An atmospheric odor treatment device

A treatment device and odor technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems affecting the efficiency of deodorization, easy blockage of filler pores, etc., to increase contact effect, avoid crystallization blockage, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

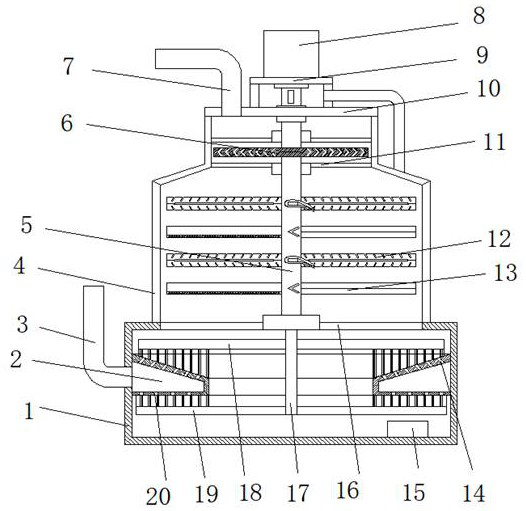

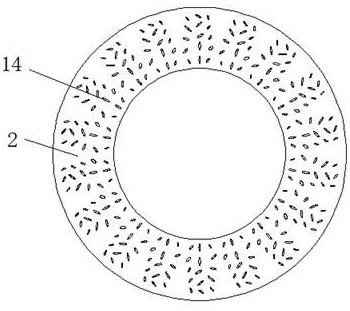

[0026] refer to Figure 1-2 and Figure 4-5 , an atmospheric odor treatment device, comprising a liquid storage tank 1, a gas scrubber 4 is fixedly installed on the top of the liquid storage tank 1, and an end cover 10 is fixedly installed on the top of the gas scrubber 4, and the side of the liquid storage tank 1 is fixed An air intake pipe 3 is installed, and an exhaust pipe 7 is fixedly installed on the top of the end cover 10, a support frame 16 is fixedly installed inside the liquid storage tank 1, and an infusion tube is installed between the support frame 16 and the end cover 10 through a sealed bearing 5. The top end cover 10 is fixedly installed with a sealing cover 9 communicating with the infusion tube 5, and the top end of the sealing cover 9 is fixedly installed with a drive motor 8 connected to the infusion tube 5, and the inner bottom of the liquid storage tank 1 is fixedly installed There is a circulation pump 15, and the outlet end of the circulation pump 15 ...

Embodiment 2

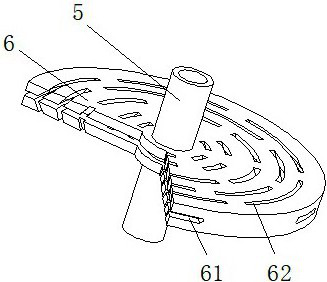

[0035] refer to Figure 1-5 , a kind of atmospheric odor treatment device, in this embodiment, with respect to embodiment 1, the surface of the liquid accumulation tray 6 is provided with a plurality of liquid accumulation grooves 62 with a V-shaped structure in cross section, and the outer side of the liquid accumulation tray 6 is provided with multiple A conduction portion 61 penetrating with the liquid accumulation tank 62 .

[0036] When this embodiment is in use, the gas entrained with the solution enters between the two layers of trapping screens 11 to trap the liquid droplets in the gas, thereby removing the liquid droplets in the air and reducing the loss of the solution. At the same time, V The liquid accumulation tank 62 and the conduction part 61 of type structure are arranged, and when the liquid drop is on the surface of the liquid accumulation plate 6, it is thrown out by centrifugal force and contacts the inner wall, and it is collected downstream to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com