Brick making machine for producing baking-free brick from mineral tailings

A technology for brick presses and burn-free bricks, which is applied in the field of brick presses and can solve problems such as size adjustment that cannot be pressed without burn-free bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

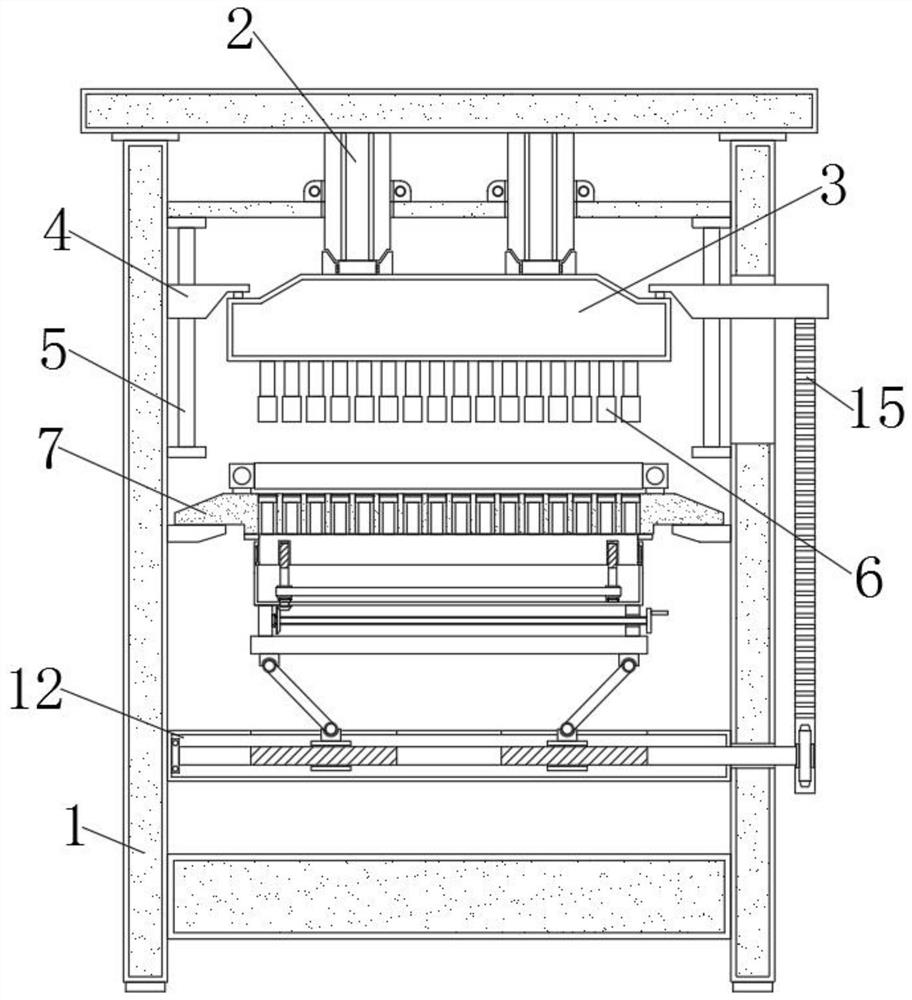

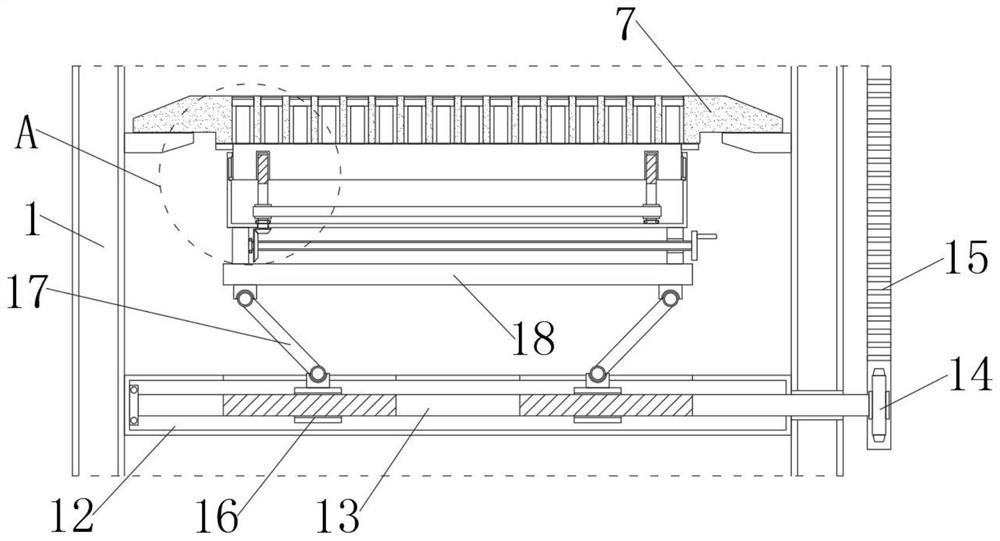

[0033] According to attached figure 1 , attached figure 2 , attached Figure 7 And attached Figure 9 As shown, a brick press for producing non-fired bricks from mineral tailings includes a brick press main body 1, a hydraulic cylinder 2, a top plate 3, a first sliding sleeve 4, a first sliding rod 5, a brick pressing plate 6, The brick pressing mold 7, the brick opening 8, the conveyor belt 9, the motor 10 and the main shaft 11, the hydraulic cylinder 2 is fixedly installed on both sides of the top of the main body of the brick press 1, and the bottom end of the hydraulic cylinder 2 is fixedly installed with a top plate 3, Both sides of the top plate 3 are welded with a first sliding sleeve 4, and the inside of the first sliding sleeve 4 is slidably connected with a first sliding rod 5, and both ends of the first sliding rod 5 are fixedly installed on the inner wall of the brick press main body 1. On both sides, the bottom end of the top plate 3 is fixedly equipped with a...

