Microbial fuel cell wastewater treatment system

A wastewater treatment system and fuel cell technology, which is applied in the fields of biochemical fuel cells, biological water/sewage treatment, textile industry wastewater treatment, etc. The effect of mass transfer efficiency, saving membrane cost and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

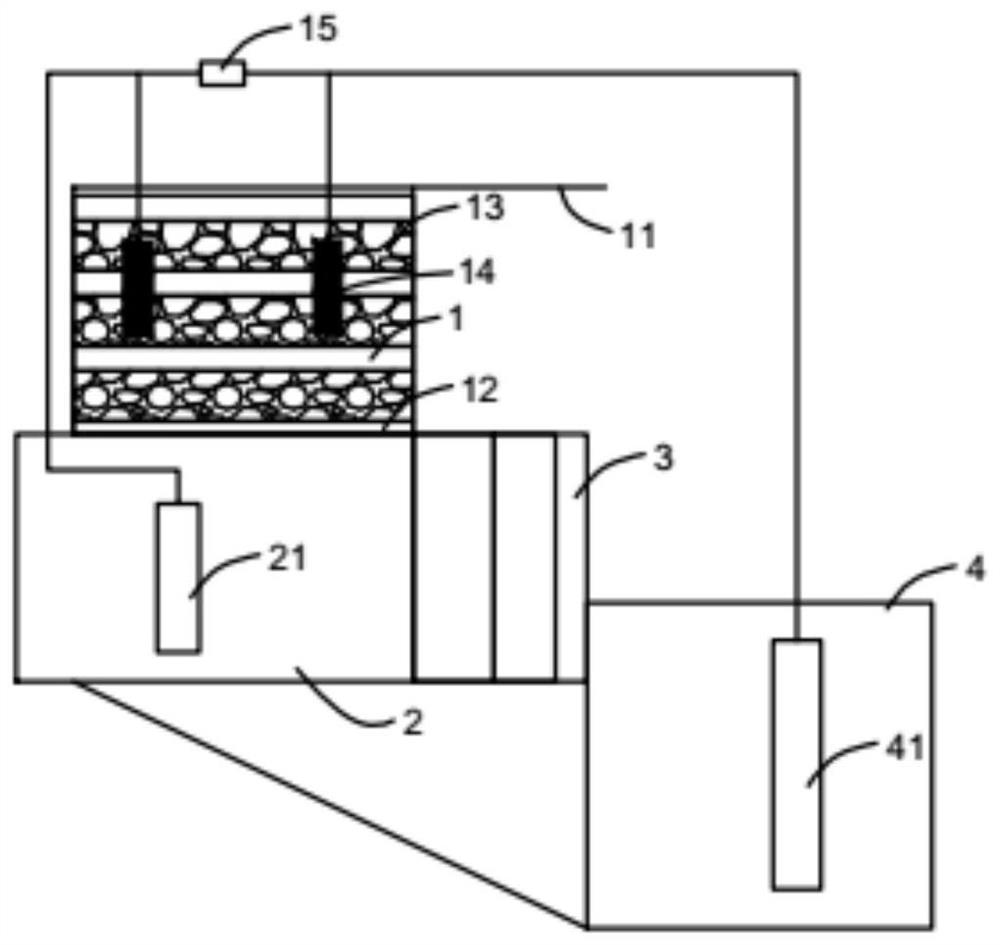

[0028] like figure 1 Shown, a kind of microbial fuel cell waste water treatment system comprises: Comprising: iron-carbon pool 1, cathode room 2, iron-carbon reduction pool 3, anode room 4, described iron-carbon pool 1 top is provided with water inlet pipe 11, and described iron-carbon pool 1 An aeration device 12 is arranged at the bottom of the carbon pool 1, and a multi-layer iron-carbon filler layer 13 is arranged in the iron-carbon pool, and a gap is arranged between the iron-carbon filler layers; the iron-carbon pool 1 communicates with the cathode chamber 2, and the A cathode 21 is arranged in the cathode chamber 2, and the cathode chamber 2 communicates with the iron-carbon reduction pool 3, and an iron-carbon filler is arranged in the iron-carbon reduction pool 3, and is added to the iron-carbon reduction pool during the wastewater treatment process. Reductant, the iron-carbon reduction pool 3 communicates with the anode chamber 4, an anode 41 is set in the anode cham...

Embodiment 2

[0032] A printing and dyeing wastewater CODcr is 890mg / L, BOD5 is 256mg / L.

[0033] The invention discloses a microbial fuel cell waste water treatment system, comprising: an iron-carbon pool 1, a cathode chamber 2, an iron-carbon reduction pool 3, and an anode chamber 4; a water inlet pipe 11 is arranged above the iron-carbon pool 1; An aeration device 12 is arranged at the bottom of the pool 1, and a multi-layer iron-carbon filler layer 13 is arranged in the iron-carbon pool, and a gap is arranged between the iron-carbon filler layers; the iron-carbon pool 1 communicates with the cathode chamber 2, and the cathode A cathode 21 is arranged in the chamber 2, and the cathode chamber 2 is connected to the iron-carbon reduction pool 3, and an iron-carbon filler is arranged in the iron-carbon reduction pool 3, and a reduction agent is added to the iron-carbon reduction pool during the wastewater treatment process. agent, the iron-carbon reduction pool 3 communicates with the anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com