Nitrogen-doped p-type transparent conductive BeZnOS film as well as preparation method and application thereof

A transparent conductive, nitrogen-doped technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of low solubility, low N solubility, instability, etc., and achieve simple equipment and operation process, Effect of increasing doping concentration and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

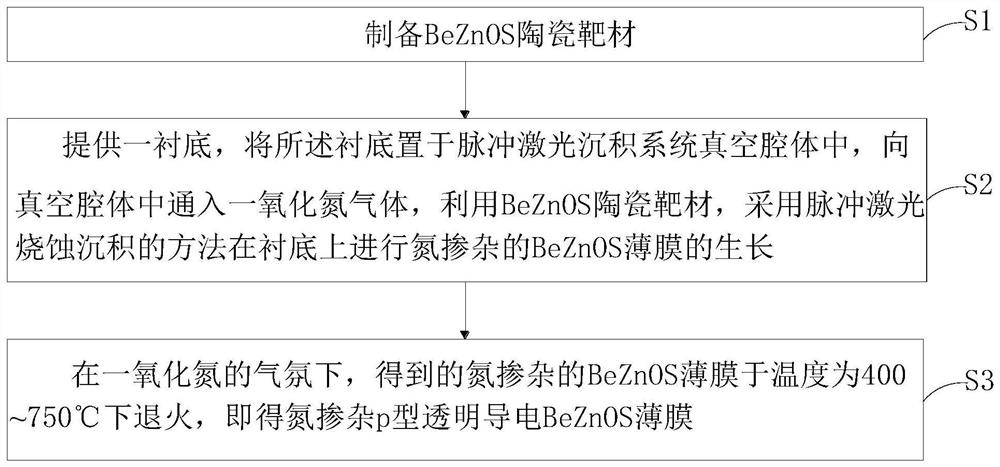

[0033] The invention provides a method for preparing a nitrogen-doped p-type transparent conductive BeZnOS thin film, such as figure 1 shown, including the following steps:

[0034] S1. Preparation of BeZnOS ceramic targets;

[0035] S2. Provide a substrate, place the substrate in the vacuum cavity of the pulsed laser deposition system, pass nitrogen monoxide gas into the vacuum cavity, use the BeZnOS ceramic target material, and adopt the method of pulse laser ablation deposition Nitrogen-doped BeZnOS film growth on the substrate;

[0036] S3. Annealing the obtained nitrogen-doped BeZnOS thin film at a temperature of 400-750° C. in a nitrogen monoxide atmosphere to obtain a nitrogen-doped p-type transparent conductive BeZnOS thin film.

[0037] It should be noted that the preparation method of the BeZnOS ceramic target in the embodiment of the present application includes:

[0038] Weigh ZnS and BeO powders with a molar ratio of 94:6 in a ball mill jar, then add deionized ...

Embodiment 2

[0049] The invention provides a method for preparing a nitrogen-doped p-type transparent conductive BeZnOS thin film, comprising the following steps:

[0050] S1. Preparation of BeZnOS ceramic targets;

[0051] S2. Provide a substrate, place the substrate in the vacuum cavity of the pulsed laser deposition system, pass nitrogen monoxide gas into the vacuum cavity, use the BeZnOS ceramic target material, and adopt the method of pulse laser ablation deposition Nitrogen-doped BeZnOS film growth on the substrate;

[0052] S3. Annealing the obtained nitrogen-doped BeZnOS thin film at a temperature of 400-750° C. in a nitrogen monoxide atmosphere to obtain a nitrogen-doped p-type transparent conductive BeZnOS thin film.

[0053] It should be noted that the preparation method of the BeZnOS ceramic target in the embodiment of the present application includes:

[0054] Weigh ZnS and BeO powders with a molar ratio of 94:6 in a ball mill jar, then add deionized water with 70% of the to...

Embodiment 3

[0064] The invention provides a method for preparing a nitrogen-doped p-type transparent conductive BeZnOS thin film, comprising the following steps:

[0065] S1. Preparation of BeZnOS ceramic targets;

[0066] S2. Provide a substrate, place the substrate in the vacuum cavity of the pulsed laser deposition system, pass nitrogen monoxide gas into the vacuum cavity, use the BeZnOS ceramic target material, and adopt the method of pulse laser ablation deposition Nitrogen-doped BeZnOS film growth on the substrate;

[0067] S3. Annealing the obtained nitrogen-doped BeZnOS thin film at a temperature of 400-750° C. in a nitrogen monoxide atmosphere to obtain a nitrogen-doped p-type transparent conductive BeZnOS thin film.

[0068] It should be noted that the preparation method of the BeZnOS ceramic target in the embodiment of the present application includes:

[0069] Weigh ZnS and BeO powders with a molar ratio of 94:6 in a ball mill jar, then add deionized water with 60% of the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com