Photographic fixing system cleaning agent and preparation method thereof

A cleaning agent, a technology of sodium sesquicarbonate, applied in the field of cleaning, can solve the problem of unclean cleaning of the fixing cylinder, and achieve the effects of saving cleaning time, convenient use and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

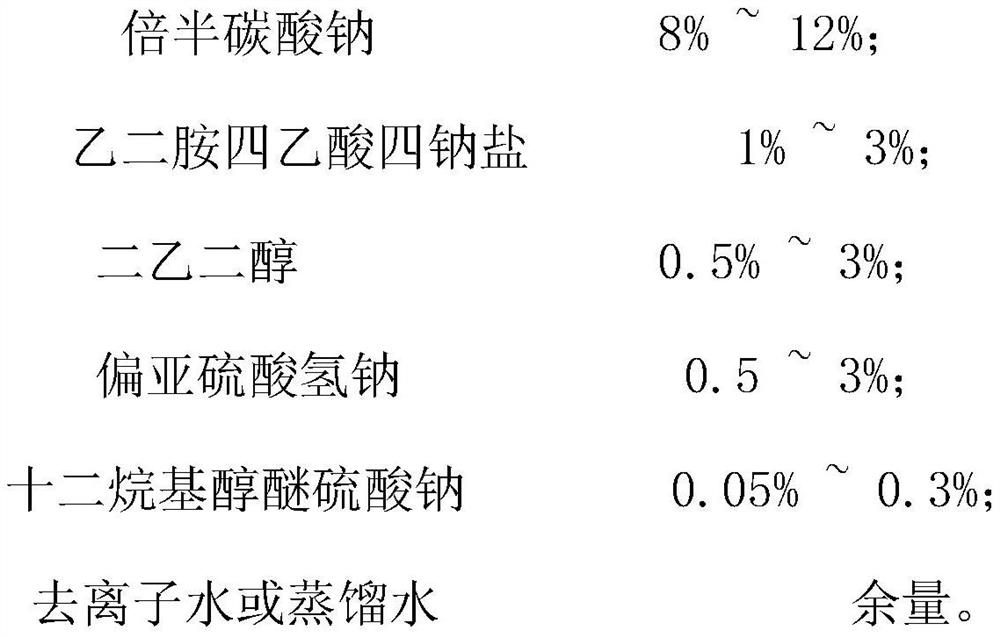

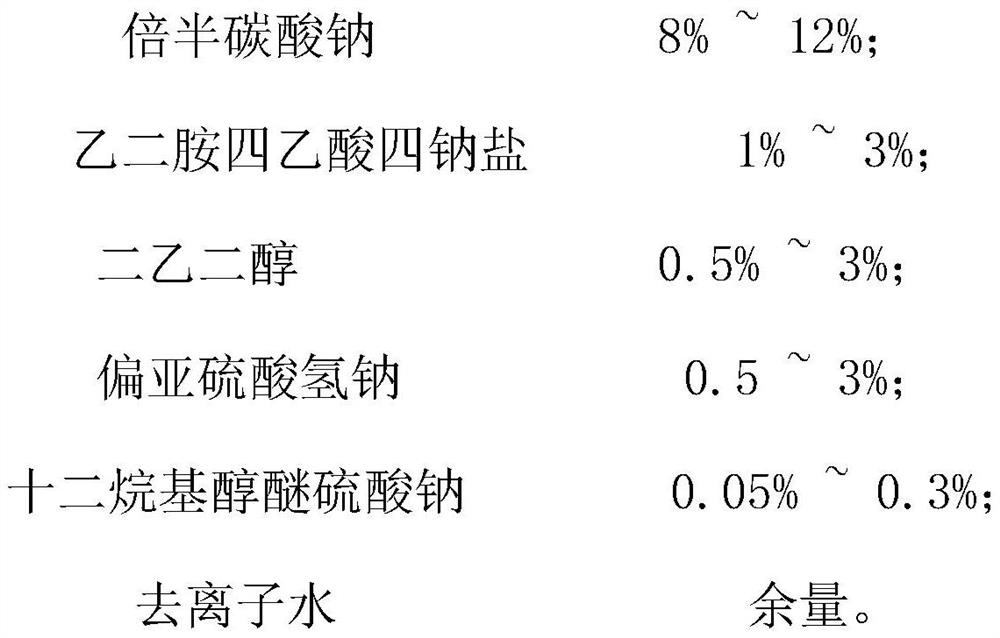

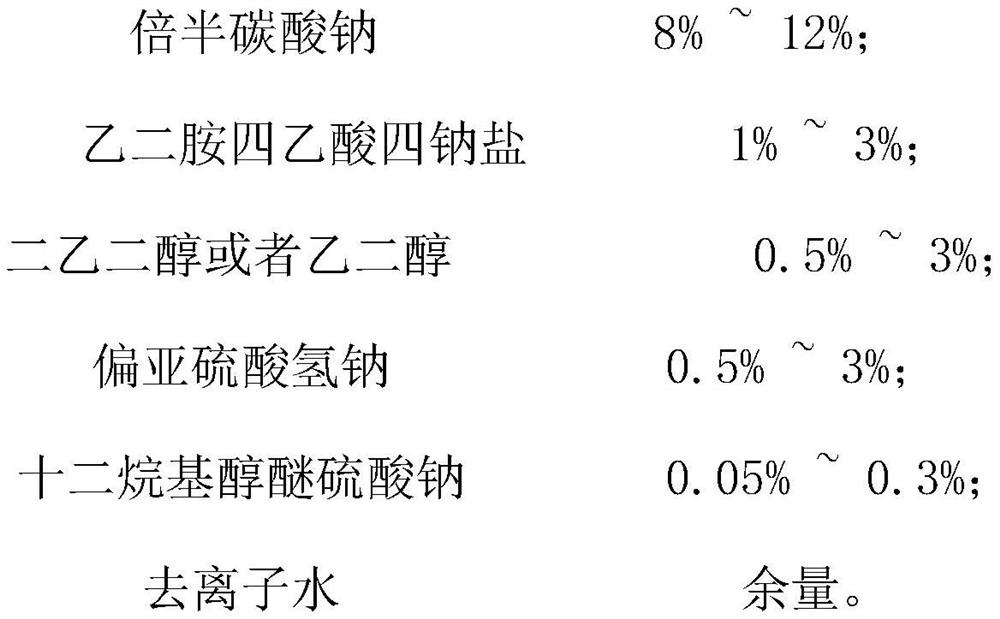

[0034] A preparation method of a fixing system cleaner, the steps are as follows:

[0035] Add deionized water or distilled water into the stainless steel container, stir, add sodium sesquicarbonate, ethylenediaminetetraacetic acid tetrasodium salt, diethylene glycol or ethylene glycol, sodium metabisulfite, continue stirring for a period of time, the Stirring speed, add surfactant sodium lauryl alcohol ether sulfate, make up the remaining water and continue stirring to obtain a transparent colorless liquid.

[0036] Further, its preparation method, the steps are as follows:

[0037] The following are based on a weight ratio of 1:

[0038] S1: Add 700 parts of deionized water or distilled water to a 1000-liter clean stainless steel container, and control the water temperature at 30°C-50°C;

[0039] S2: the solution in S1 is stirred, and the rotating speed is at 100 rpm-150 rpm;

[0040] S3: Under stirring, gradually add 80 parts-120 parts of sodium sesquicarbonate; 10 parts...

Embodiment 1

[0051] S1: Add 700 kg of deionized water or distilled water to a 1000 liter cleaned stainless steel container, and control the water temperature at 30°C-50°C;

[0052] S2: the solution in S1 is stirred, and the rotating speed is at 100 rpm-150 rpm;

