Formula of cannabidiol soft-jelly candy and preparation process

A cannabidiol and preparation technology, which is applied in the field of cannabidiol soft gum candy formula and preparation technology, can solve the problems of no curative effect and limited number of recipients, and achieve the effects of reducing damage, increasing cell density, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

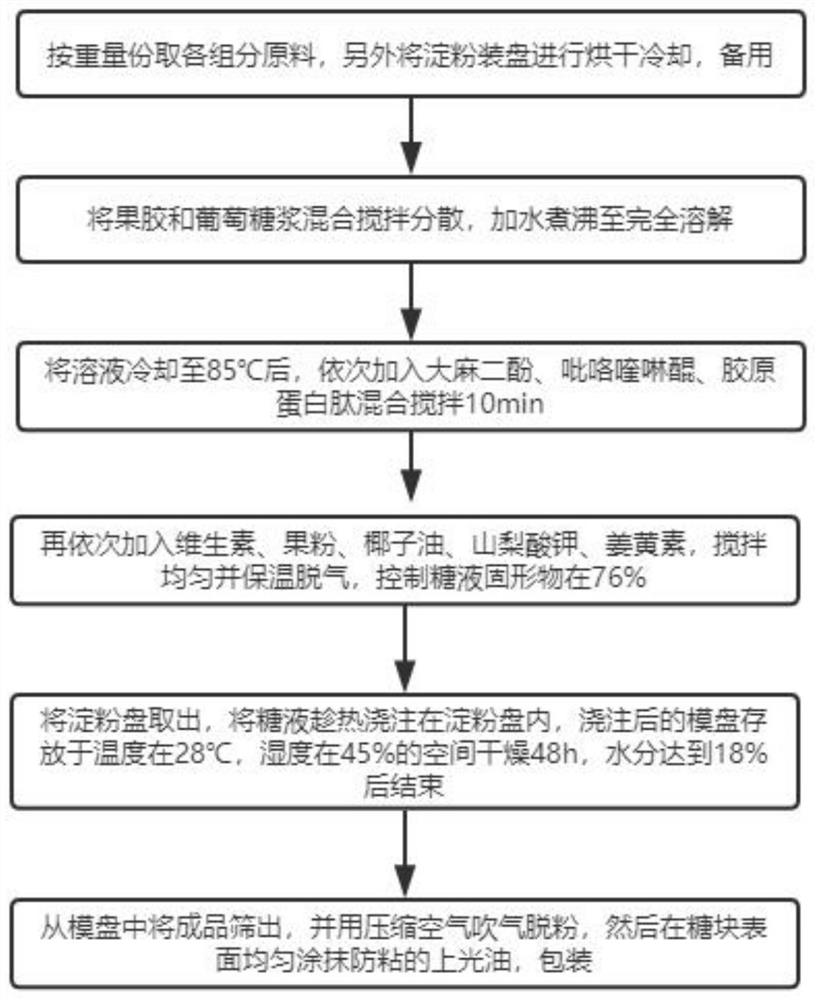

[0054] A cannabidiol soft gum candy formula, such as figure 1 As shown, it includes the following components by weight: 15 parts of cannabidiol, 15 parts of pyrroloquinoline quinone, 18 parts of collagen peptide, 30 parts of glucose syrup, 10 parts of pectin, 2.5 parts of vitamins, 3 parts of fruit powder, and 4 parts of coconut oil , 1 part of potassium sorbate, 0.5 part of curcumin, and the balance is water.

[0055] The preparation technology of described cannabidiol comprises the steps:

[0056] S1: drying hemp leaves and hemp flowers at 110 degrees Celsius for 1 hour to obtain raw materials with a moisture content of less than 5%, crushing the raw materials, and passing through a 60-mesh sieve to obtain powder;

[0057] S2: The obtained powder is subjected to supercritical carbon dioxide extraction, and an entrainer is added during the extraction. The weight ratio of the entrainer to the powder is 0.3:100 to obtain a solution and a residue;

[0058] S3: The residue is s...

Embodiment 2

[0094] A cannabidiol soft gum candy formula, such as figure 1 As shown, it includes the following components by weight: 16 parts of cannabidiol, 17 parts of pyrroloquinoline quinone, 15 parts of collagen peptide, 28 parts of glucose syrup, 12 parts of pectin, 2 parts of vitamins, 4 parts of fruit powder, and 3 parts of coconut oil , 1.5 parts of potassium sorbate, 0.5 part of curcumin, and the balance is water.

[0095] The preparation technology of described cannabidiol comprises the steps:

[0096] S1: drying hemp leaves and hemp flowers at 110 degrees Celsius for 1 hour to obtain raw materials with a moisture content of less than 5%, crushing the raw materials, and passing through a 60-mesh sieve to obtain powder;

[0097] S2: The obtained powder is subjected to supercritical carbon dioxide extraction, and an entrainer is added during the extraction. The weight ratio of the entrainer to the powder is 0.3:100 to obtain a solution and a residue;

[0098] S3: The residue is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com