Structural height calculation method for focused ion beam assisted deposition processing

A focused ion beam and assisted deposition technology, which is applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as etching, reduction of precursor gas concentration, and inability to accurately calculate the height of the final processing structure to achieve accurate calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

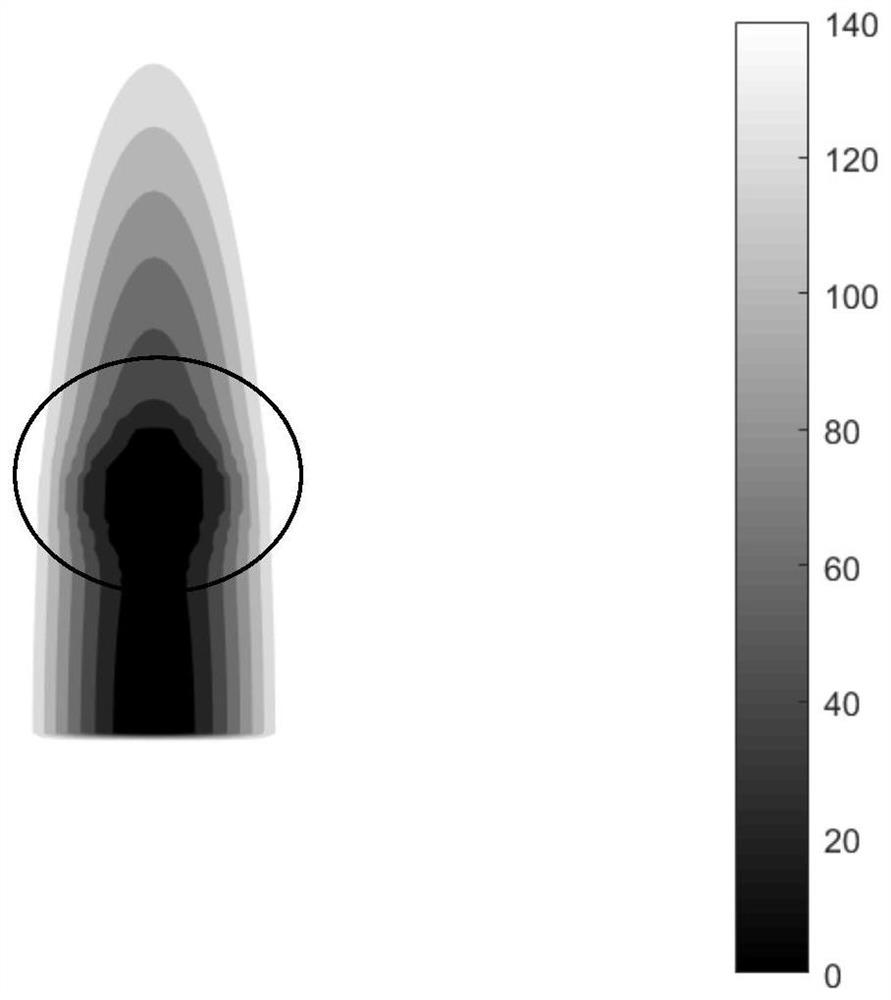

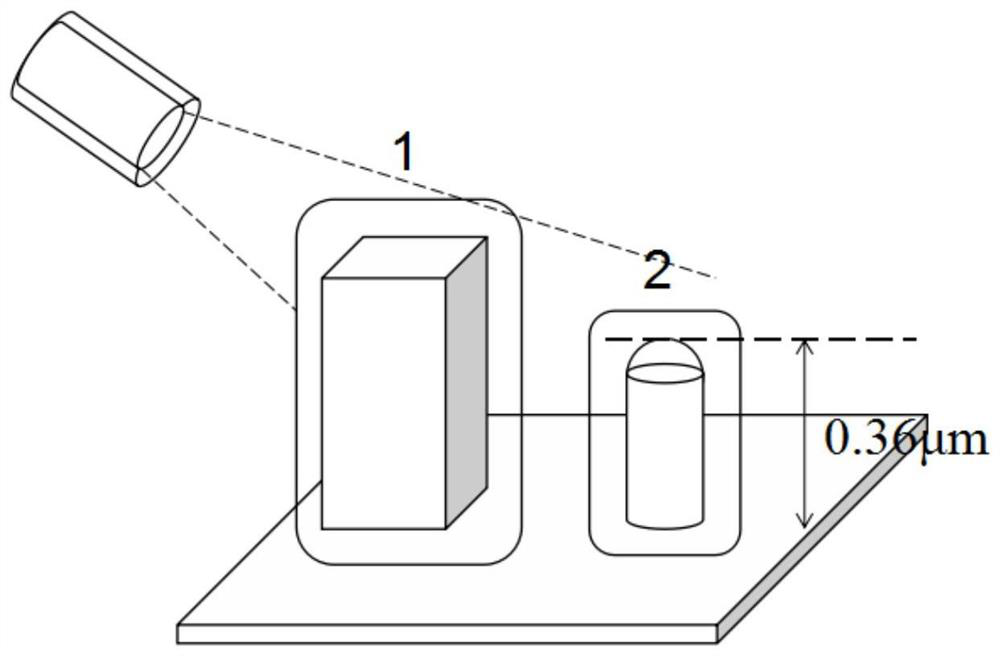

[0059] Research objective: There is a cube structure with a structure size of 0.3μm×0.3μm×0.6μm. The height h between the gas phase tube and the sample is 150 μm, and the offset distance b s = 410 μm. The processed structure is 0.3 μm away from the existing structure. The total processing time is 120s. Reproduces the shadow effect of machined structures.

