Boron sol and preparation method thereof

A boron sol and sol technology, applied in the field of stable nano boron sol and preparation, can solve problems such as reported and no nano boron sol technology, and achieve the effects of good dispersion effect, easy large-scale production, and simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

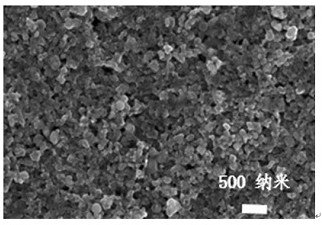

Image

Examples

Embodiment 2

[0019] Example 2: Weigh 90 grams of deionized water and 10 grams of boron powder, stir and mix evenly, add them to a zirconia ball mill jar, and add 500 grams of zirconia balls with a diameter of 8 mm, ball mill for 3 hours, and the boron solution after ball milling Disperse with an ultrasonic disperser for 2 hours, and finally centrifuge at 8000 rpm for 10 minutes to take the supernatant and prepare a uniform and stable dispersed nano-boron dispersion (boron sol).

Embodiment 3

[0020] Example 3: Weigh 70 grams of deionized water and 30 grams of boron powder, stir and mix evenly, add them to a zirconia ball mill tank, and add 500 grams of zirconia balls with a diameter of 8 mm, ball mill for 4 hours, and the boron solution after ball milling Disperse with an ultrasonic disperser for 4 hours, and finally centrifuge at 15,000 rpm for 10 minutes to take the supernatant and prepare a uniform and stable dispersed nano-boron dispersion (boron sol).

Embodiment 4

[0021] Example 4: Weigh 80 grams of deionized water and 20 grams of boron powder, stir and mix evenly, add them to a zirconia ball mill tank, and add 500 grams of zirconia balls with a diameter of 8 mm, ball mill for 4 hours, and the boron solution after ball milling Disperse with an ultrasonic disperser for 4 hours, and finally centrifuge at 20,000 rpm for 10 minutes to take the supernatant and prepare a uniform and stable dispersed nano-boron dispersion (boron sol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com