Carbon nanotube master batch and preparation method and application thereof

A carbon nanotube and masterbatch technology, applied in the field of carbon nanotube masterbatch and its preparation, can solve the problems of unstable production, fluctuation of material conductivity, dust pollution, etc., and achieves convenient production method, high degree of design freedom, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

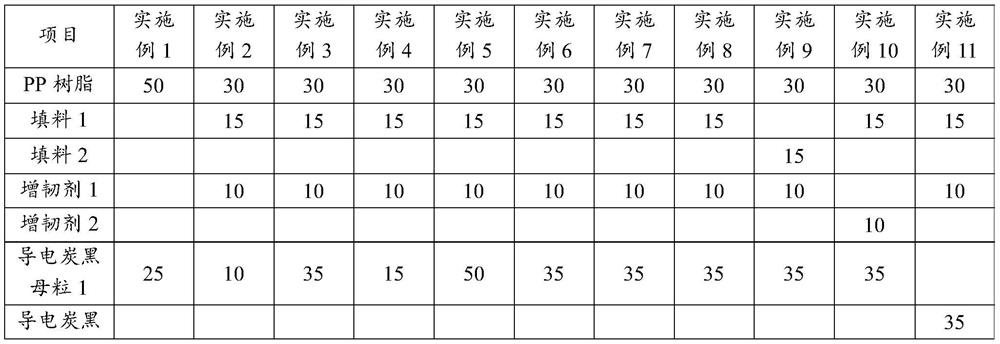

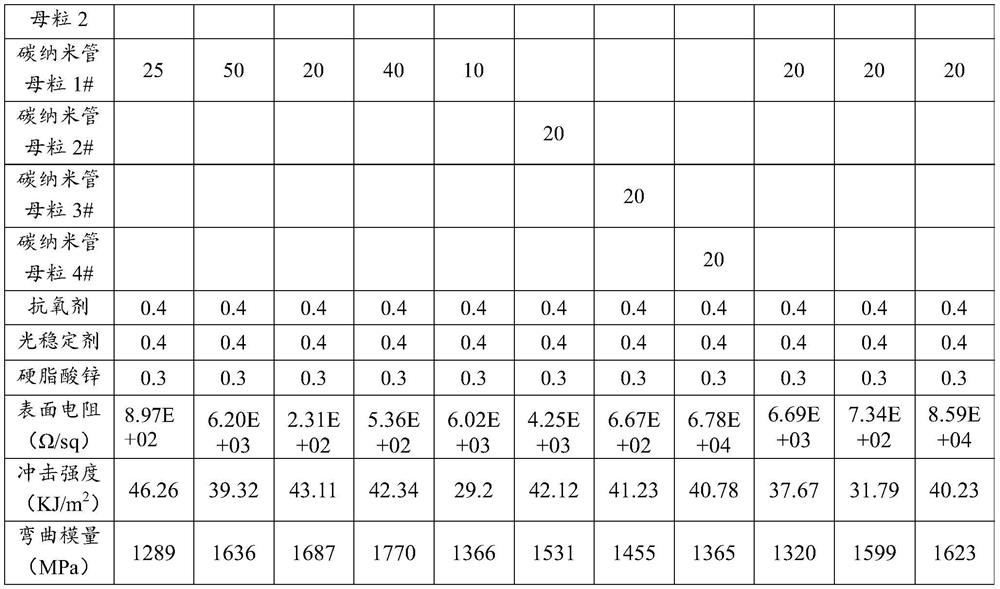

[0035] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. The following examples are only typical examples of the present invention, and the protection scope of the present invention is not limited thereto. In the following examples and comparative examples, the electrical conductivity test method is: the surface resistance of the material is tested according to ASTM D-4496 and D-257 standards; the test standard of impact strength is ISO 527; the test of flexural modulus is expressed as ISO 178 .

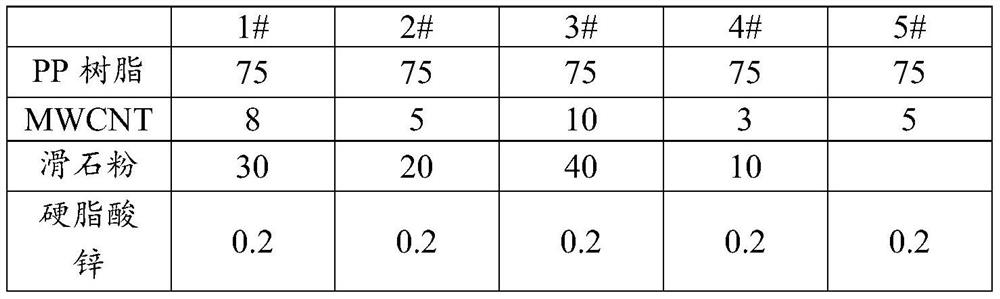

[0036] The main representative material used in embodiment and comparative example is as follows:

[0037] PP resin: polypropylene copolymer, with a melt mass flow rate of 40g / 10min at 230°C and a load of 2.16Kg, Sinopec Maoming;

[0038] MWCNT: tube diameter 8-15nm, length 10-70um, LG Chem;

[0039] Filler 1 (talcum powder): particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com