Efficient preparation method of high-molecular-weight polymyrcene with high 1,4-structure content

A high-molecular-weight, myrcene technology is applied in the field of efficient preparation of high-molecular-weight polymyrcene, can solve the problems of low catalytic activity, large amount of catalyst and high polymerization cost, and achieves the effects of high catalytic activity, high molecular weight and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

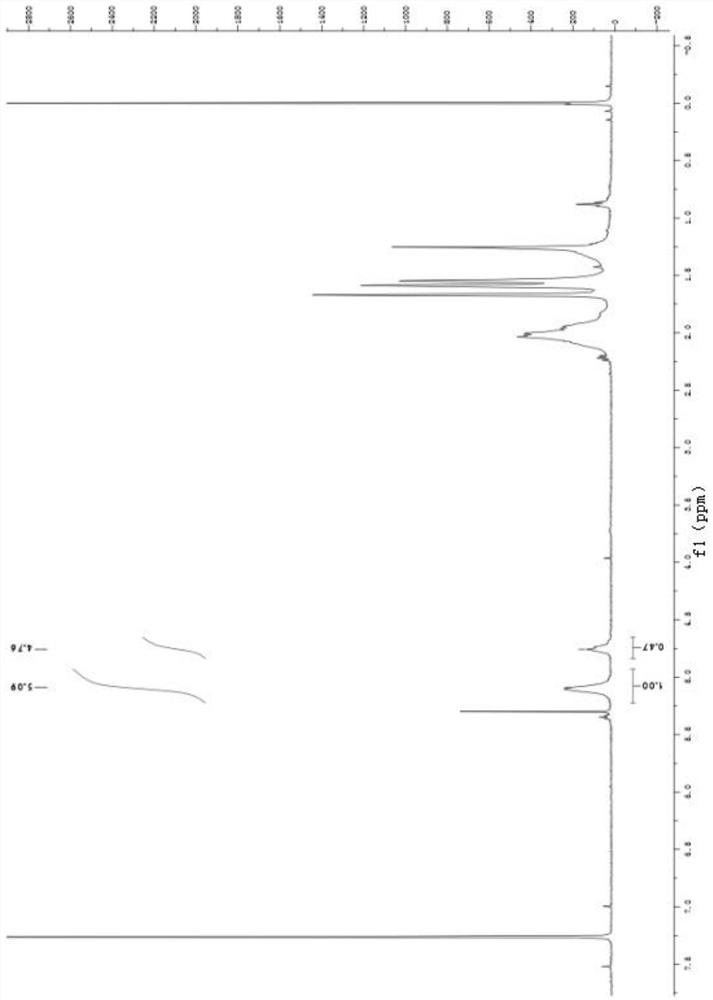

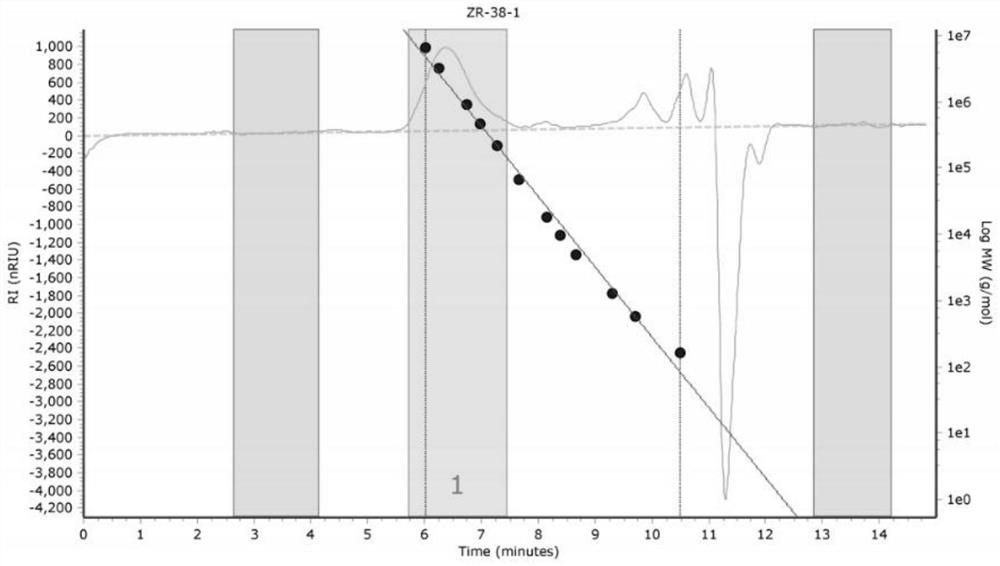

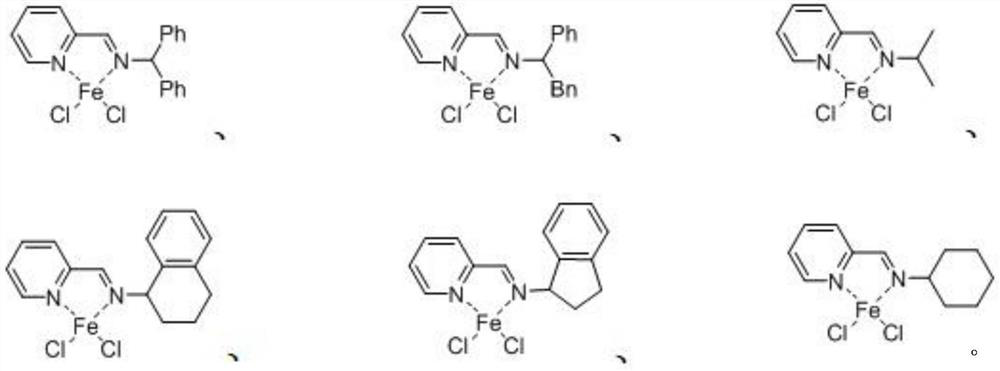

[0034] Specific embodiment 1: A high-efficiency preparation method of high-molecular-weight polymyrcene with high 1,4-structure content in this embodiment is carried out according to the following steps:

[0035] Take a Schlenk bottle, add 45mL of toluene, cocatalyst MAO (5mmol, 500equiv, 3.33mL), myrcene monomer (50mmol, 5000equiv, 8.6mL), and pyridinimine iron complex in sequence under the condition of anhydrous and oxygen-free argon. Material 1 (10μmol, 1equiv, 4.0mg), under the condition of stirring, polymerized at 25°C for 30min, then added 20mL of a mixed solution of hydrochloric acid and methanol and 5mL of anti-aging agent to quench the reaction, and poured off the clear liquid. The polymer was washed with ethanol three times, and the obtained polymer was vacuum-dried at 40° C. to constant weight to obtain polymyrcene; the volume ratio of methanol to concentrated hydrochloric acid in the mixed solution of hydrochloric acid and methanol was 50:1.

[0036] The yield of t...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amount of co-catalyst MAO is (2.5 mmol, 250 equiv, 1.67 mL). Other steps and parameters are the same as those in the first embodiment.

[0038] The yield of this embodiment is 98%, and the microstructural selectivity of the polymer is: 62% 1,4-polymyrcene and 38% 3,4-polymyrcene, M n (Number average molecular weight, g / mol) was 1.57 million, and PDI (molecular weight distribution) was 1.8.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is different from Embodiment 1 in that the amount of toluene is 90 mL, and the amount of myrcene monomer is (100 mmol, 10000 equiv, 17.2 mL). Other steps and parameters are the same as those in the first embodiment.

[0040] The yield of this embodiment is >99%, and the microstructural selectivity of the polymer is: 65% 1,4-polymyrcene and 35% 3,4-polymyrcene, M n (Number average molecular weight, g / mol) was 1.38 million, and PDI (molecular weight distribution) was 2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com