Glass fiber reinforced PC material as well as preparation method and application thereof

A glass fiber and toughening agent technology, which is applied in the field of glass fiber reinforced PC materials and its preparation, can solve problems such as cold cracking, thermal deformation of profiles, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

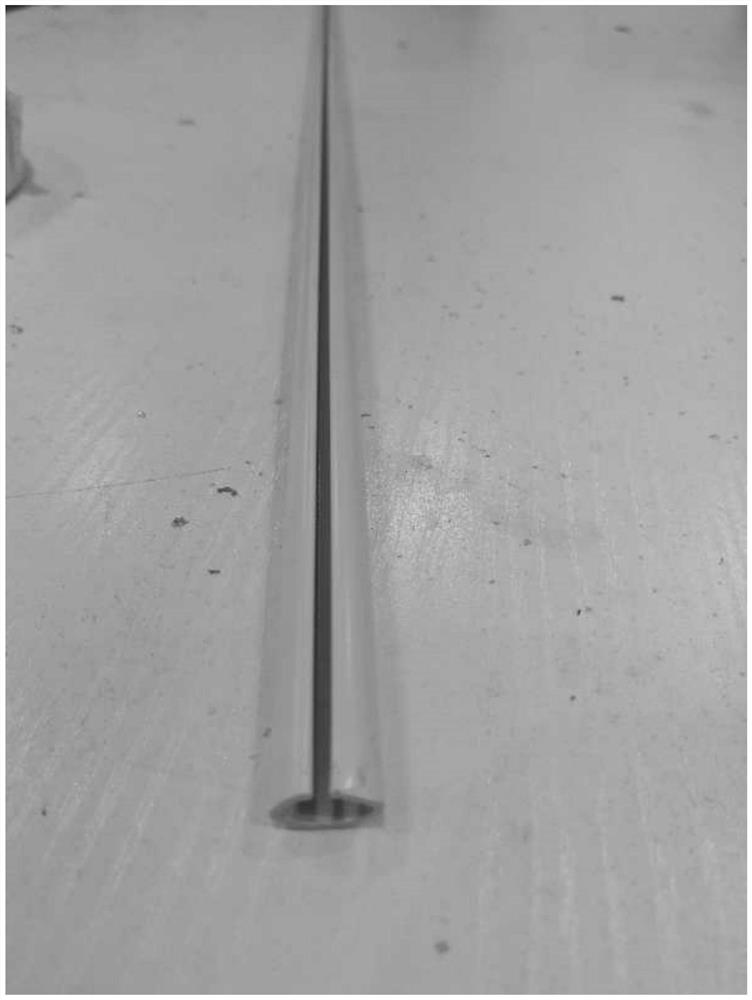

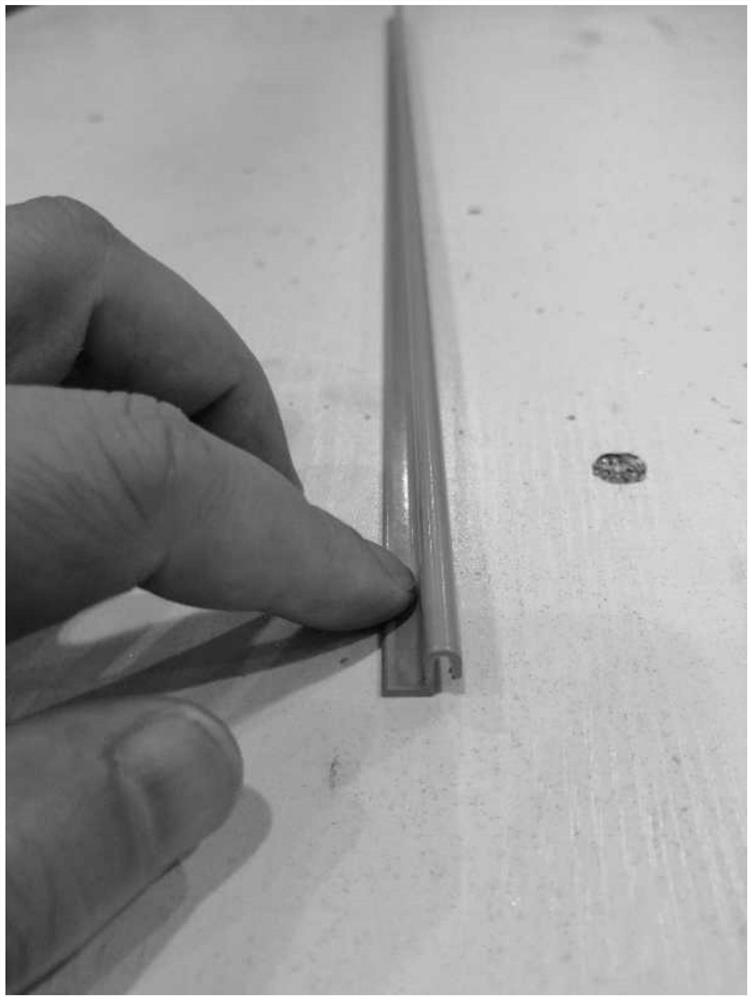

Image

Examples

preparation example Construction

[0047] A preparation method of glass fiber reinforced PC material, comprising:

[0048] Mixing steps: Weigh PC resin, glass fiber, talcum powder, titanium dioxide, dispersant, anti-UV agent, antioxidant, toner, matting agent, fusion agent, toughening agent respectively according to the formula ratio, and then mix them Homogeneously, a mixture is obtained;

[0049] Granulation step: put the mixture into a twin-screw extruder, and sequentially go through the steps of extrusion, cooling, granulation and drying to obtain dry granules.

[0050] As a preferred embodiment, in the granulation step, the temperature of the twin-screw extruder is set at 220-280°C.

[0051] As a preferred embodiment, after the granulation step is completed, a profile preparation step is also included: put the dry granules into the extruder for melting, the heating temperature is 220-280°C, the temperature of each zone of the screw is lowered in turn, and extruded through the die, and then After shaping,...

Embodiment 1

[0055] A glass fiber reinforced PC material, prepared from the following components by mass percentage: PC resin 70%, glass fiber 12.03%, talcum powder 5%, titanium dioxide 6%, dispersant 0.15%, anti-UV 0.7% agent, 0.5% antioxidant, 0.12% toner, 1% matting agent, 1.5% fusion agent, 3% toughening agent.

