Photochromic adhesive composition, photochromic layered body, and optical article using said photochromic layered body

A photochromic and adhesive technology, applied in the direction of cellulose plastic layered products, color-changing fluorescent materials, synthetic resin layered products, etc., can solve the problem of insufficient adhesion and heat resistance of polycarbonate sheets , Optical article peeling, optical deformation and other problems, to achieve the effect of excellent photochromic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

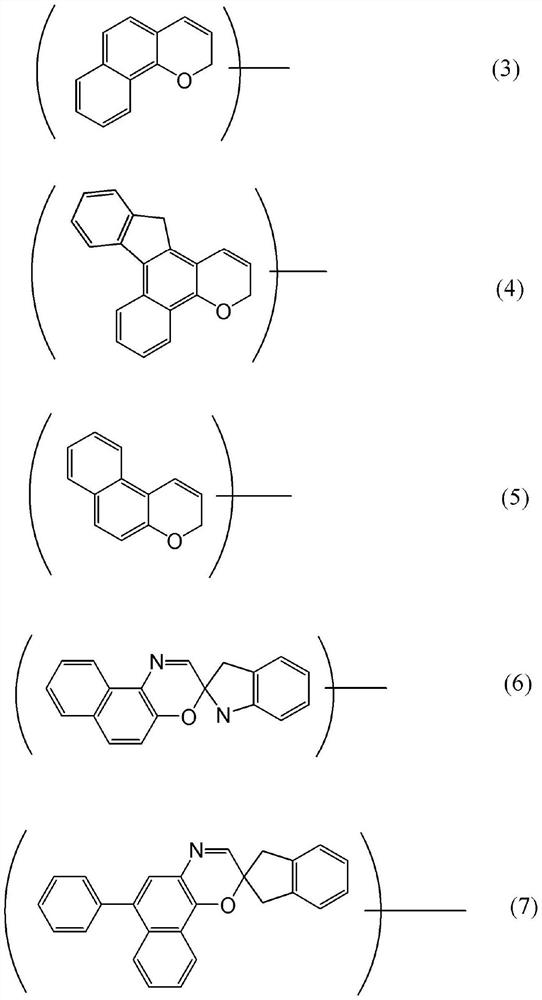

[0323] Preparation of Photochromic Adhesive Composition

[0324] Add 10 g of THF solution of urethane resin (U1), 75 mg of photochromic compound (PC1), 30 mg of trimethylolpropane ((B3) component: H4) as a crosslinking agent, and ethylene oxide as an antioxidant. Bis(oxyethylene)bis[3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate] 25 mg, DOW CORNING TORAY L-700 13 mg as surfactant, at room temperature Stirring and mixing were performed to obtain a mixture for constituting the photochromic adhesive composition. Table 3 shows the compounding ratio of each component.

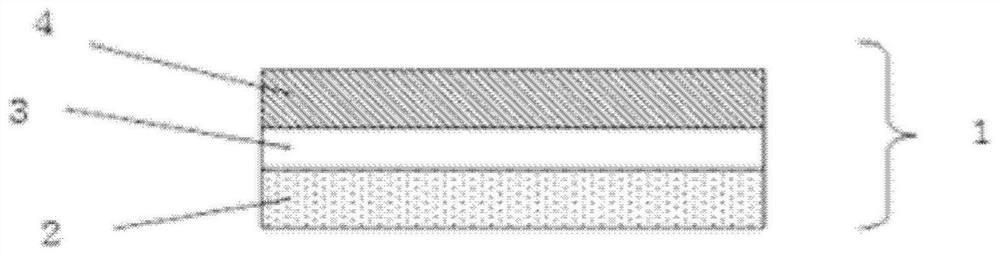

[0325] The above-mentioned mixture containing the organic solvent was coated on a PET (polyethylene terephthalate) film (Purelex film manufactured by Teijin DuPont Membrane Co., Ltd., with a silicon coating film), and dried at 80° C. for 5 Minutes later, the PET film was peeled off to obtain a photochromic adhesive sheet with a thickness of about 40 μm. Next, the obtained photochromic adhesive sheet was sandwiched ...

Embodiment 2

[0352] Preparation of Photochromic Adhesive Composition

[0353] A mixture constituting the photochromic adhesive composition was obtained in the same manner as the preparation of the photochromic adhesive composition (adhesive layer) in Example 1. The fits are shown in Table 3.

