 20L enamel reaction kettle, add 10kg chlorobenzene and 1.5kg L-MODU TM S600 (melt index 350g / 10min, weight average molecular weight 75,000, molecular weight distribution 2.5), heat up to 120°C, keep warm for 20min to completely dissolve polypropylene, then cool down to 80°C, and purge with nitrogen for 20min;

[0082] (2) Add 2.5 dibenzoyl peroxide BPO, continue purging with nitrogen for 10 minutes, turn off the nitrogen, change to chlorine gas, the rate of chlorine gas introduction is 7.5g / min, the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com