Method for producing asymmetric fiber supercapacitor electrode, produced electrode and supercapacitor

A supercapacitor and asymmetric technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of high cost of asymmetric fiber supercapacitor electrodes, unsatisfactory electrochemical performance, and complicated preparation process. Achieve excellent electrochemical performance, wide operating voltage window, simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of method that takes carbon fiber as substrate to prepare asymmetric fiber supercapacitor electrode in situ

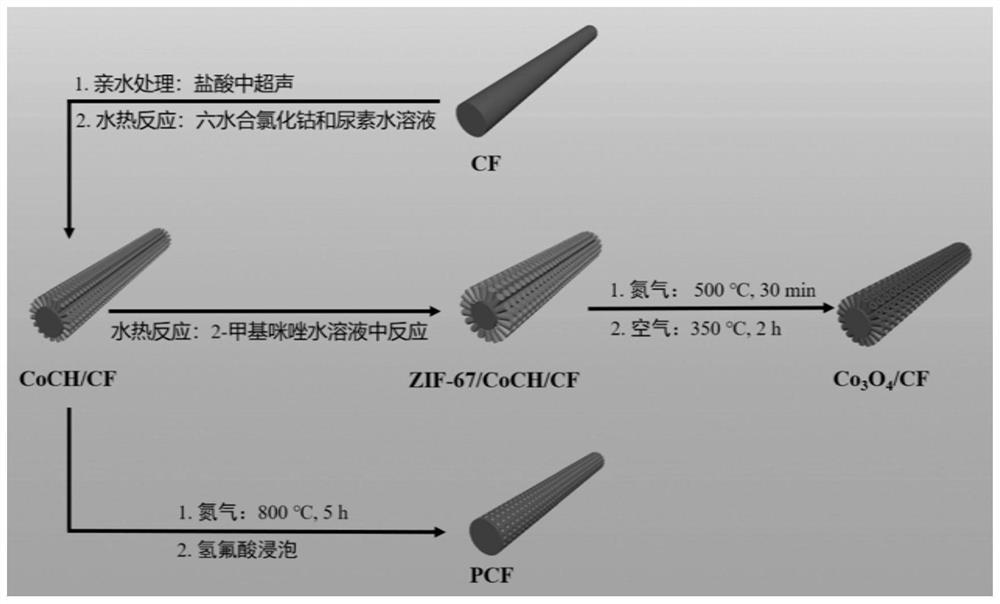

[0051] figure 1 In order to prepare tricobalt tetroxide / carbon fiber array (Co 3 o 4 / CF) and porous carbon fiber (PCF).

[0052] S1. Sonicate the carbon fibers in 3M hydrochloric acid solution for 30 minutes, and then alternately wash them in water and ethanol;

[0053] S2. 1.1896g cobalt chloride hexahydrate and 1.5g urea were stirred in 20mL water to obtain a solution;

[0054] S3. Transfer the solution and carbon fiber prepared in step S2 to a polytetrafluoroethylene-lined stainless steel autoclave, seal and keep it at 90°C for 10h, then cool to room temperature, take it out, wash and dry at room temperature, and obtain carbon fiber grown on the carbon fiber Basic cobalt carbonate nanoarrays (CoCH / CF);

[0055] S4. Immerse the CoCH / CF prepared in step S3 into 0.125g mL -1 In the 2-methylimidazole aqueous solution of 5h, due to the f...

Embodiment 2

[0058] The characterization of embodiment 2 single electrode

[0059] 1. Experimental method

[0060] The S-4800 scanning electron microscope was used for SEM morphology characterization of the sample prepared in Example 1. The electrochemical performance test was carried out on Shanghai Chenhua CHI760E electrochemical workstation, wherein the platinum wire electrode was used as the counter electrode, the Ag / AgCl electrode was used as the reference electrode, and the sample Co prepared in Example 1 was 3 o 4 / CF and PCF were used as working electrodes, and 6M KOH solution was used as electrolyte.