[0060] S1. Add the following attributes to the precursor gas diffusion model: whether the diffusion index, the precursor gas adsorption probability. The resolution of the cells in the precursor gas diffusion model is 10nm×10nm×10nm.

[0061] S2. Capture the outline of the existing structure in the continuous cellular automaton, and set the diffusion index corresponding to the element attribute in the precursor gas diffusion model to 0. In the precursor gas diffusion model, i 1 = 0, i 2 =30,j 1 = 45,j 2 =75.

[0062] S3. Determine the shadow blocking area according to the existing structure outline and the parameter...

Embodiment 2

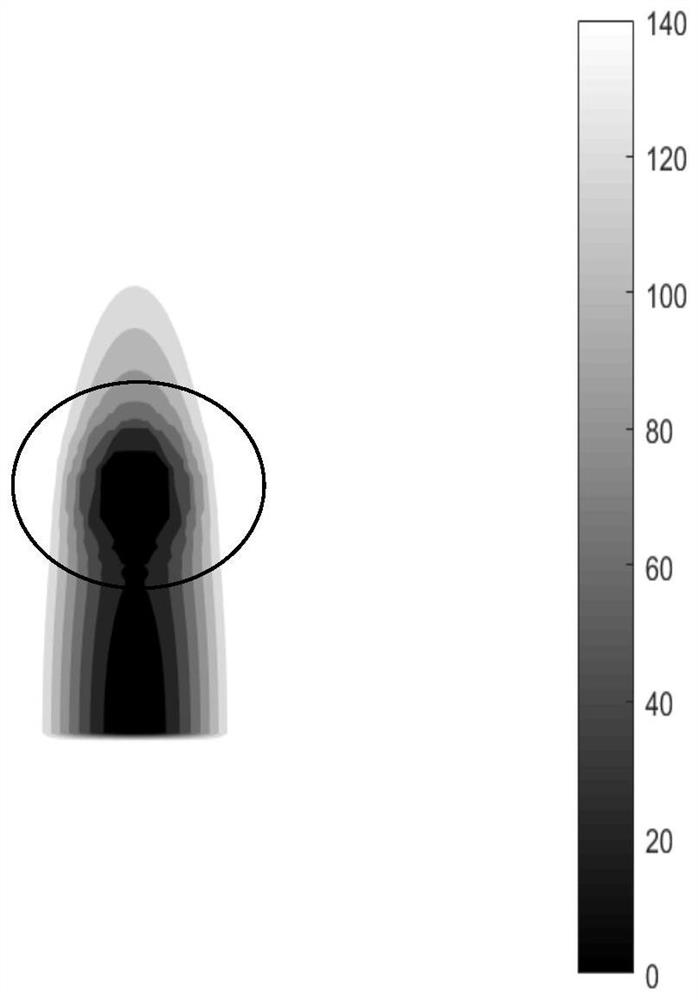

[0079] Research objective: There is a cube structure with a structure size of 0.3μm×0.3μm×0.6μm. The height h between the gas phase tube and the sample is 150 μm, and the offset distance b s = 150 μm. The processed structure is 0.3 μm away from the existing structure. The total processing time is 120s. Reproduces the shadow effect of machined structures.

[0080] S1. Add the following attributes to the precursor gas diffusion model: whether the diffusion index, the precursor gas adsorption probability. The resolution of the cells in the precursor gas diffusion model is 10nm×10nm×10nm.

[0081] S2. Capture the outline of the existing structure in the continuous cellular automaton, and set the diffusion index corresponding to the element attribute in the precursor gas diffusion model to 0. In the precursor gas diffusion model, i 1 = 0,i 2 =30,j 1 = 45,j 2 =75.

[0082] S3. Determine the shadow blocking area according to the existing structure outline and the parameters...

Embodiment 3

[0103] Research objective: There is a cube structure with a structure size of 0.3μm×0.3μm×0.6μm. The height h between the gas phase tube and the sample is 150 μm, and the offset distance b s = 410 μm. The processed structure is 0.5 μm away from the existing structure. Reproduces the shadow effect of machined structures.

[0104] S1. Add the following attributes to the precursor gas diffusion model: whether the diffusion index, the precursor gas adsorption probability. The resolution of the cells in the precursor gas diffusion model is 10nm×10nm×10nm.

[0105] S2. Capture the outline of the existing structure in the continuous cellular automaton, and set the diffusion index corresponding to the element attribute in the precursor gas diffusion model to 0. In the precursor gas diffusion model, i 1 = 0,i 2 =30,j 1 = 45,j 2 =75.

[0106] S3. Determine the shadow blocking area according to the existing structure outline and the parameters of the gas phase tube. with struct...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap