Method and system for preparing sodium hypochlorite from fly ash

A technology of sodium hypochlorite and fly ash, which is applied in the field of fly ash treatment, can solve the problems of rising economic costs, large chemical raw materials, energy consumption, and consumption, and achieve the effects of water saving, environmental friendliness, and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

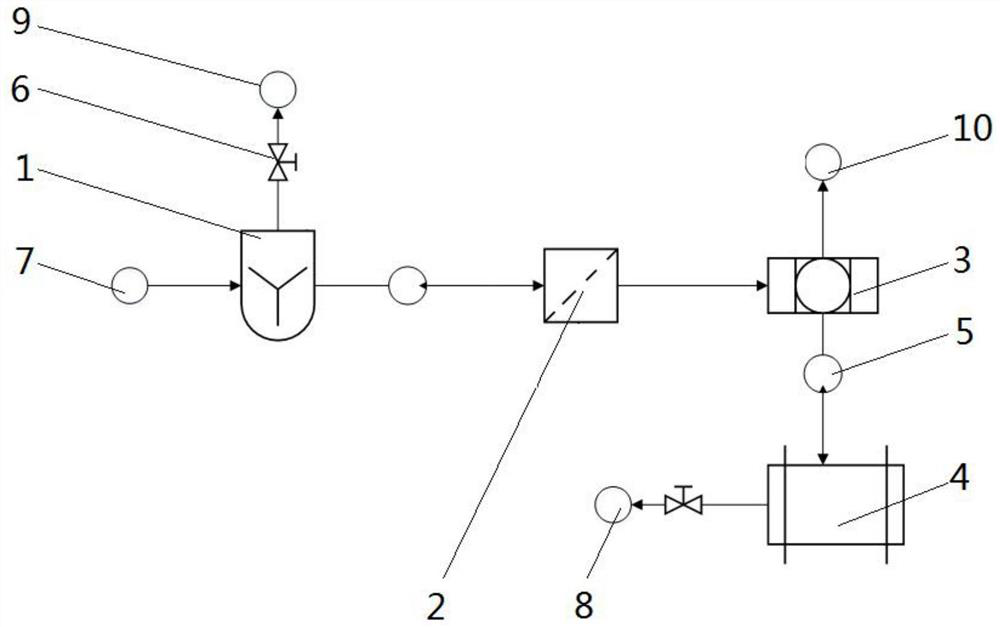

[0031] Such as figure 1 Shown, a kind of system that prepares sodium hypochlorite with fly ash, comprises washing tank 1, nanofiltration equipment 2, reverse osmosis device 3, electrolysis reactor 4, the first outlet of described washing tank 1 is connected with the inlet of nanofiltration equipment 2 Pass, the first outlet of described nanofiltration equipment 2 is communicated with the inlet of reverse osmosis device 3, and the first outlet of described reverse osmosis device 3 is communicated with the inlet of electrolytic reactor 4, and the first outlet of described washing pool 1 A high-pressure pump 5 is provided, and a stop valve 6 is provided at the second outlet of the water washing tank 1 and the second outlet of the electrolytic reactor 4 .

[0032] Among them, the washing tank 1 is used for washing fly ash, and the fly ash 7 enters the washing tank 1 and an appropriate amount of water is added to adjust the ratio of water: fly ash = 4:1. The stirring rate is 200-2...

