Mining heating system based on graphene carbon fiber electrothermal film

A carbon fiber and heating system technology, applied in ohmic resistance heating, general control system, electric heating device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

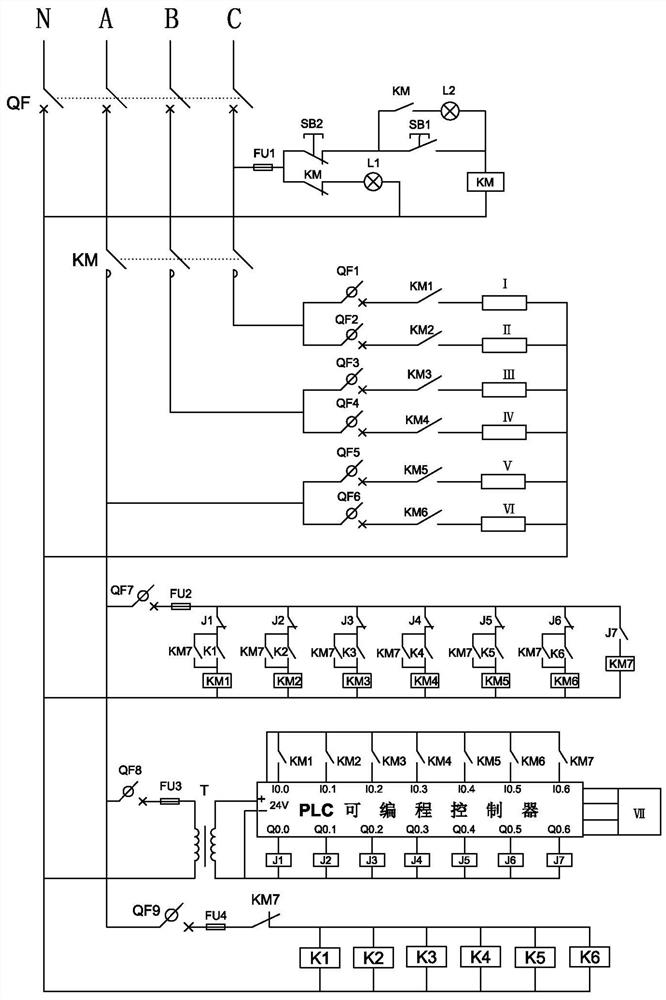

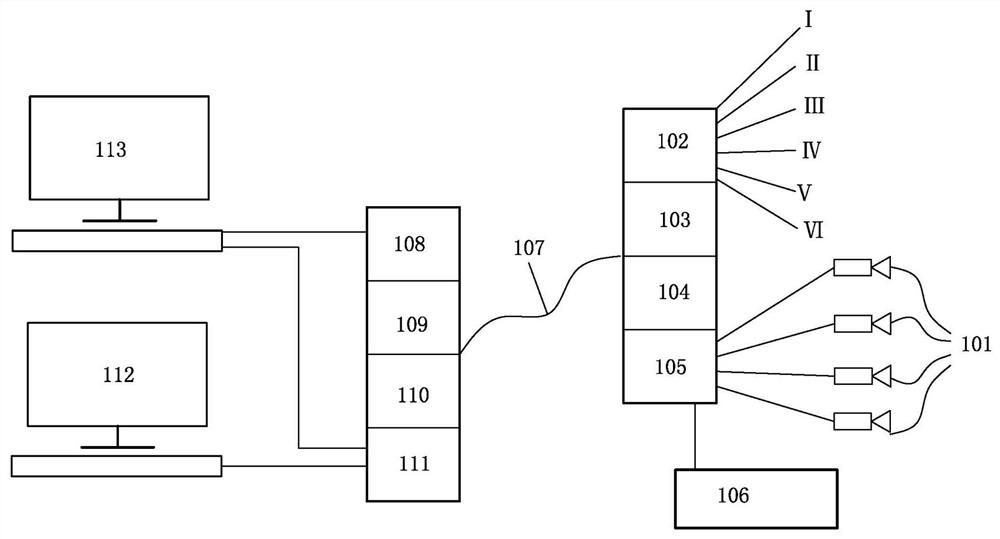

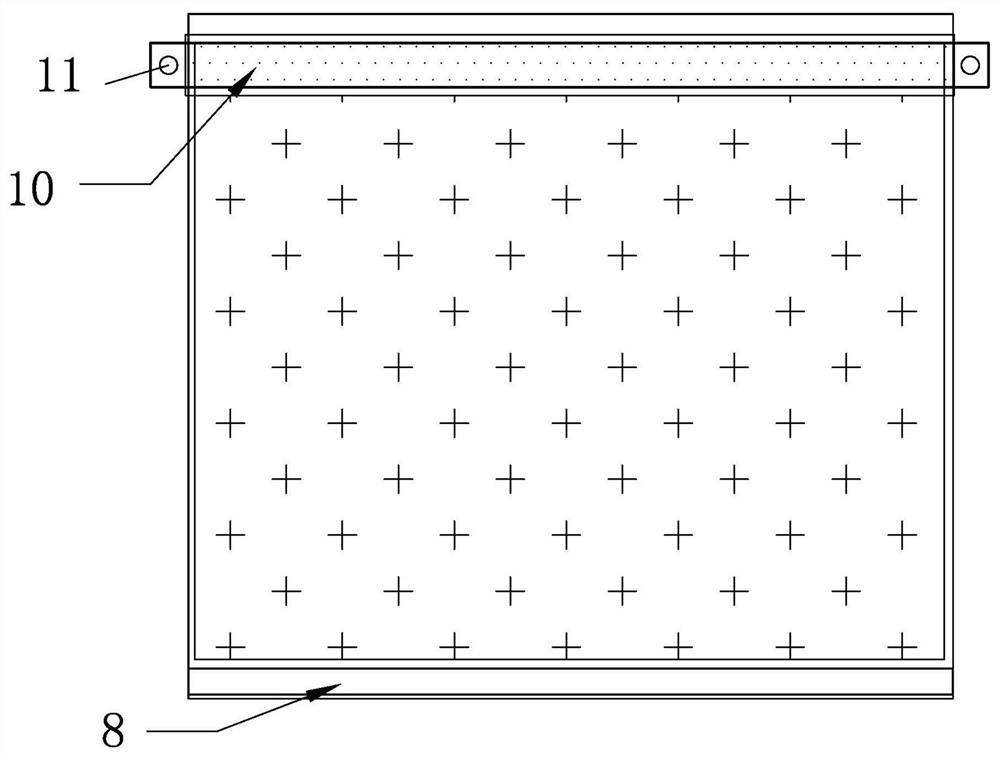

[0027] A mine heating system based on graphene carbon fiber electrothermal film: such as Figure 1 to Figure 5 As shown, including electrical control system, monitoring system and electric heating film fixed protection device;

[0028] 1. The electrical control system is a dual temperature control system, including a power supply circuit, a load circuit, a dual control circuit, a PLC control circuit and a K-type temperature controller circuit; the number of loads is set to n, which are respectively load I and load II ... load n;

[0029] Power supply circuit: including the main leakage protection circuit breaker QF and the main contactor KM, the normally open contact of the main contactor KM is connected in series with the lamp L2 and then connected in parallel with the button switch SB1, the formed parallel circuit is connected with the coil and the button of the main contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com