Silicon carbide plate heat exchanger

A technology of silicon carbide plates and silicon carbide plates, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger sealing devices, etc., can solve the problems of heat exchange equipment corrosion and scrapping, achieve simple structure, and solve low temperature dew point The effect of corrosion and large heat exchange space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

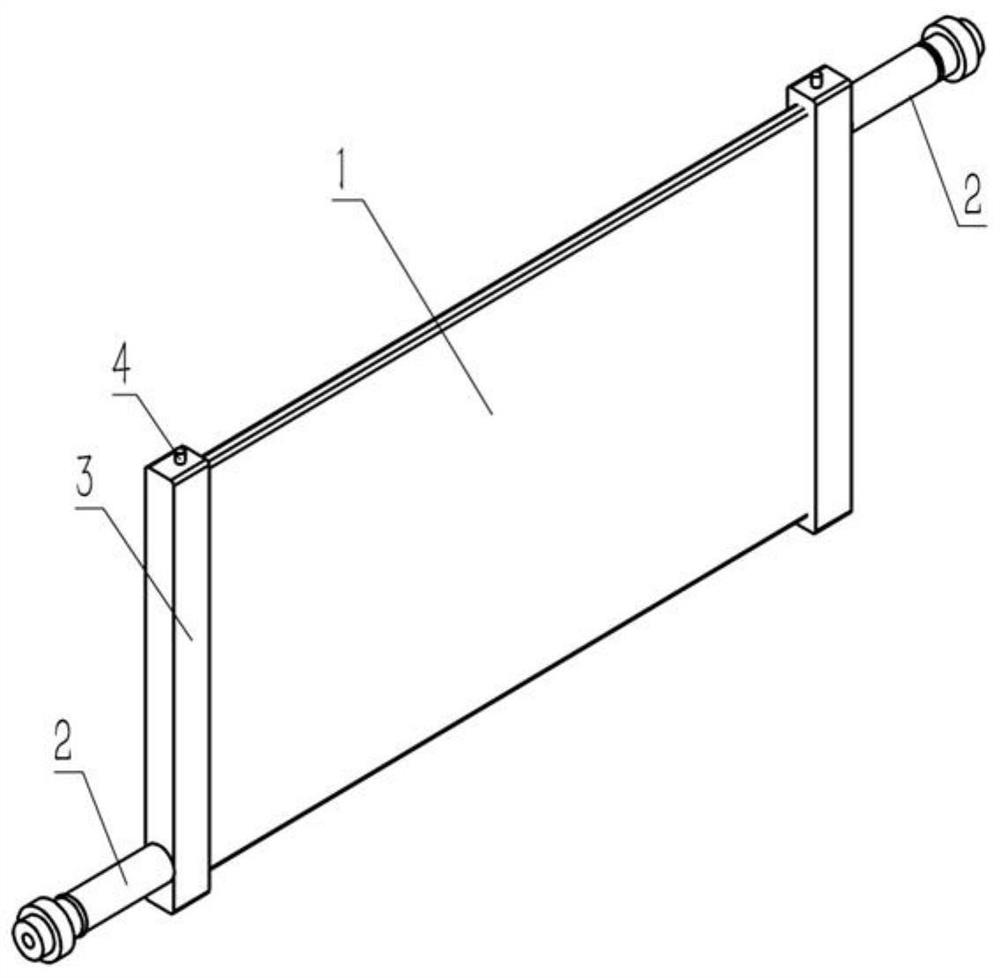

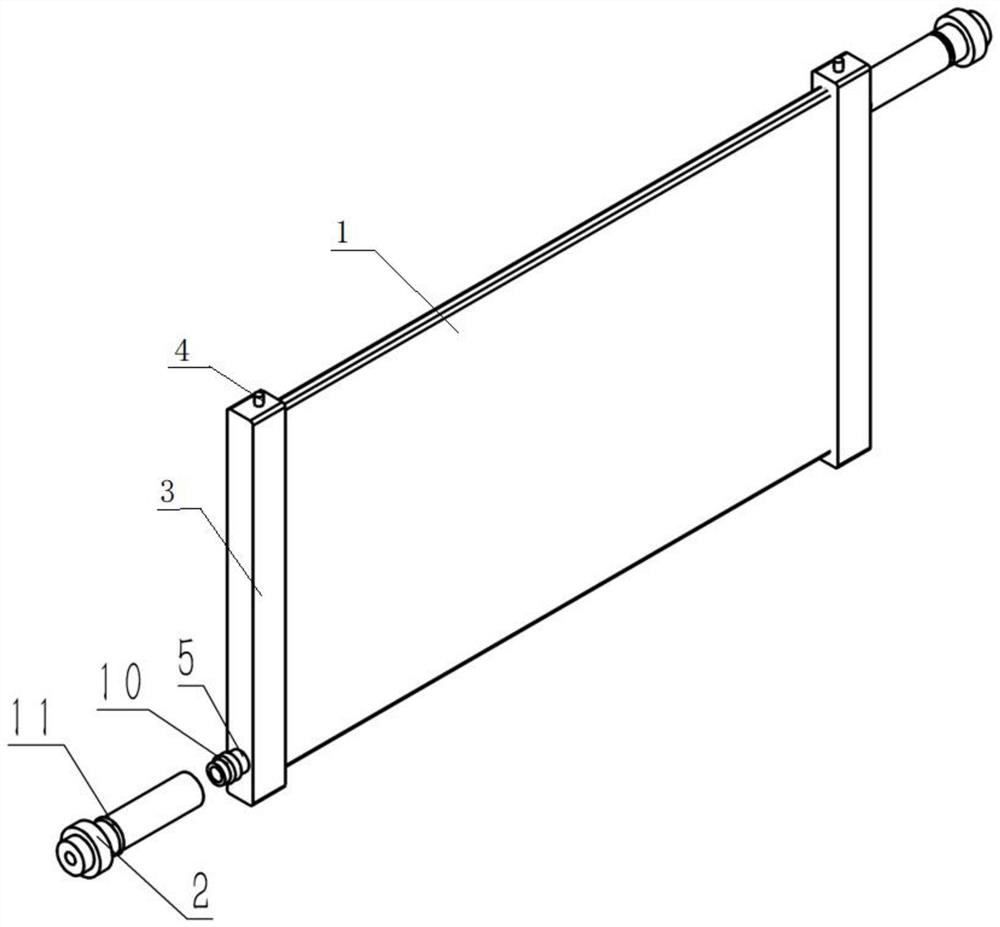

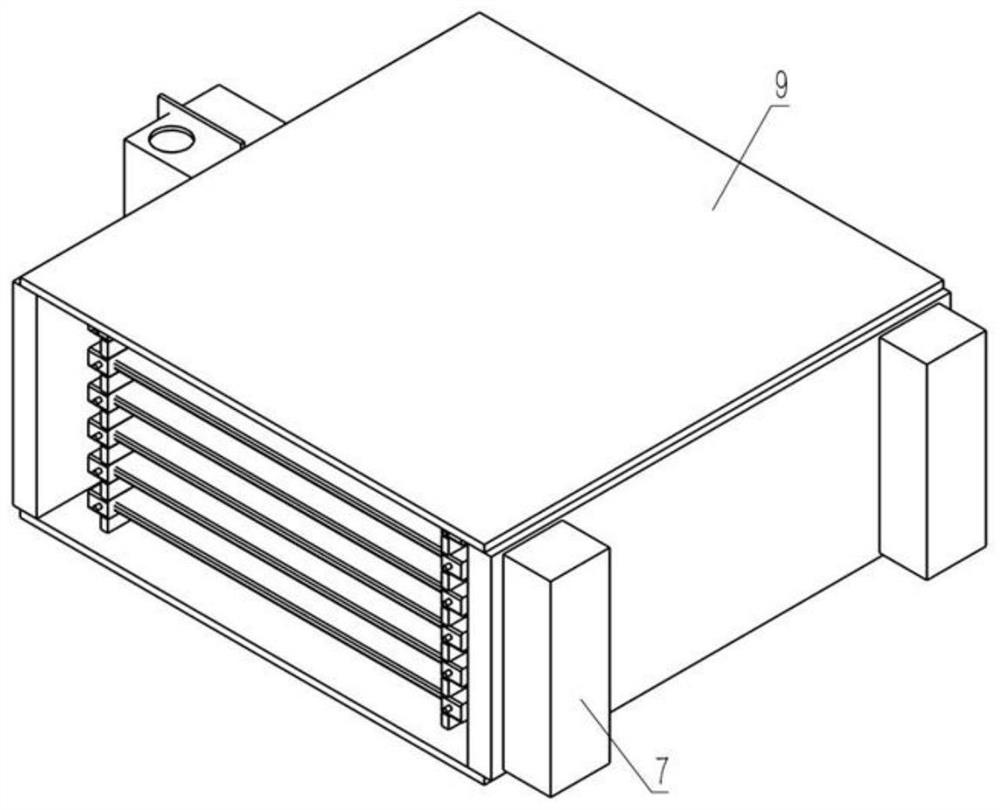

[0027] Example 1, such as Figure 1 to Figure 6 As shown, the present invention is a silicon carbide plate heat exchanger, which includes a heat exchange box, a heat exchange assembly is arranged in the heat exchange box, and a flue gas inlet pipe 12 and a flue gas outlet are arranged at the front and rear ends of the heat exchange box The pipeline 13 is characterized in that: the heat exchange assembly includes a plurality of silicon carbide heat exchange plates stacked in the heat exchange box, and there is a gap between adjacent silicon carbide heat exchange plates, and each silicon