[0354] Preparation of adhesive for the second adhesive layer

[0355] 2.5 mg of DOW CORNING TORAY L-7001 was added as a surfactant to 25 g of a propylene glycol monomethyl ether solution of the urethane urea resin (W1) for the second adhesive layer, and stirred and mixed at room temperature to obtain An adhesive for the second adhesive layer.

[0356] Fabrication of Photochromic Laminates

[0357] Polycarbonate having a second adhesive layer with a film thickness of 10 μm was obtained by applying an adhesive for the second adhesive layer on a polycarbonate sheet with a thickness of 300 μm and drying it at 110° C. for 10 minutes. Sheet.

[0358] The above-mentioned mixture constituting the photoc...

Embodiment 3~14

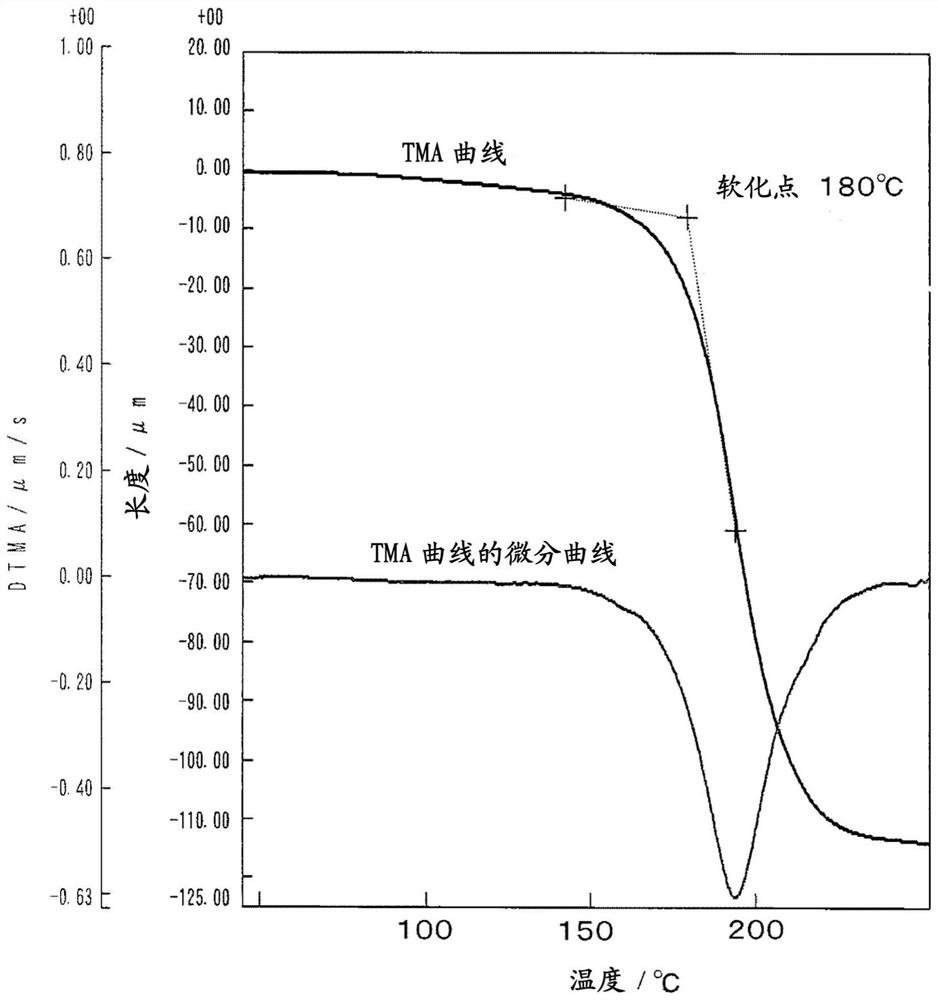

[0362] The same method as in Example 2 was used except that (A) photochromic compound, (B) adhesive urethane (urea) resin, and (B3) active hydrogen-containing compound shown in Table 3 were used A photochromic adhesive composition was prepared. Table 3 shows the softening point of the obtained photochromic adhesive composition measured by the same method as in Examples 1 and 2.

[0363] Moreover, using each photochromic adhesive composition, the photochromic laminated body was produced by the method similar to Example 1 (without the 2nd adhesive layer) or Example 2 (with the 2nd adhesive layer). Table 3 shows the film thickness of the adhesive layer made of the photochromic adhesive composition, the presence or absence of use of the second adhesive layer, and the film thickness. In addition, the obtained photochromic laminate was evaluated in the same manner as in Example 1, and the photochromic properties and peel strength are shown in Table 5, and the bending process and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com