Embodiment 2

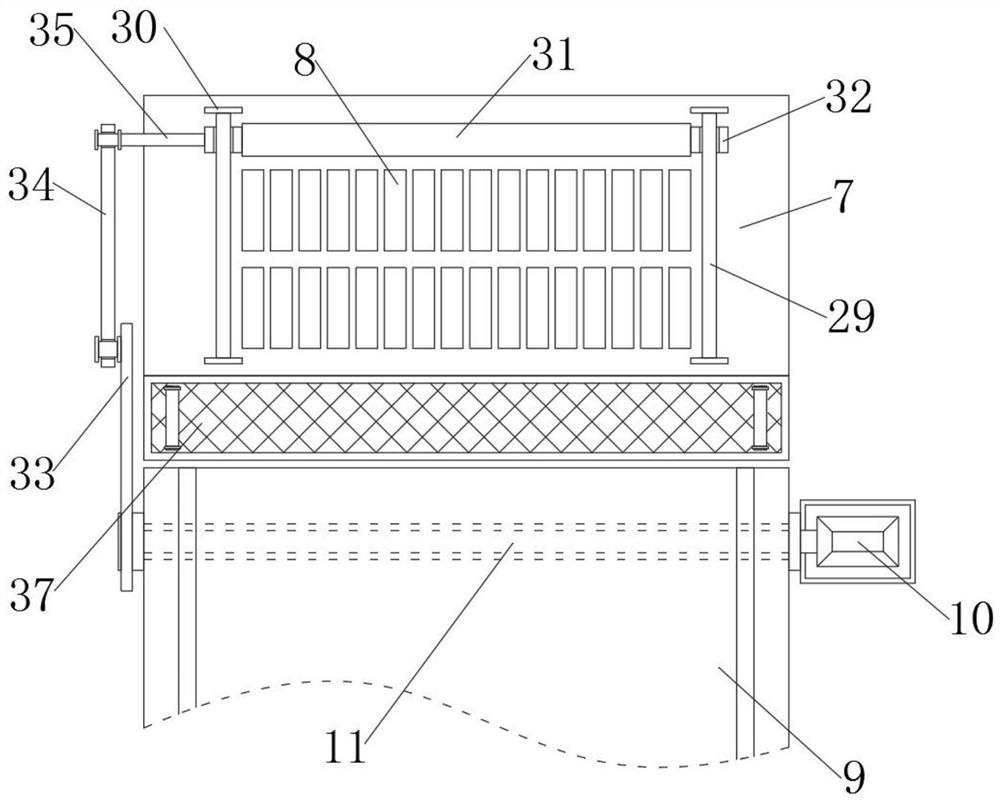

[0035] According to attached image 3 And attached Figure 4 As shown, the pushing mechanism includes a second sliding rod 29, a baffle plate 30, a push plate 31, a second sliding sleeve 32, a centrifugal rod 33, a hinged rod 34 and a connecting rod 35, and both sides above the brick pressing mold 7 are provided with a second Two slide bars 29, and the front and rear sides of the second slide bar 29 are all fixedly equipped with baffle plates 30, the bottom ends of the baffle plates 30 are all welded on the upper surface of the brick pressing mold 7, two groups of second slide bars 29 are close One side is provided with a push plate 31, and both sides of the push plate 31 are fixedly installed with a second sliding sleeve 32, and the second sliding sleeve 32 is sleeved on the outside of the second sliding rod 29, and the second sliding rod 29 and the second sliding rod 29 The two sliding sleeves 32 are slidingly connected, and the side of the main shaft 11 away from the motor...

Embodiment 3

[0037] According to attached Figure 5 And attached Figure 8 As shown, the collection mechanism includes a collection tank 36, a filter screen 37, a first partition 38, a slide rail 39, a slider 40, a pull rod 41, a first spring 42, a second partition 43, a block 44 and a collection box 45, The front end of the brick pressing mold 7 is provided with a collecting tank 36, and a filter screen 37 is placed on the top of the collecting tank 36, the bottom end of the brick pressing mold 7 is fixedly equipped with a first partition 38, and the front end of the brick pressing mold 7 bottom is opened There is a slide rail 39, the inside of the slide rail 39 is slidingly connected with a slide block 40, and the front end of the slide block 40 is fixedly equipped with a pull rod 41, the outside of the pull rod 41 is wound with a first spring 42, and the front and rear sides of the first spring 42 are respectively Welded on the slide rail 39 and the slider 40, the bottom end of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com