Metallocene catalyst for synthesizing polyolefin elastomer, preparation method and application

A technology of metallocene catalysts and polyolefin elastomers, applied in the field of catalysts, can solve the problems of high consumption of cocatalyst MAO and high cost of catalyst preparation, and achieve the effects of high ethylene content, good particle shape and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

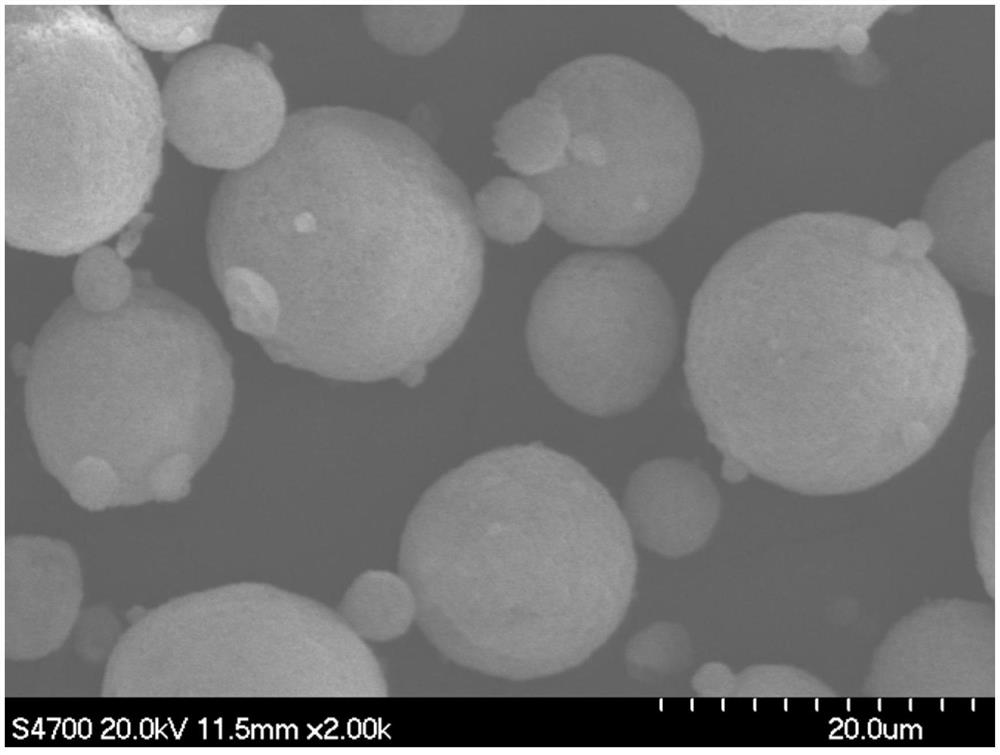

[0035] The preparation method of spherical montmorillonite carrier in embodiment 1-3 is:

[0036] (1) Acidification treatment

[0037] Take 150g of montmorillonite, disperse it in 500mL of deionized water, stir for 1h, then add 1000mL of 0.75M hydrochloric acid solution, and stir at 80°C for 24h. The acidified montmorillonite was washed with deionized water to pH = 7 (adding AgNO 3 After the solution, the washing solution has no white precipitate). After drying at 100°C, grind and sieve to 200 mesh. The montmorillonite that had been sieved to remove coarse particles was dried at 100° C. for 2 hours, and then dried under vacuum for 2 hours, cooled to room temperature under nitrogen protection, and packaged for use.

[0038] (2) High shear dispersion treatment

[0039] Get 50g of montmorillonite obtained after the acidification treatment in step (1), disperse it in 200mL deionized water, and process it with a high-speed disperser (Krupp SupratonTM type S200) at normal temper...

Embodiment 1

[0054] A preparation method and application of a metallocene catalyst for synthesizing polyolefin elastomers:

[0055] (1) Catalyst loading

[0056] The spherical montmorillonite carrier was further vacuum-dried at 150°C for 4 hours, and the metallocene compound was supported by the following method to prepare a supported catalyst:

[0057] Under the protection of nitrogen, accurately weigh 10 g of the treated spherical montmorillonite carrier and transfer it to a glass reactor fully replaced by nitrogen, add 70 mL of dewatered and refined toluene; stir to disperse evenly, add 5 mL of methyl aluminum oxide alkane (1.5M toluene solution), stirred at 20°C for 20min to obtain a pretreated montmorillonite carrier;

