Semiconductor device forming method and semiconductor device

A semiconductor and device technology, which is applied to the formation method of semiconductor devices and the field of semiconductor devices, can solve problems such as poor adhesion between electrodes and packaging layers, programming interference of memory cells, and changes in the composition of phase change materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] figure 2 A schematic diagram of the implementation flow of the method for forming a semiconductor device provided in the embodiment of the present application, as shown in figure 2 As shown, the method includes the following steps:

[0123] Step S201, forming a semiconductor stack structure.

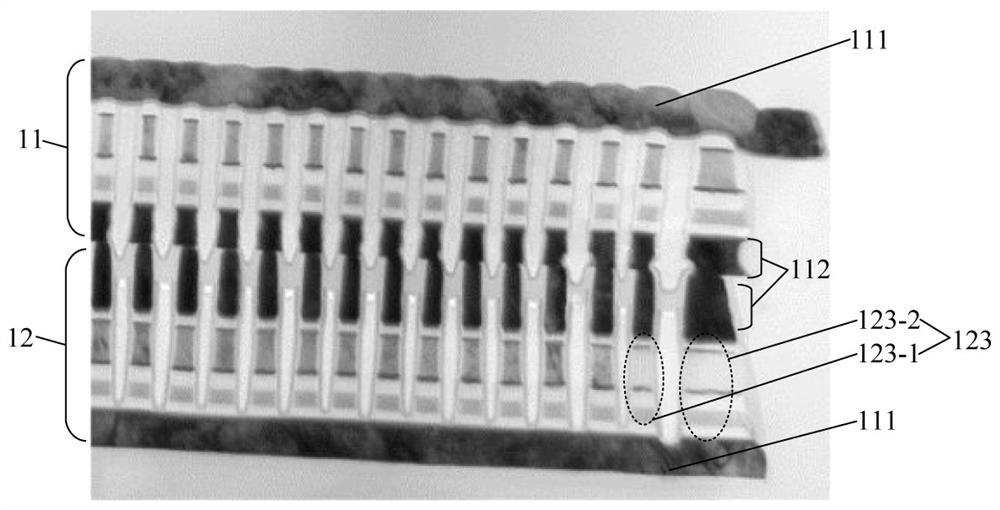

[0124] Figure 3A A schematic diagram of a three-dimensional structure of a semiconductor stack structure provided in an embodiment of the present application, Figure 3B A schematic cross-sectional structure diagram of a semiconductor stack structure provided in an embodiment of the present application, combined with Figure 3A and 3B As shown, a semiconductor stack structure 31 is deposited on a substrate 30 .

[0125] Here, the substrate 30 is located at the bottom of the entire structure, and the material of the substrate can be selected from silicon (Si), silicon-germanium alloy (SiGe), silicon carbide (SiC), aluminum oxide (Al 2 o 3 ), aluminum nitride (AlN), zinc o...

Embodiment 2

[0137] Figure 4 A schematic diagram of the implementation flow of the method for forming a semiconductor device provided in the embodiment of the present application, as shown in Figure 4 As shown, the method includes the following steps:

[0138] Step S401 , stacking and forming an intermediate electrode layer, a phase change material layer and a top electrode layer sequentially from bottom to top to form a semiconductor stack structure.

