Titanium dioxide/graphene/carbon composite material, preparation method and application thereof

A carbon composite material, titanium dioxide technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of low photocatalytic efficiency, unfriendly environment, high solvent cost, etc. The effect of strong control and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

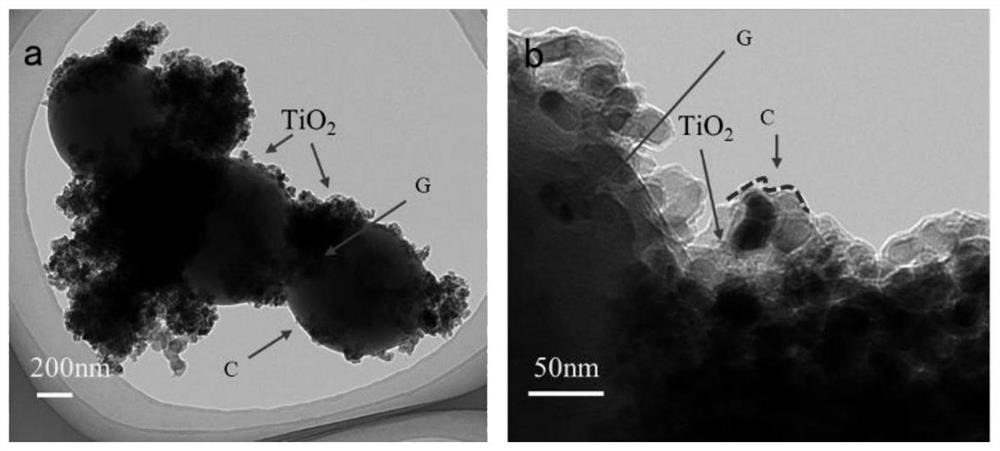

[0057] The invention provides a titanium dioxide / graphene / carbon composite material and its preparation method and application.

[0058] A method for preparing titanium dioxide / graphene / carbon composite material, prepared from raw materials including titanium dioxide, graphene, and carbon-containing compounds, said method comprising the steps of:

[0059] (1) adding raw materials other than the carbon-containing compound into a carbon-containing compound solution with a concentration of 0.05-3 mol / L, performing a hydrothermal reaction at 150-300° C. for 2-8 hours, and drying the solid to obtain a mixture after cooling;

[0060] (2) Anneal the mixture obtained in step (1) at 400-500° C. for 2-3 hours to obtain.

[0061] In the preparation method of the present invention, the titanium dioxide used may be commercially available titanium dioxide powder.

[0062] In the preparation method of the present invention, the graphene used may be commercially available graphene.

[0063] T...

