Carbon dioxide foam fracturing system foaming agent as well as preparation method and application thereof

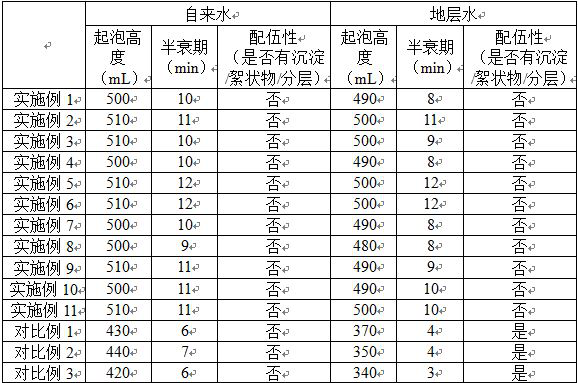

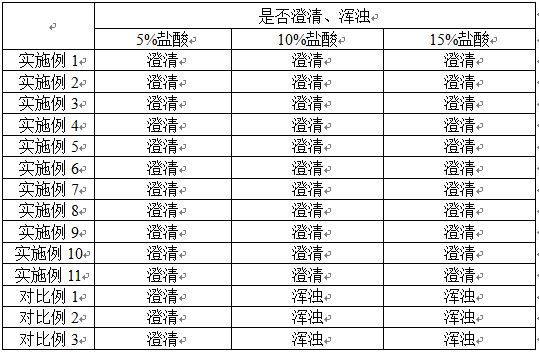

A carbon dioxide and foaming agent technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the foaming agent has poor acid resistance, poor temperature resistance, no biodegradability, and affects the foam stability of foam fracturing fluid. effect and other issues, to achieve the effect of high foaming height and long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A carbon dioxide foam fracturing system foaming agent, based on 100% by weight, including the following raw materials: 38% polyoxyethylated carboxybetaine, 5% sodium fluorocarbon lauryl polyoxyethylene ether ethylene diformate monoester sulfonate , Welan gum 0.05%, ethanol 5%, and the balance is water.

[0024] It can be prepared by mixing and stirring the raw materials evenly.

Embodiment 2

[0026] A carbon dioxide foam fracturing system foaming agent, based on 100% by weight, comprising the following raw materials: polyoxyethylated carboxybetaine 40%, fluorocarbon lauryl polyoxyethylene ether ethylene glycol monoester sulfonate sodium 6% , Welan gum 0.1%, ethanol 5%, and the balance is water.

[0027] It can be prepared by mixing and stirring the raw materials evenly.

Embodiment 3

[0029] A carbon dioxide foam fracturing system foaming agent, based on 100% by weight, including the following raw materials: 42% polyoxyethylenated carboxybetaine, 8% sodium fluorocarbon lauryl polyoxyethylene ether ethylene diformate monoester sulfonate , Welan gum 0.05%, ethanol 7.5%, and the balance is water.

[0030] It can be prepared by mixing and stirring the raw materials evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com