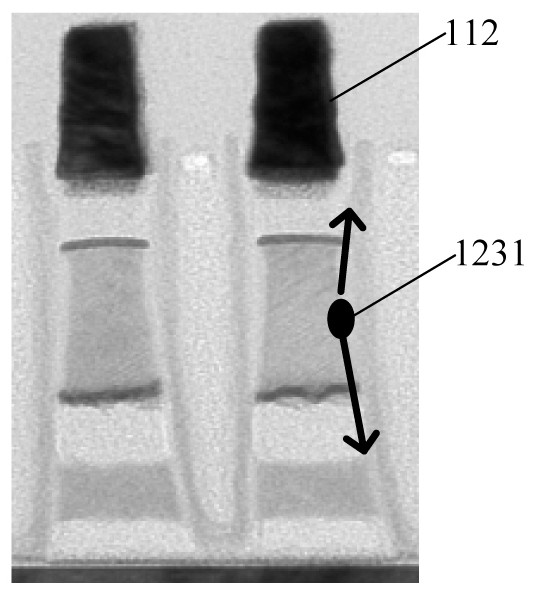

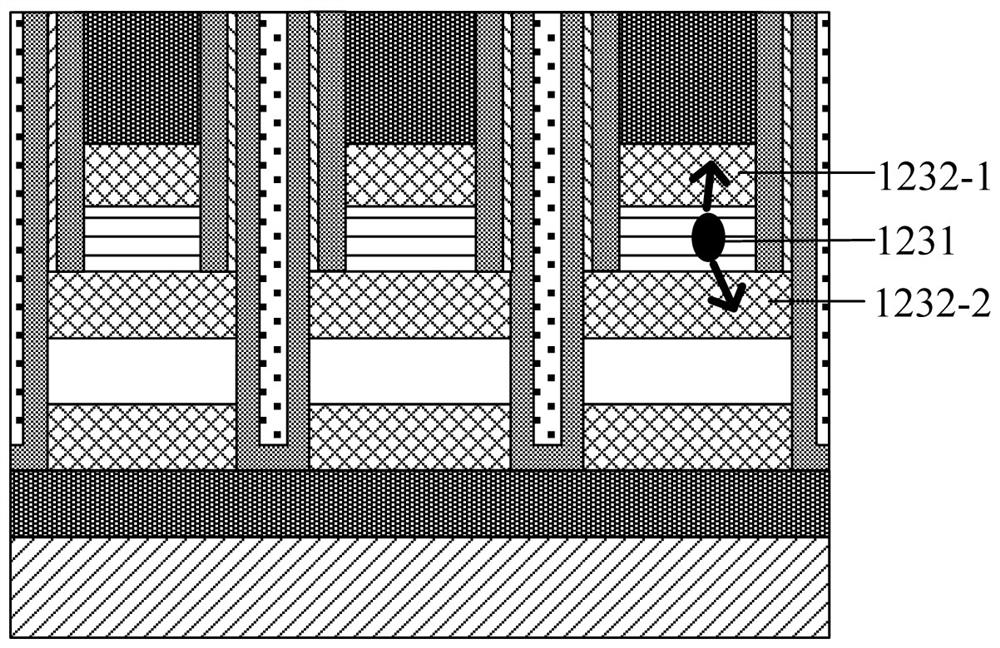

[0139] Figure 5A A schematic diagram of a three-dimensional structure of a semiconductor stack structure provided in an embodiment of the present application, Figure 5B A schematic cross-sectional structure diagram of a semiconductor stack structure provided in an embodiment of the present application, combined with Figure 5A and 5B As shown, the semiconductor stack structure 50 at least includes: a top electrode layer 502-1, a phase change material layer 503 and a middle electrode layer 502-2. Wherein, the top electrode layer 502...

Embodiment 3

[0164] Figure 6 A schematic diagram of the implementation flow of the method for forming a semiconductor device provided in the embodiment of the present application, as shown in Figure 6 As shown, the method includes the following steps:

[0165] Step S601, forming a semiconductor stack structure.

[0166] In the embodiment of the present application, the formation of the semiconductor stack structure may be achieved through the following steps:

[0167] Step S6011, stacking and forming an intermediate electrode layer, a phase change material layer and a top electrode layer sequentially from bottom to top.

[0168] Step S6012, forming a gate layer, a bottom electrode layer and a first address line layer under the middle electrode layer.

[0169] Here, the semiconductor stack structure is a stack structure with a certain number of layers formed on the substrate, Figure 7A A schematic diagram of a three-dimensional structure of a semiconductor stack structure provided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com