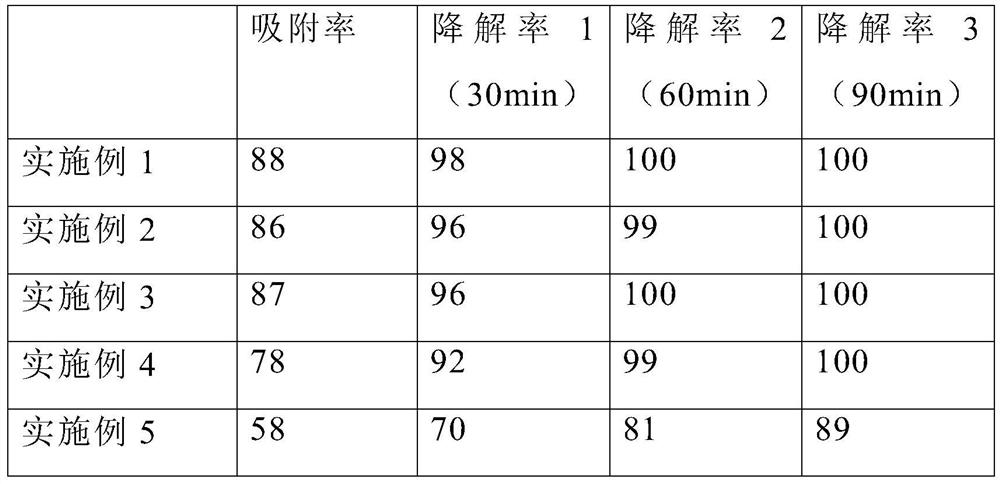

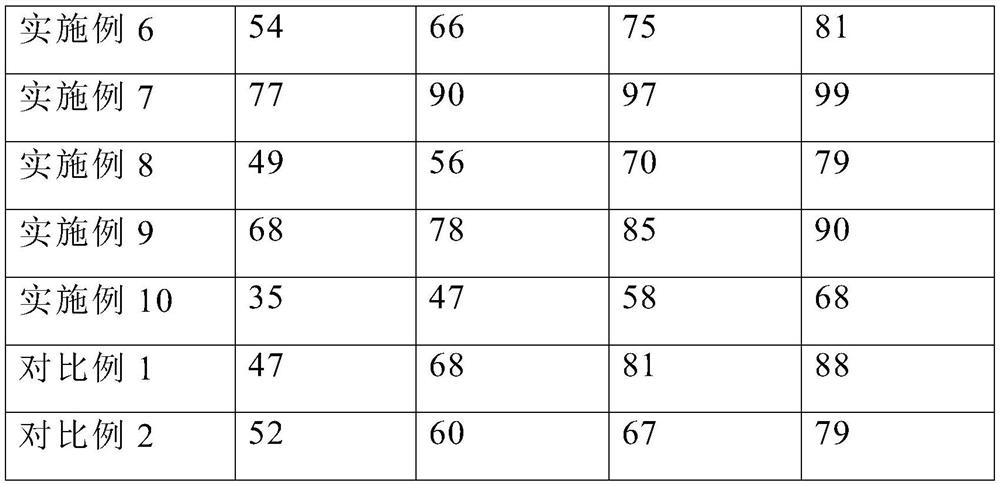

Embodiment 1

[0119] This embodiment provides a titanium dioxide / graphene / carbon composite material and a preparation method thereof, the specific steps are as follows:

[0120] 1) Weigh 10g of nanoscale titanium dioxide and 0.5g of graphene powder, grind the two to make them evenly mixed.

[0121] 2) Weigh 3.6 g of glucose, dissolve it in deionized water, and prepare a solution with a concentration of 0.1 mol / L. The powder obtained by mixing the above step (1) was added into the glucose solution, stirred for 2 hours, and the cells were ultrasonically crushed for 20 minutes, so that the solute was fully dispersed in the solution. The mixture was put into a hydrothermal reaction kettle and reacted at 180°C for 4h. After cooling, take out the mixed solution and centrifuge again (6000r / min, 10min), pour off the suspension, and repeat the centrifugation 5 times until it is washed. Dry the remaining solid at 60°C.

[0122] 3) Weighing 3g of urea and grinding and mixing with the powder obtaine...

Embodiment 2

[0127] 1) Weigh 8g of nanoscale titanium dioxide and 0.5g of graphene powder, and grind the two to make them evenly mixed.

[0128] 2) Weigh 3.6 g of glucose, dissolve it in deionized water, and prepare a solution with a concentration of 0.1 mol / L. The powder obtained by mixing the above step (1) was added into the glucose solution, stirred for 2 hours, and the cells were ultrasonically crushed for 20 minutes, so that the solute was fully dispersed in the solution. The mixture was put into a hydrothermal reaction kettle and reacted at 180°C for 4h. After cooling, take out the mixed solution and centrifuge again (5000r / min, 10min), pour off the suspension, and repeat the centrifugation 5 times until it is washed. Dry the remaining solid at 60°C.

[0129] 3) Weighing 3g of urea and grinding and mixing with the powder obtained in step (2) to obtain a mixture for later use.

[0130] 4) Put the mixture in step (3) in a ceramic crucible, put it into a tube furnace, and heat it fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com