[0061] 2. Experimental results

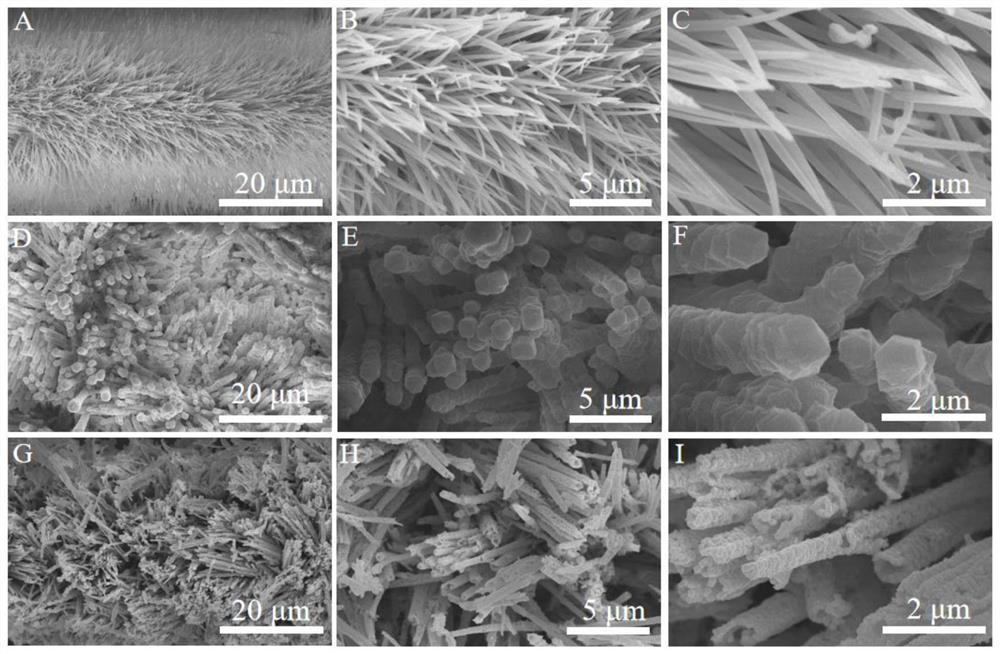

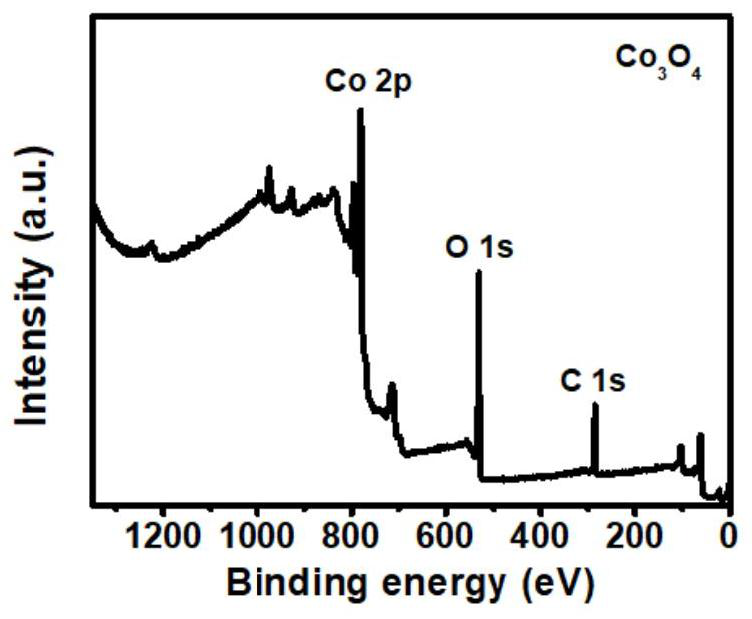

[0062] (1) figure 2 The A-C picture is the SEM picture of CoCH / CF. From the picture, it can be seen that CoCH grows neatly on the carbon fiber; figure 2 The D-F picture is the SEM picture of ZIF-67 / CoCH / CF, and it can be seen from the picture that ZIF-67 is coated on CoCH; figure 2 The G-I diagram is cobalt tetroxide / carbon fiber array elect...

Embodiment 3

[0064] Embodiment 3 Asymmetric Fiber Supercapacitor

[0065] 1. Preparation method

[0066] The tricobalt tetroxide / carbon fiber array (Co 3 o 4 / CF) and porous carbon fiber (PCF) to prepare an asymmetric fiber supercapacitor (ASC), specifically through the following methods:

[0067] The fiber positive electrode (Co 3 o 4 / CF) and the fiber negative electrode (PCF) were wrapped with a layer of separator (CNF gel), and dried at room temperature; then soaked in 6M KOH electrolyte to swell; finally, the two fiber positive and negative electrodes were wound together and packaged in in a plastic bag with platinum wire as the lead.

[0068] 2. Electrochemical performance test of supercapacitor

[0069] (1) Figure 7 For the electrochemical performance test of asymmetric fiber supercapacitor (ASC), where Figure 7 Figure A is the cyclic voltammetry curves of the asymmetric fiber supercapacitor (ASC) at different scan rates, showing a good charge and discharge process; Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Than electricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com