carbide heat exchange plate includes a silicon carbide heat exchange plate Plate 1, the silicon carbide plate 1 is provided with a plurality of water delivery holes 15 along the width direction, the two ends of the water delivery holes 15 extend to the two ends of the silicon carbide plate 1, and the two ends of the silicon carbide The liquid shell 3 is connected with connecting pipes 2 on the o...

Embodiment 2

[0039] Embodiment 2 is different from Embodiment 1 in that the connecting pipes 12 on both sides can be changed into long plastic hoses made of PTFE or PA, and the tube plates 6 and pipe boxes 7 on both sides can be changed into water inlet and outlet collectors on both sides. There is a row of water inlet or outlet ports on the liquid collection pipe. One end of the long plastic hose is connected to the short joint 5 on the silicon carbide plate 1, and the other end is connected to the liquid collection pipe. In this way, the water flows from the liquid collection pipe. One end enters, enters the silicon carbide plate 1 through a long plastic hose, and after exchanging heat with the flue gas, flows out through the other end of the long plastic hose to the liquid collector on the other side to complete the heat exchange.

Embodiment 3

[0040] Example 3, such as Figure 7 to Figure 9 As shown, on the basis of Embodiment 1, a support platform is provided at the outer end of the inner hole of the connection flange pipe 14 at one end of the flue gas inlet pipe 12, and a support sleeve 17 is provided inside the connection flange pipe 14, and the outer end of the support sleeve 17 is outside Be fixed with the supporting edge that cooperates with supporting table, be provided with positioning post 26 on supporting table, be provided with positioning jack on supporting edge, be fixed with supporting ring 20 on the inner hole wall of supporting sleeve 17 left ends, the left side of supporting ring 20 is provided with Screen mesh ring one 25, in the endoporus of screen mesh ring one 25, be fixed with the center to the spherical screen mesh one 23 of sunken right side, the left side of screen mesh ring one 25 is provided with spacer 21, the left side of spacer 21 The side is provided with screen mesh ring two 22, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com