Soft powder coating and preparation method thereof

A powder coating and soft-feeling technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of rising surface tension and the difficulty of applying soft-feel powder coatings to substrates, achieving low surface tension, strong resistance thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

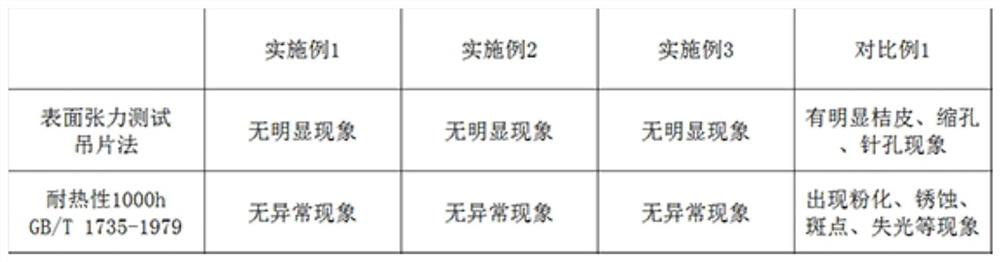

Examples

specific Embodiment approach

[0019] Specific implementation method: combined figure 1 Shown, a soft feeling powder coating and preparation method thereof, is characterized in that, epoxy resin 40-80 parts, saturated polyester resin 40-80 parts, pigment and filler 10-20 parts, curing agent 5-10 parts and modified 1-2 parts of property leveling agent; The modified leveling agent is the polydimethylsiloxane that adds the alkyl modifier, and the polydimethylsiloxane of the alkyl modifier and the polydimethylsiloxane The ratio of parts by weight is 2:1.

[0020] To further optimize this technical solution, the curing agent is a mixture of aromatic amines and aliphatic amines.

[0021] To further optimize this technical solution, the pigment and filler are a mixture of iron oxide red, carbon black and calcium carbonate.

[0022] A soft feeling powder coating and preparation method thereof, is characterized in that, comprises the following steps:

[0023] (1) Weigh 40-80 parts of epoxy resin, 40-80 parts of s...

Embodiment 1

[0033] A soft feeling powder coating, including 40 parts of epoxy resin, 40 parts of saturated polyester resin, 10 parts of pigment and filler, 5 parts of curing agent and 1 part of modified leveling agent; The polydimethylsiloxane of the neutralizing agent, the weight ratio of the alkyl modifier to the polydimethylsiloxane is 2:1. Wherein, the curing agent is a mixture of aromatic amines and aliphatic amines, and the pigment and filler is a mixture of iron oxide red, carbon black and calcium carbonate.

[0034] A kind of preparation method of soft feel powder coating, comprises the following steps:

[0035] (1) Weigh 40 parts of epoxy resin, 40 parts of saturated polyester resin, 10 parts of pigment and filler, 5 parts of curing agent and 1 part of modified leveling agent and place them in a mixing tank, stir and mix at high speed for 5 minutes to obtain premixed materials;

[0036] (2) Extruding the premixed material through a twin-screw extruder, pressing into tablets, co...

Embodiment 2

[0043] A kind of soft powder coating, including 80 parts of epoxy resin, 80 parts of saturated polyester resin, 20 parts of pigment and filler, 10 parts of curing agent and 2 parts of modified leveling agent; The polydimethylsiloxane of the neutralizing agent, the weight ratio of the alkyl modifier to the polydimethylsiloxane is 2:1. Wherein, the curing agent is a mixture of aromatic amines and aliphatic amines, and the pigment and filler is a mixture of iron oxide red, carbon black and calcium carbonate.

[0044] A kind of preparation method of soft feel powder coating, comprises the following steps:

[0045] (1) Weigh 80 parts of epoxy resin, 80 parts of saturated polyester resin, 20 parts of pigments and fillers, 10 parts of curing agent and 2 parts of modified leveling agent and place them in a mixing tank, stir and mix at high speed for 5 minutes to obtain premixed materials;

[0046] (2) Extruding the premixed material through a twin-screw extruder, pressing into table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com