Single-tower multi-stage circulating ammonia/ammonium sulfate flue gas desulfurization method

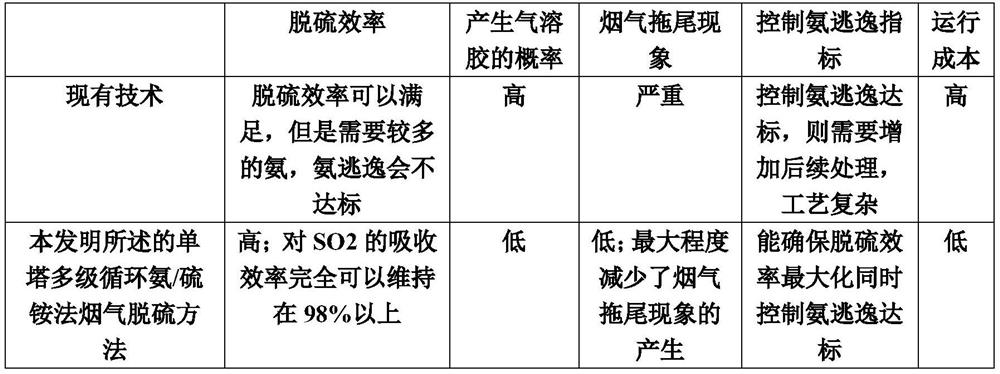

A flue gas and ammonium sulfate technology, which is applied in the field of single-tower multi-stage circulating ammonia/ammonium sulfate flue gas desulfurization, can solve the problems of poor treatment effect, long delay time, difficult control of ammonia water adjustment, etc. The effect of escape, high degree of automation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] The present invention will now be described in detail through this embodiment.

[0095] The single-tower multi-stage circulating ammonia / ammonium sulfate flue gas desulfurization method in this embodiment uses a single-tower multi-stage circulating ammonia / ammonium sulfate flue gas desulfurization system to control ammonia escape and aerosols and meet ultra-low emission standards. An economical, energy-saving, green and environmentally friendly desulfurization system.

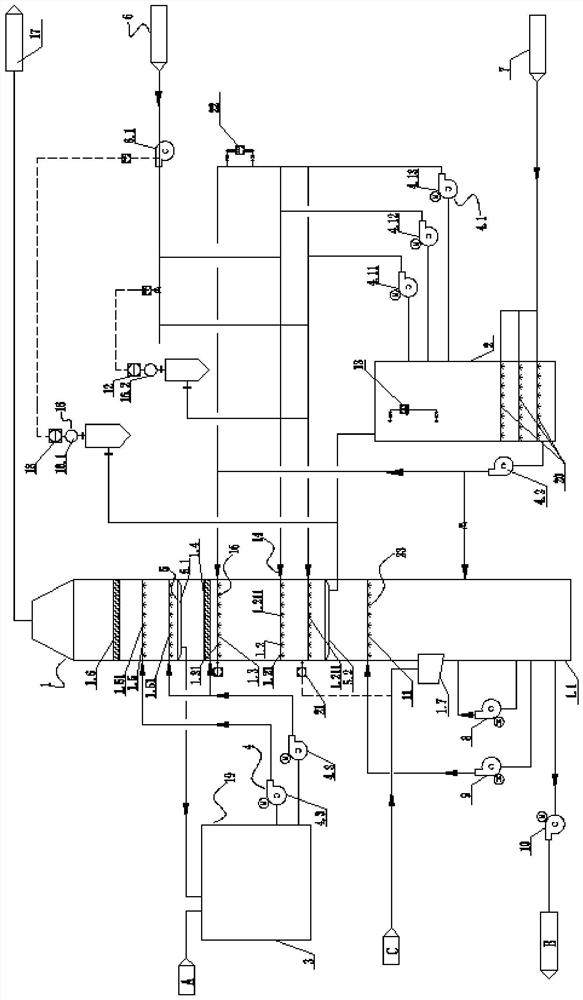

[0096] Referring to the accompanying drawings, it can be seen that the single-tower multi-stage circulating ammonia / ammonium sulfate flue gas desulfurization method in this embodiment adopts a single-tower multi-stage circulating ammonia / ammonium sulfate flue gas desulfurization system, including absorption tower 1, oxidation tank 2, water washing The circulation tank 3 and the circulation pump 4; the oxidation tank 2 and the washing circulation tank 3 are arranged outside the absorption tower 1; The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com