Embodiment 2

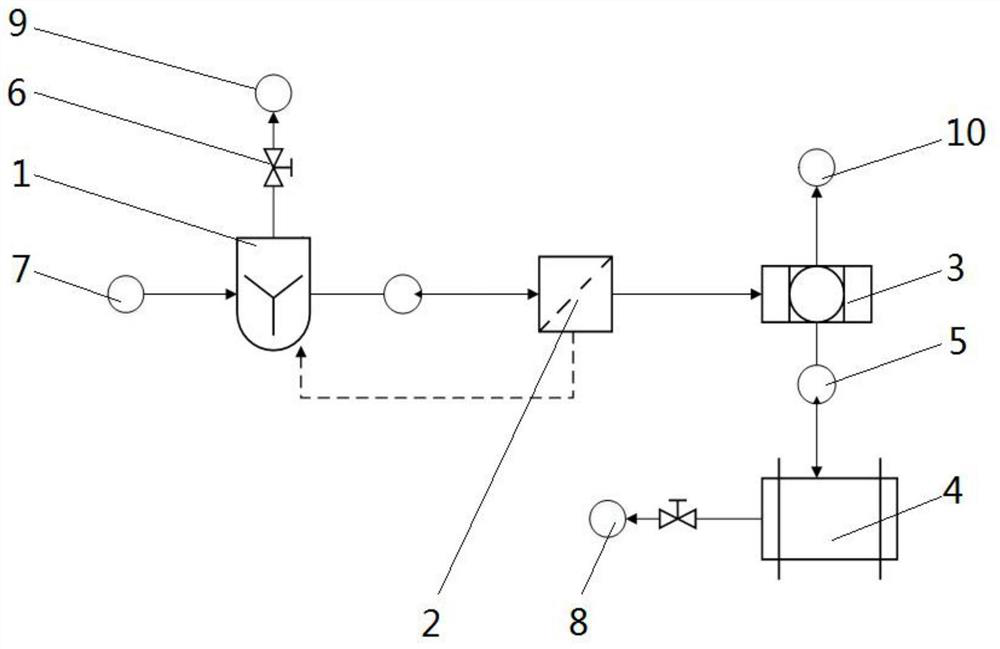

[0046] Such as figure 2 As shown, as an improvement of the present invention, the nanofiltration device 2 is used to perform nanofiltration treatment on the washing liquid, and the retained liquid after the nanofiltration contains a large amount of divalent ions such as calcium and magnesium ions and sulfate radicals, and can be used as a high salt water Washing the fly ash separately saves the overall water consumption in the washing process. All the other structures and advantages are identical to Embodiment 1.

Embodiment 3

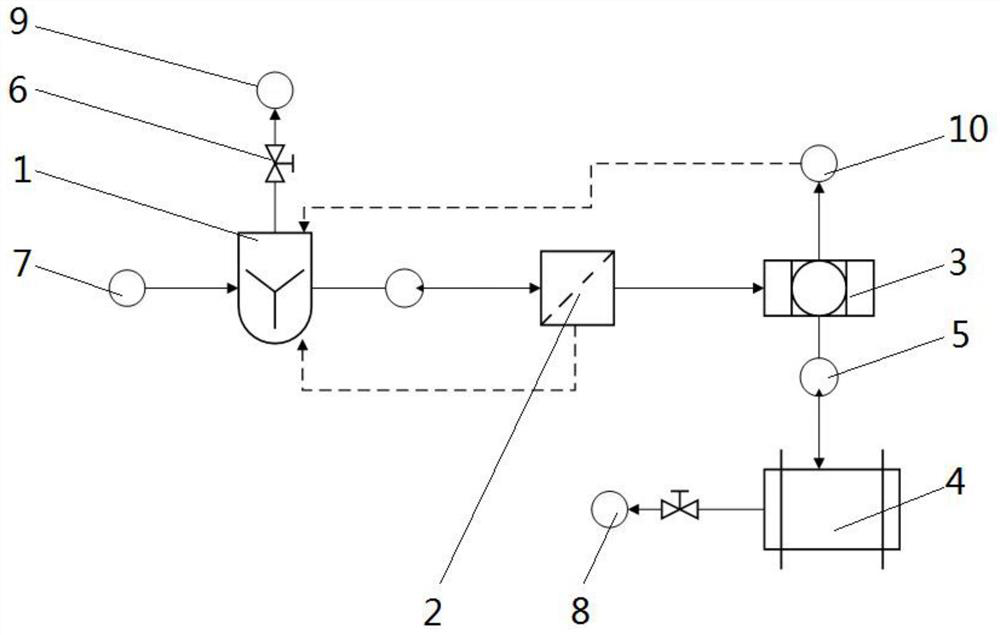

[0048] Such as image 3 As shown, as an improvement of the present invention, the reverse osmosis device 3 is used to perform reverse osmosis treatment on the solution after nanofiltration again, and the permeate and retentate permeate can be obtained through reverse osmosis treatment, and the retentate is mainly concentrated NaCl and KCl solution, the permeate composition is desalted water 10 that removes soluble salts, and the permeate can be used as desalinated water 10 to wash the fly ash separately, saving water consumption in the washing process. All the other structures and advantages are exactly the same as in Embodiment 2.

[0049] Such as Figure 5 Shown, a kind of method for preparing sodium hypochlorite with fly ash may further comprise the steps:

[0050] Step 1: The content of NaCl in the fly ash is 3%-9.5%. Pour the fly ash into the washing pool 1 and add an appropriate amount of water. The ratio of water and fly ash 7 is 4:1, and the stirring rate of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com