Method for efficiently separating wood fiber material to obtain high-purity components

A wood fiber material, high-purity technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of environmental pollution, low comprehensive utilization rate, low utilization rate of wood fiber materials, etc., to broaden the scope of application and high utilization value , good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

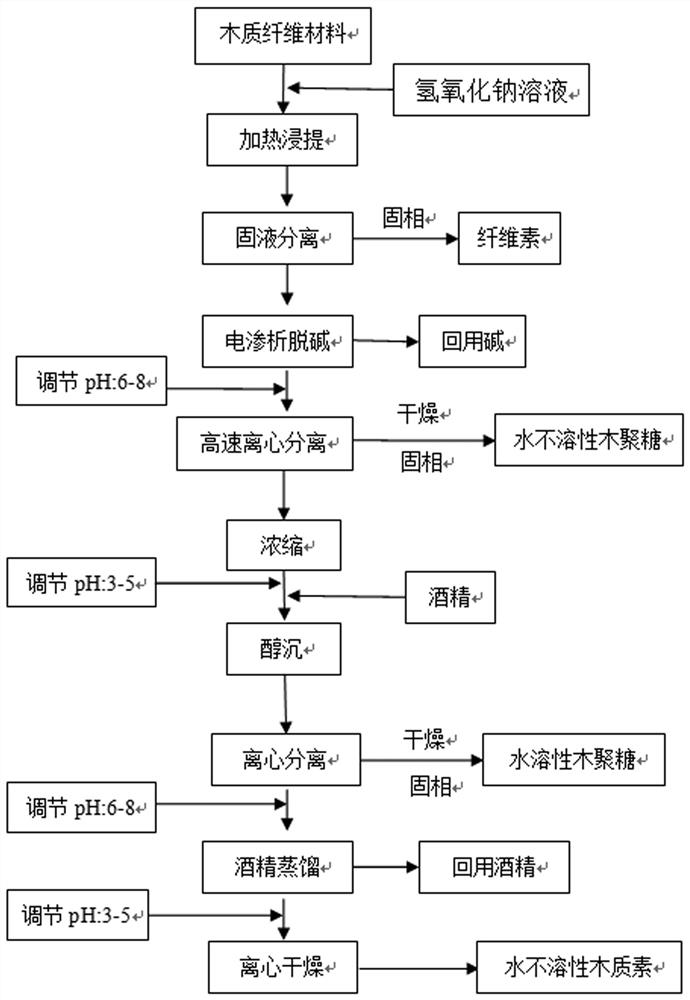

[0034] A method for efficiently separating lignocellulosic materials to obtain high-purity components, the steps are as follows:

[0035] (1) Crush the non-mildew and dry corncobs, put them into 10% sodium hydroxide solution for extraction for 3 hours, the ratio of solid to liquid is 1:10, and the extraction temperature is 90°C. After the leaching is finished, the solid-liquid separation is carried out after centrifugation with a centrifuge to obtain the solid phase and the extract; the solid phase is first washed twice with a sodium hydroxide solution with a mass concentration of 6%, and the solid-liquid separation is carried out after each washing; Combine the washing liquid and the extracting liquid to obtain a mixed solution A; then wash the solid phase with water to neutrality, and use a centrifuge to remove free liquid to obtain purified cellulose.

[0036] (2) The above mixed solution A is dealkalized with an alkali-resistant electrodialysis membrane, and the alkali in ...

Embodiment 2

[0041] A method for efficiently separating lignocellulosic materials to obtain high-purity components, the steps are as follows:

[0042] (1) After chopping, chopping and kneading the dry bamboo without mildew, put it into the sodium hydroxide solution with a mass fraction of 12% for 2 hours, the ratio of solid to liquid is 1:12, and the leaching temperature is 120°C. After the leaching, use a centrifuge to separate the solid and liquid to obtain the solid phase and the extract; wash the solid phase twice with a sodium hydroxide solution with a mass concentration of 6%, and perform a solid phase after each washing. Liquid separation; combining the washing liquid and the extracting liquid to obtain a mixed solution A; then washing the solid phase with water to neutrality, and using a centrifuge to remove free liquid to obtain purified cellulose.

[0043] (2) The above mixed solution A is dealkalized with an alkali-resistant electrodialysis membrane, and the alkali in the soluti...

Embodiment 3

[0048] A method for efficiently separating lignocellulosic materials to obtain high-purity components, the steps are as follows:

[0049] (1) Grind the non-mildew and dried bagasse into 8% potassium hydroxide solution for extraction for 2 hours, the ratio of solid to liquid is 1:10, and the extraction temperature is 100°C. After the leaching is finished, the solid-liquid separation is carried out after being centrifuged by a centrifuge to obtain a solid phase and an extract; the solid phase is first washed twice with a potassium hydroxide solution with a mass concentration of 6%, and the solid-liquid separation is carried out after each washing; Combine the washing liquid and the extracting liquid to obtain a mixed solution A; then wash the solid phase with water to neutrality, and use a centrifuge to remove free liquid to obtain purified cellulose.

[0050] (2) The above mixed solution A is dealkalized with an alkali-resistant electrodialysis membrane, and the alkali in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com