Garbage incineration grate furnace based on circulating fluidized bed furnace body

A waste incinerator and circulating fluidized bed technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of not exceeding 3 months, affecting production efficiency and economic benefits, frequent maintenance, etc., to improve production Efficiency and economic benefits, improved continuous running time, effect of small modification workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

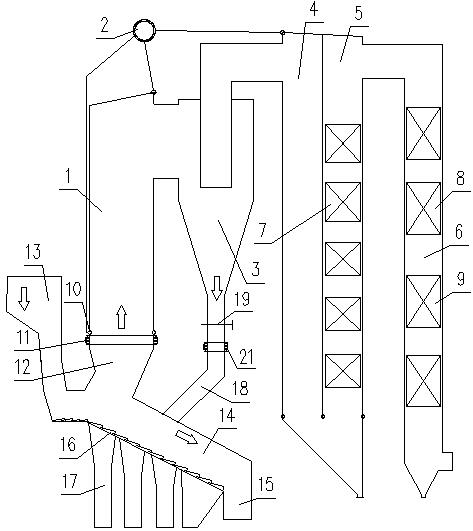

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0011] like figure 1 As shown, the waste incineration grate furnace based on the circulating fluidized bed furnace body of this embodiment includes a furnace 1, a drum 2, a cyclone separator 3, a first shaft flue 4, a second shaft flue 5, and a rear shaft Flue 6, superheater 7, economizer 8 and air preheater 9, the furnace is provided with a lower water-cooled wall header 10; There is an expansion joint 11 between them; one side of the incinerator 12 is connected with a feed port 13, and the other side is connected with a back arch 14 inclined downward from front to back. A pusher grate 16 is provided at the bottom of the feed opening 13 and the back arch 14, and several ash hoppers 17 are arranged under the back arch 14; Flap flap valve 19, expansion joint 21 is provided on return leg 18;

[0012] The present invention retains the circulating fluidized bed furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com