Large-pore-volume high-adsorption silicon dioxide additive and preparation method thereof

A silicon dioxide, high adsorption technology, applied in chemical instruments and methods, additional food elements, inorganic chemistry, etc., can solve adsorption, stability, anti-caking and poor fluidity, flow performance and anti-caking performance. , poor adsorption performance of silica particles, etc., to achieve good stability, high adsorption performance, and the effect of increasing pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

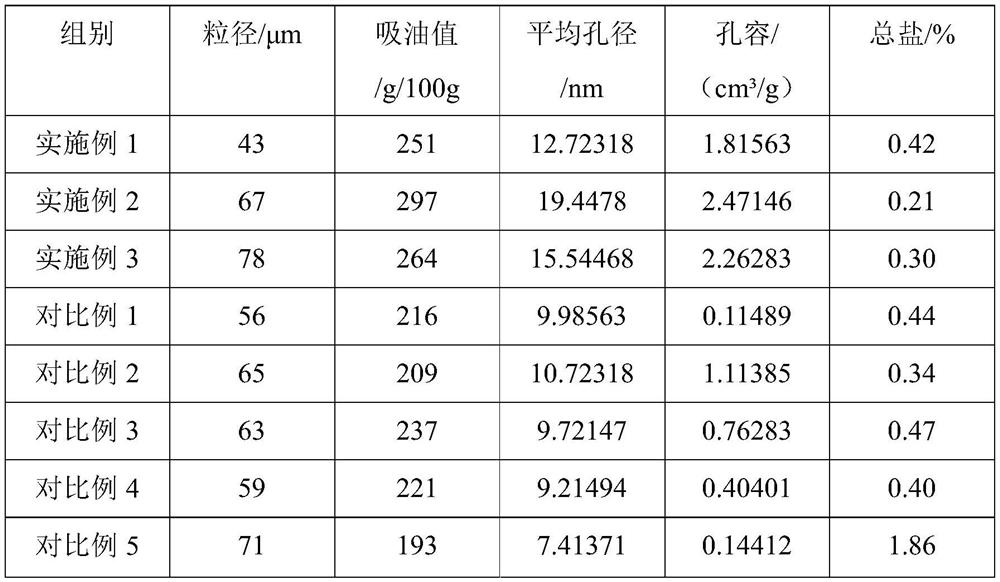

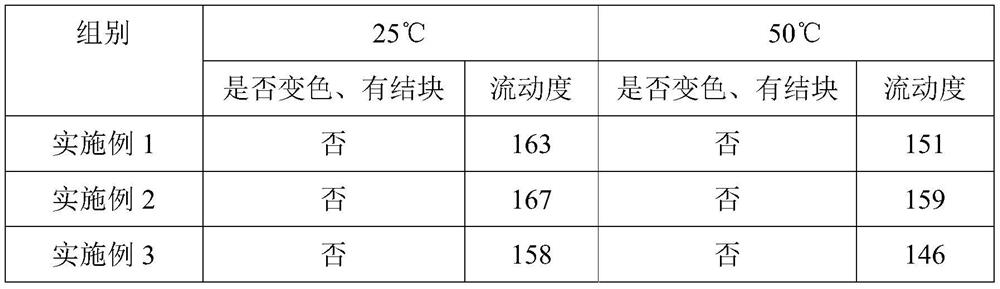

Examples

Embodiment 1

[0028] Example 1, a large pore volume high adsorption silica additive and its preparation method

[0029] The preparation method of described large pore volume high adsorption silica additive comprises the following steps:

[0030] S1, configuration molar concentration is the sodium silicate solution of 0.45mol / L and the dilute sulfuric acid solution that molar concentration is 1mol / L;

[0031] S2, add 10m in reaction tank 3 The sodium silicate solution prepared in step S1 is heated up to 85°C, the stirring device is turned on and the stirring frequency is set to 25Hz, and the anionic surfactant K12 surfactant is added, and the mass of the K12 surfactant is 0.005% of the mass of the sodium silicate solution. %, continue to stir for 5min;

[0032] S3, continue to add the dilute sulfuric acid solution that step S1 makes in the reaction tank, the adding speed of dilute sulfuric acid is 2.0m 3 / h, when the emulsification point appears instantly in the reaction system and the pH...

Embodiment 2

[0034] Example 2, a large pore volume high adsorption silica additive and its preparation method

[0035] The preparation method of described large pore volume high adsorption silica additive comprises the following steps:

[0036] S1, configuration molar concentration is the sodium silicate solution of 0.58mol / L and the dilute sulfuric acid solution that molar concentration is 1.45mol / L;

[0037] S2, add 10m in reaction tank 3 The sodium silicate solution prepared in step S1 is heated up to 88° C., the stirring device is turned on and the stirring frequency is set to 30 Hz, and the anionic surfactant K12 surfactant is added, and the mass of the K12 surfactant is 0.01% of the mass of the sodium silicate solution. %, continue to stir for 5min;

[0038]S3, continue to add the dilute sulfuric acid solution that step S1 makes in the reaction tank, the adding speed of dilute sulfuric acid is 2.3m 3 / h, when the emulsification point appears instantly in the reaction system and th...

Embodiment 3

[0040] Example 3, a large pore volume high adsorption silica additive and its preparation method

[0041] The preparation method of described large pore volume high adsorption silica additive comprises the following steps:

[0042] S1, configuration molar concentration is the sodium silicate solution of 0.75mol / L and the dilute sulfuric acid solution that molar concentration is 2mol / L;

[0043] S2, add 10m in reaction tank 3 The sodium silicate solution prepared in step S1 is heated up to 90° C., the stirring device is turned on and the stirring frequency is set to 35 Hz, and the anionic surfactant K12 surfactant is added, and the mass of the K12 surfactant is 0.015% of the mass of the sodium silicate solution. %, continue to stir for 5min;

[0044] S3, continue to add the dilute sulfuric acid solution that step S1 makes in the reaction tank, the adding speed of dilute sulfuric acid is 2.5m 3 / h, when the emulsification point appears instantly in the reaction system, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com