Conveyor belt achieving waste sorting

A conveyor belt and waste technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of manual operation, safety, hidden dangers, and the inability of robots to fully identify and grasp, so as to achieve simple device design and improve The effect of high efficiency and operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

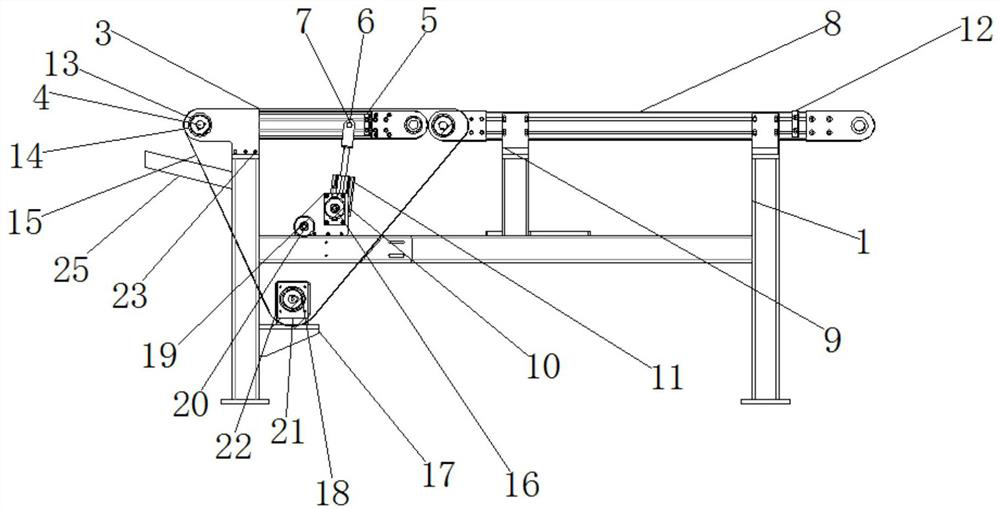

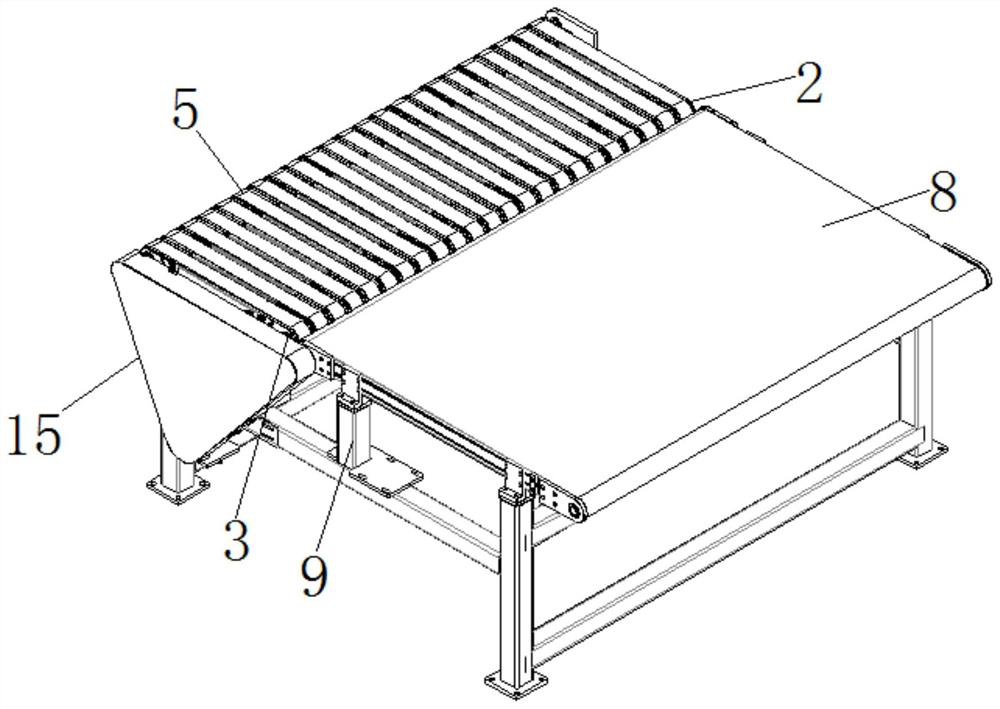

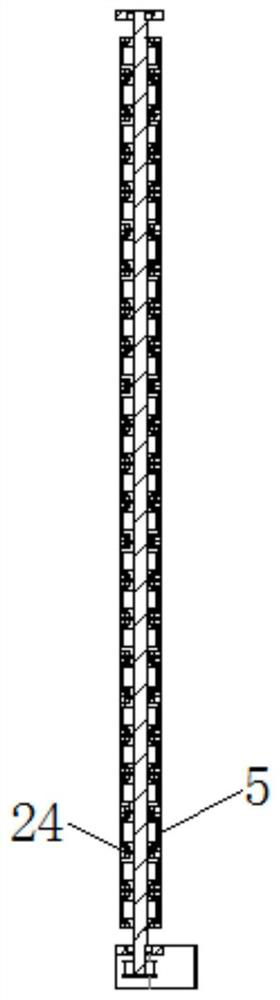

[0021] like Figure 1-3 As shown, the present invention provides a technical solution: the conveyor belt realizes waste sorting, including a frame 1, the top end of the frame 1 is rotatably connected with a belt drive shaft 4, and the outer wall of the belt drive shaft 4 is connected with a first Belt set 5, a U-shaped plate 6 is installed below the first belt set 5, a second belt set 8 is installed on one side of the first belt set 5, and a fixed block 10 is installed below the U-shaped plate 6, so A cylinder 11 is installed on the inner wall of the fixed block 10, an adjustment block 12 is installed on the outer end of the second belt set 8, and a first synchronous pulley 14 is arranged on the outer side of the frame 1, and the first synchronous pulley 14 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com