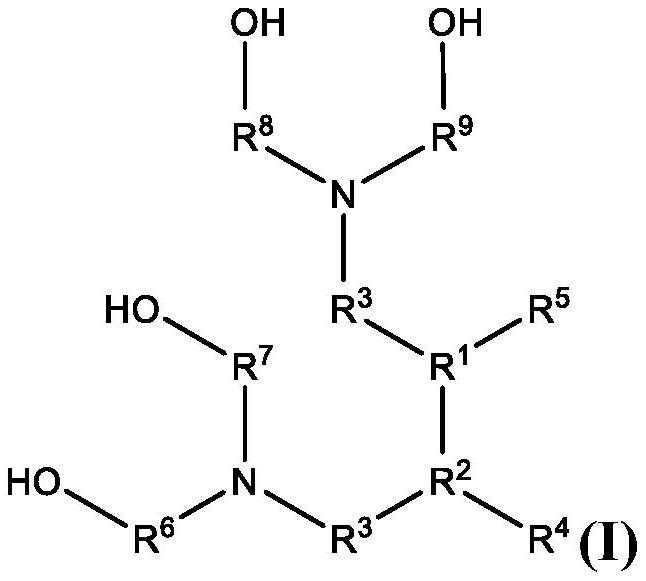

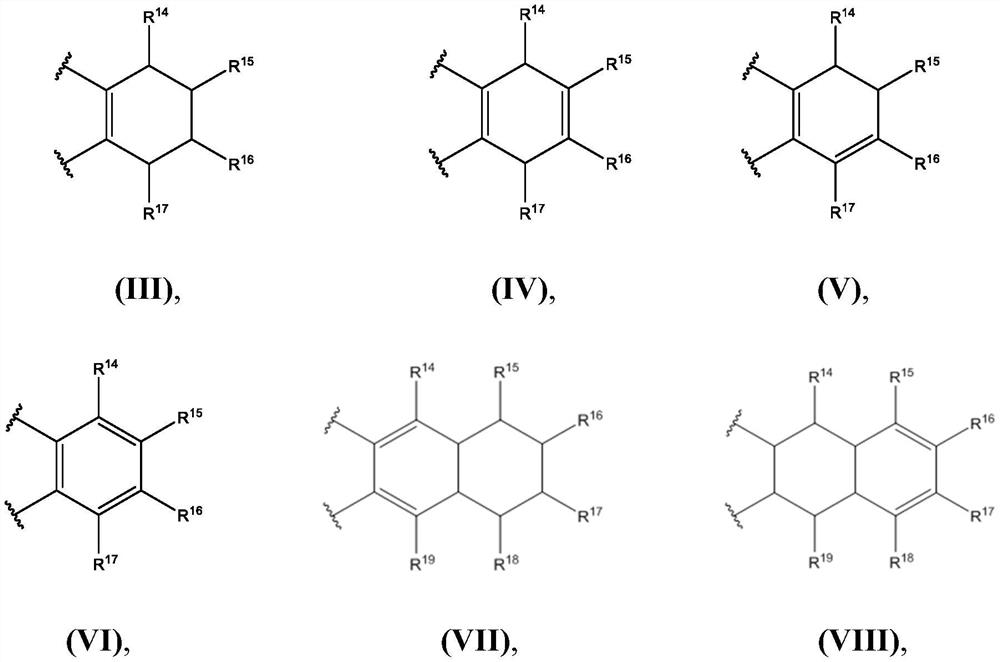

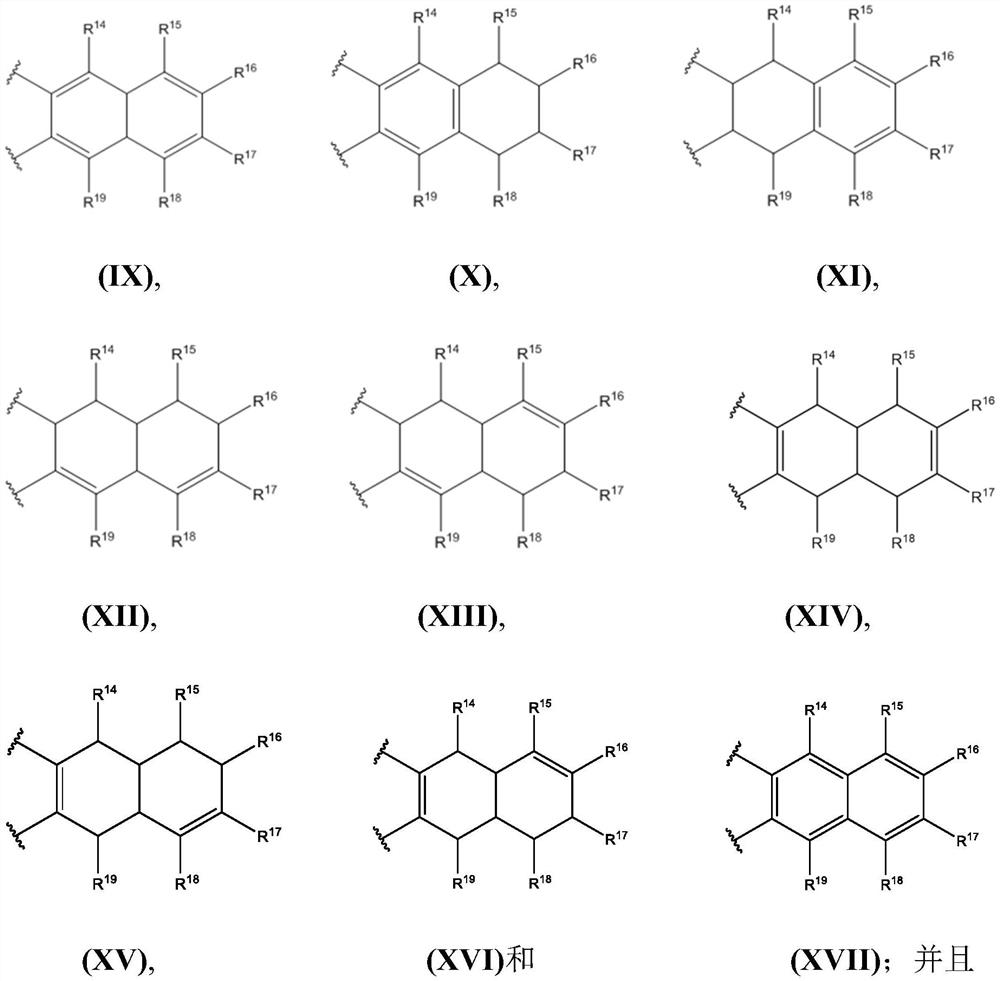

N-hydroxyalkylated polyamines, methods of making n-hydroxyalkylated polyamines, and fluids containing an n-hydroxyalkylated polyamine

A technology of hydroxyalkylation and polyamines, applied in the field of N-hydroxyalkylation polyamines, preparation of N-hydroxyalkylation polyamines and fluids containing N-hydroxyalkylation polyamines, which can solve difficult synthesis , poor compound performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080]In order to prove that the rheological properties of drilling fluids containing N-hydroxyalkylated polyamines have been improved, some tests were carried out, and drilling fluids containing N-hydroxyalkylated polyamines rheology modifiers (Example 1) It was compared with a drilling fluid containing a commercially available dimer diamine rheology modifier (Comparative Example 1) and a drilling fluid containing a commercially available dimer acid rheology modifier (Comparative Example 2). The formulations of these drilling fluid examples are shown in Table 1. Except for the rheology modifier composition, each drilling fluid example is the same.

[0081]Table 1: Composition of Comparative Examples 1 and 2 and Example 1

[0082]

[0083]In Table 1, "bbl" stands for barrel, which equals approximately 42 US gallons or 159 liters. Similarly, "lb / bbl" stands for pounds per barrel.V refers to an organophilic clay tackifier, commercially available from Halliburton (Ontario, CA). Lime refers to c...

Embodiment 1

[0086]The N-hydroxyalkylated polyamine of Example 1 was obtained by making PriamineTM1074 is produced by reacting with ethylene oxide. Commercial dimer diamine (Priamine 1074) was added to a 500 milliliter (mL) Parr reactor, sealed, and then bubbled with nitrogen at 120°C for one hour to drive out any oxygen and water from the solution. The system was then sealed and vented to atmospheric pressure. Add ethylene oxide from a gas cylinder containing 99.9% ethylene oxide via a swagelock quick connection. Determine the quality of the oxide by subtracting the tare valve cylinder. As ethylene oxide is added, the pressure in the vessel increases, and then the ethylene oxide reacts and transforms from the gas phase to the liquid phase, causing the pressure to drop. Add ethylene oxide until the theoretical maximum of 4 moles of ethylene oxide to 1 mole of priamine is reached, or the weight ratio of priamine to ethylene oxide is 1:0.36. When other amine-amines are used as reactants, the theor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com