[0056] A preparation method of glass fiber reinforced PC material, comprising:

[0057] Mixing steps: Weigh PC resin, glass fiber, talcum powder, titanium dioxide, dispersant, anti-UV agent, antioxidant, toner, matting agent, fusion agent, toughening agent respectively according to the formula ratio, and then mix them Homogenize to obtain a mixture.

[0058] Granulation step: put the mixture into a twin-screw extruder, and then go through the steps of extrusion, cooling, pelletizing and drying in sequence to obtain dry granules. The temperature of the twin-screw extruder is set at 220-280°C.

[0059] Profile preparation steps: put the dry granules into the extruder for melti...

Embodiment 2

[0061] A glass fiber reinforced PC material, prepared from the following components by mass percentage: PC resin 72.13%, glass fiber 10%, talcum powder 5%, titanium dioxide 6%, dispersant 0.15%, anti-UV 0.6% agent, 0.5% antioxidant, 0.12% toner, 1% matting agent, 1.5% fusion agent, 3% toughening agent.

[0062] A preparation method of glass fiber reinforced PC material, comprising:

[0063] Mixing steps: Weigh PC resin, glass fiber, talcum powder, titanium dioxide, dispersant, anti-UV agent, antioxidant, toner, matting agent, fusion agent, toughening agent respectively according to the formula ratio, and then mix them Homogenize to obtain a mixture.

[0064] Granulation step: put the mixture into a twin-screw extruder, and then go through the steps of extrusion, cooling, pelletizing and drying in sequence to obtain dry granules. The temperature of the twin-screw extruder is set at 220-280°C.

[0065] Profile preparation steps: put the dry granules into the extruder for melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com