[0053] S3: under stirring, gradually add 115 kilograms of sodium sesquicarbonate; 23 kilograms of tetrasodium edetate; 20 kilograms of diethylene glycol or ethylene glycol; 10 kilograms of sodium metabisulfite;

[0054] S4: continue stirring for 20 minutes-30 minutes;

[0055] S5: reduce stirring speed and be 30 revs / min-50 revs / min, slowly add 2 kilograms of surfactant sodium lauryl alcohol ether sulfates;

[0056] S6: Supplement the remaining amount of water so that the total amount of the solution is 1000 liters, continue to stir for 30 minutes, and cool down to 20°C-30°C to obtain a transparent colorless liquid.

[0057] Get 500 milliliters of solution and send it to the laboratory for inspection; the physical properties of ...

Embodiment 2

[0060] S1: Add 700 kg of deionized water or distilled water to a 1000 liter cleaned stainless steel container, and control the water temperature at 30°C-50°C;

[0061] S2: the solution in S1 is stirred, and the rotating speed is at 100 rpm-150 rpm;

[0062] S3: under stirring, gradually add 84 kilograms of sodium sesquicarbonate; 10.5 kilograms of ethylenediaminetetraacetic acid tetrasodium salt; 5.25 kilograms of diethylene glycol or ethylene glycol; 5.25 kilograms of sodium metabisulfite;

[0063] S4: continue stirring for 20 minutes-30 minutes;

[0064]S5: reduce stirring speed and be 30 revs / min-50 revs / min, slowly add surfactant sodium lauryl ether sulfate 0.525 kilograms;

[0065] S6: Supplement the remaining amount of water so that the total amount of the solution is 1000 liters, continue to stir for 30 minutes, and cool down to 20°C-30°C to obtain a transparent colorless liquid.

[0066] Get 500 milliliters of solution and send it to the laboratory for inspection; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com