Preparation method for modified urea-formaldehyde resin adhesive low-density rice husk-wood shaving composite plate

A technology of urea-formaldehyde resin glue and wood shavings, which is applied in the field of wood boards, can solve the problems of high density, high glue application, and low cost performance of board making, and achieve the effects of high production efficiency, high economic benefits, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Wash the rice husk once with clean water to remove solid impurities and dust. After air-drying, use a universal grinder to grind and grind the crushed rice husk through a 15-mesh sieve. impurities such as powder and dust to obtain qualified raw materials;

[0027] (2) Weigh rice husk powder and wood shavings in step (1) and mix them in a mass ratio of 1:1, put them into a dryer at 103° C. and dry for 30 hours to reduce the water content to 3%;

[0028] (3) first mix urea-formaldehyde resin with mass concentration 25% NH 4 It is made by mixing Cl aqueous solution, urea-formaldehyde resin and curing agent NH 4 The mass ratio of Cl is 1:99, obtains urea-formaldehyde resin glue;

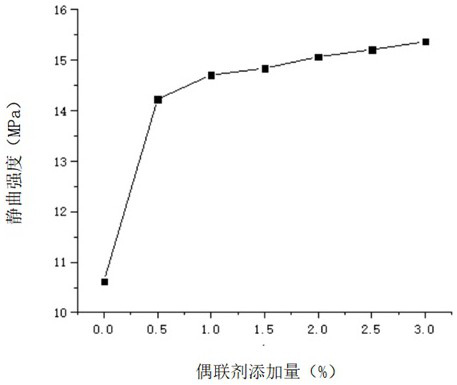

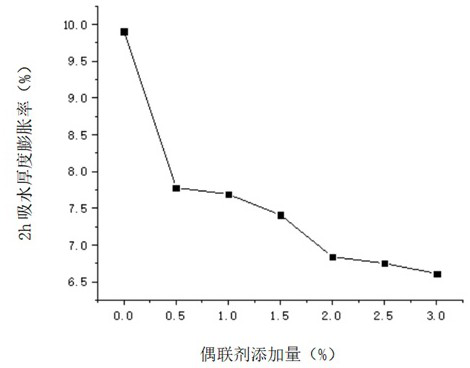

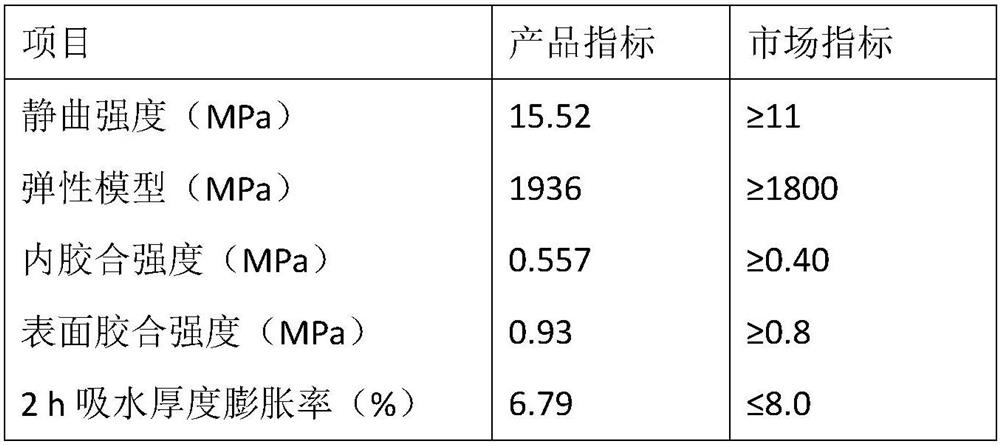

[0029] Put the mixture of rice husk and wood shavings into the glue mixer, turn on the power, open the vent valve, and pour the KH-550 coupling agent and urea-formaldehyde resin glue into the rubber tube at a uniform speed. The amount of the coupling agent added is 2.5% of the mixture mass. ...

Embodiment 2

[0036] (1) Wash the rice husk twice with clean water to remove solid impurities and dust. After air-drying, use a universal grinder to grind and grind the crushed rice husk through a 10-mesh sieve. impurities such as powder and dust to obtain qualified raw materials;

[0037] (2) Weigh rice husk powder and wood shavings in step (1) and mix them according to the mass ratio of 1:1.2, put them into a dryer at 100° C. and dry for 24 hours to reduce the water content to 5%;

[0038] (3) first mix urea-formaldehyde resin with mass concentration 25% NH 4 It is made by mixing Cl aqueous solution, urea-formaldehyde resin and curing agent NH 4 The mass ratio of Cl is 2:98, obtains urea-formaldehyde resin glue;

[0039] Put the mixture of rice husk and wood shavings into the glue mixer, turn on the power, open the vent valve, and pour the KH-550 coupling agent and urea-formaldehyde resin glue into the rubber hose at a uniform speed. The amount of the coupling agent added is 3% of the mas...

Embodiment 3

[0046] (1) Wash the rice husk 3 times with water to remove solid impurities and dust. After air-drying, use a universal grinder to grind and grind the crushed rice husk through a 18-mesh screen. The size of the wood shavings is larger than 25 mesh, and the small impurities such as powder and dust to obtain qualified raw materials;

[0047] (2) Weigh the rice husk powder and wood shavings in the step (1) and mix them in a mass ratio of 1:1.5, put them into a dryer at 105° C. and dry for 27 hours to reduce the water content to 4%.

[0048] (3) first mix urea-formaldehyde resin with mass concentration 25% NH 4 It is made by mixing Cl aqueous solution, urea-formaldehyde resin and curing agent NH 4 The mass ratio of Cl is 1:99, obtains urea-formaldehyde resin glue;

[0049] Put the mixture of rice husk and wood shavings into the glue mixer, turn on the power, open the vent valve, and pour the KH-550 coupling agent and urea-formaldehyde resin glue into the rubber tube at a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com