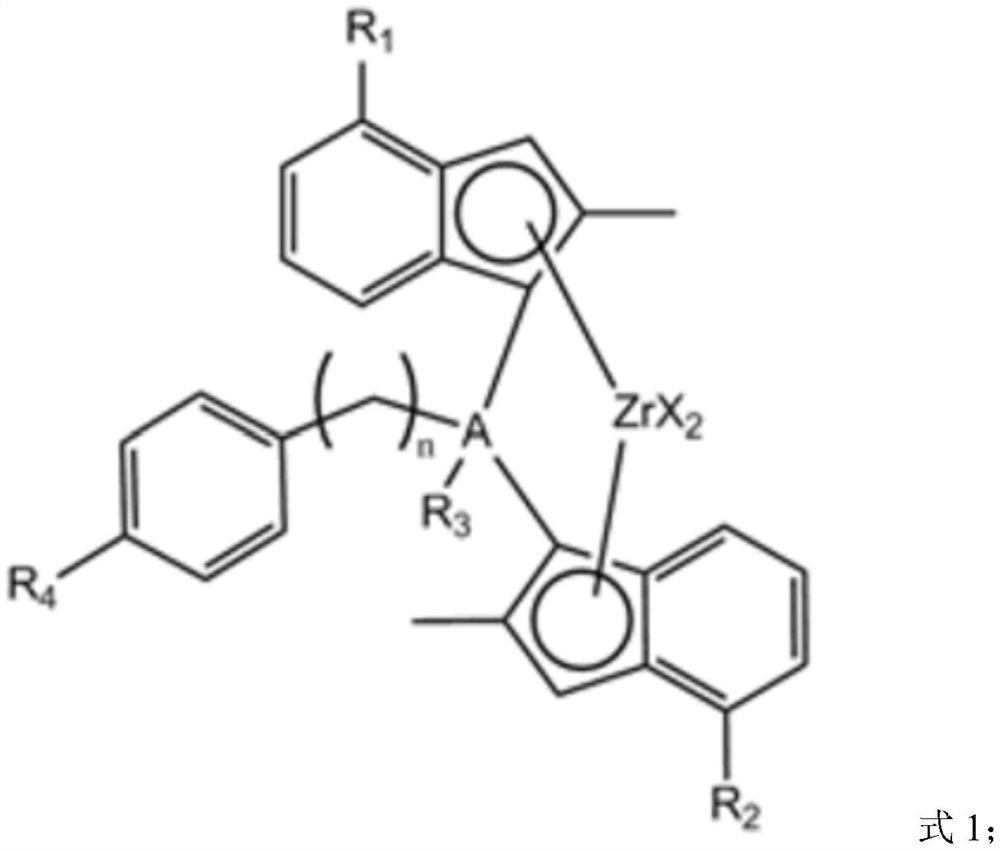

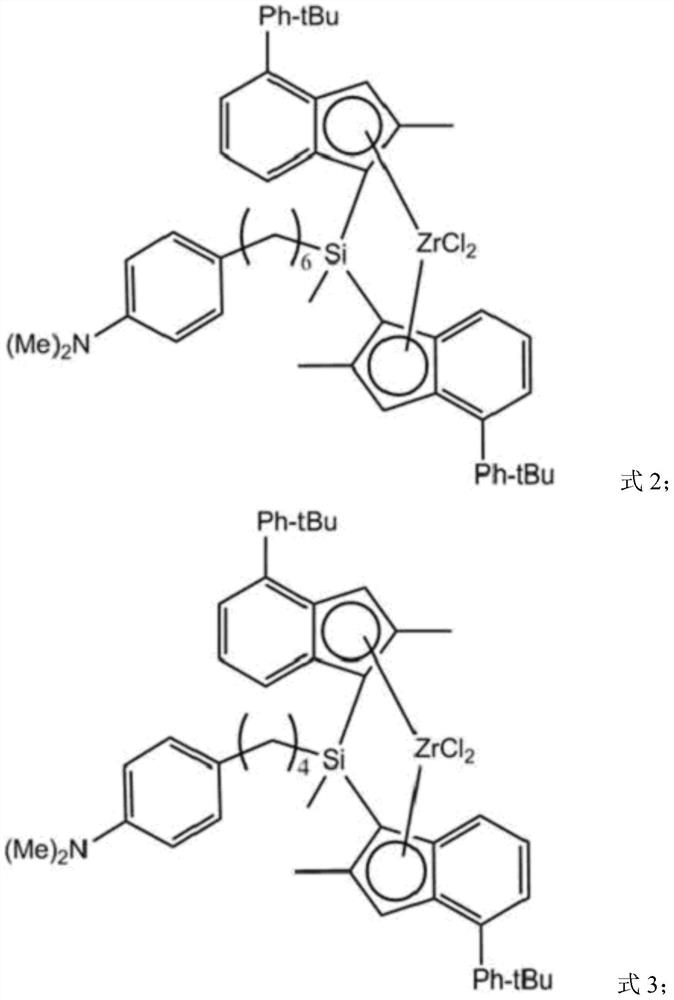

[0058] Under nitrogen protection, accurately weigh 150 mg of the metallocene compound [4-(6-(bis(4-(4-(tert-butyl)phenyl)-2-methyl-1H-inden-1-yl) synthesized above) (Methyl)silyl)hexyl)-N,N-dimethylaniline]zirconium dichloride, transfer to a glass reactor fully repla...

Embodiment 2

[0063] A preparation method and application of a metallocene catalyst for synthesizing polyolefin elastomers:

[0064] (1) Catalyst loading

[0065] The spherical montmorillonite carrier was further vacuum-dried at 150°C for 4 hours, and the metallocene compound was supported by the following method to prepare a supported catalyst:

[0066] Under the protection of nitrogen, accurately weigh 10 g of the treated spherical montmorillonite carrier and transfer it to a glass reactor fully replaced by nitrogen, add 80 mL of dewatered and refined toluene; stir to disperse evenly.

[0067]Under nitrogen protection, accurately weigh 150 mg of the metallocene compound [4-(6-(bis(4-(4-(tert-butyl)phenyl)-2-methyl-1H-inden-1-yl) synthesized above) (Methyl)silyl)hexyl)-N,N-dimethylaniline]zirconium dichloride, transfer to a glass reactor fully replaced by nitrogen, add 30mL of toluene purified by dehydration; stir to dissolve After completion, 2 mL of methylaluminoxane (1.5 M solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com